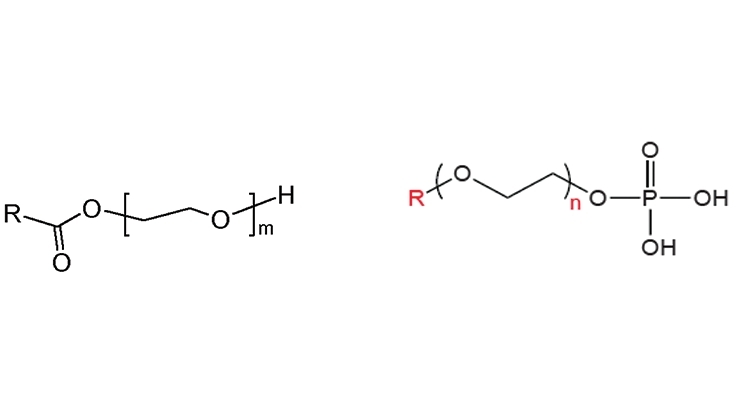

Alcohol ethoxylates (AEs) are non-ionic surfactants produced by reacting fatty alcohols with ethylene oxide. They have excellent wetting, emulsifying, dispersing and solubilizing properties. AEs produce stable solutions and emulsions with oils, fats, waxes and resins. They are used in various applications including industrial and institutional cleaners, personal care products, agricultural chemicals, paints and coatings.

AE Production and Raw Materials

Global Alcohol Ethoxylates are manufactured through a straightforward ethoxylation reaction process. The common fatty alcohols used for production are C12-C15 alcohols derived from natural fats and oils. Ethylene oxide is used for the ethoxylation reaction which produces a range of ethoxymer mixtures depending on the degree of ethoxylation. AE production facilities are located worldwide with major centers in North America, Europe and Asia Pacific. The global AE production capacity is over 1.5 million metric tons per year.

Paints and Coatings Applications

AEs see wide use in paints and coatings due to their effectiveness in reducing surface tension and enhancing the spreading properties of various formulations. They enable easier application and improved substrate wetting. AEs are utilized in water-based architectural paints, industrial protective coatings, wood stains and other coating types. Their global demand from the paints sector is projected to increase steadily at 3-4% annually through 2025.

Personal Care Product Applications

As mild and skin-friendly nonionics, AEs are versatile ingredients widely employed in personal care products. They are used as emulsifiers in creams, lotions and other cosmetic formulations. AEs enable the creation of stable oil-in-water emulsions for these products. They are also utilized as solubilizers and preservatives boosters. North America and Europe currently account for over 50% of the total AE demand from the personal care industry.

Get More Insights on- Global Alcohol Ethoxylates