Saltegra is a process safety & risk management consulting firm that helps companies achieve their business goals while reducing and managing risk through sustainable and adaptable operational risk management solutions. We partner with our clients so they can confidently move through the ambiguity of process safety and risk management compliance.

We leverage both our multi-disciplinary body of knowledge and industry technical expertise to provide value to our clients through reliable methodologies, efficiency tools, and effective collaboration.

We leverage both our multi-disciplinary body of knowledge and industry technical expertise to provide value to our clients through reliable methodologies, efficiency tools, and effective collaboration.

-

9 Yazı

-

4 Fotoğraflar

-

0 Videolar

-

Ardından: 0 people

© 2025 Bresdel

Turkish

Turkish

Mashable is a global, multi-platform media and entertainment company

For more queries and news contact us on this

Email: info@mashablepartners.com

Son Güncellemeler

-

Hazard Vs. Risk : What is the difference?

Hazard is any source of potential harm or damage to humans, to property, to the environment or a combination of these. Hazard can be a thing, a condition, or a behavior. Generally, it is anything that can cause harm. Sometimes the effect is referred to as a hazard instead of the actual source of the consequence. For example, the COVID-19 might be called a hazard by some, but in general, the Corona Virus is considered a hazard or hazardous biological agent.

Risk is the possibility of something bad happening if exposed to a hazard. It refers to the chance that the person will be harmed or injured, the environment will be affected or the property will be damaged if exposed to the hazard. Risks are expressed in probability or likelihood of developing a consequence like a disease and an injury.

It is also important to determine the hazard and the potential harm it can cause to eliminate risk. However, the hazard may remain even if the risk is minimized. These can be further understood through Hazard Identification and Risk Assessment and Control which aims to determine hazards, level of risk, and how to control the effect.

Interested? Check out https://saltegra.com/process-safety-concepts/hazards-vs-risks/ for more information!Hazard Vs. Risk : What is the difference? Hazard is any source of potential harm or damage to humans, to property, to the environment or a combination of these. Hazard can be a thing, a condition, or a behavior. Generally, it is anything that can cause harm. Sometimes the effect is referred to as a hazard instead of the actual source of the consequence. For example, the COVID-19 might be called a hazard by some, but in general, the Corona Virus is considered a hazard or hazardous biological agent. Risk is the possibility of something bad happening if exposed to a hazard. It refers to the chance that the person will be harmed or injured, the environment will be affected or the property will be damaged if exposed to the hazard. Risks are expressed in probability or likelihood of developing a consequence like a disease and an injury. It is also important to determine the hazard and the potential harm it can cause to eliminate risk. However, the hazard may remain even if the risk is minimized. These can be further understood through Hazard Identification and Risk Assessment and Control which aims to determine hazards, level of risk, and how to control the effect. Interested? Check out https://saltegra.com/process-safety-concepts/hazards-vs-risks/ for more information! SALTEGRA.COMHazards vs Risks - SaltegraSaltegra Consulting LLC provides helpful information about the difference between hazards and risks. Visit our website today to read the full article.0 Yorumlar 0 hisse senetleri 272 Views 0 önizlemePlease log in to like, share and comment!

SALTEGRA.COMHazards vs Risks - SaltegraSaltegra Consulting LLC provides helpful information about the difference between hazards and risks. Visit our website today to read the full article.0 Yorumlar 0 hisse senetleri 272 Views 0 önizlemePlease log in to like, share and comment! -

Process safety incidents have historically been a significant concern across various industries in the USA, with notable occurrences in petrochemicals, storage, oil refining, offshore oil and gas, and chemicals. These industries, encompassing complex processes and the handling of hazardous materials, face challenges leading to unforeseen events and significant consequences.

The petrochemical industry is a crucial part of the process industries, focusing on turning raw materials from petroleum and natural gas into useful products, like plastics and synthetic fibers. It involves various units and equipment, such as reactors, towers, heaters, and storage tanks.

Storage facilities, essential for housing a variety of materials, face incidents marked by overpressure and explosive decompositions. The stored materials, including hazardous substances like ammonium nitrate, pose serious risks. Incidents in storage industries can result in on-site fatalities and environmental effects, highlighting the importance of stringent safety measures.

The oil refining industry, a key player among process industries, is responsible for converting crude oil into a variety of essential products, including gasoline, diesel, and petrochemicals. This intricate process involves various units and equipment, such as distillation columns, reactors, and storage tanks.

Read more on https://saltegra.com/process-hazard-analysis/process-industries-safety-incidents-usa/.Process safety incidents have historically been a significant concern across various industries in the USA, with notable occurrences in petrochemicals, storage, oil refining, offshore oil and gas, and chemicals. These industries, encompassing complex processes and the handling of hazardous materials, face challenges leading to unforeseen events and significant consequences. The petrochemical industry is a crucial part of the process industries, focusing on turning raw materials from petroleum and natural gas into useful products, like plastics and synthetic fibers. It involves various units and equipment, such as reactors, towers, heaters, and storage tanks. Storage facilities, essential for housing a variety of materials, face incidents marked by overpressure and explosive decompositions. The stored materials, including hazardous substances like ammonium nitrate, pose serious risks. Incidents in storage industries can result in on-site fatalities and environmental effects, highlighting the importance of stringent safety measures. The oil refining industry, a key player among process industries, is responsible for converting crude oil into a variety of essential products, including gasoline, diesel, and petrochemicals. This intricate process involves various units and equipment, such as distillation columns, reactors, and storage tanks. Read more on https://saltegra.com/process-hazard-analysis/process-industries-safety-incidents-usa/. SALTEGRA.COMProcess Industries With the Most Safety IncidentsLearn about the process industries with the most safety incidents through Saltegra Consulting LLC. Visit our website today to read the full article.0 Yorumlar 0 hisse senetleri 1K Views 0 önizleme

SALTEGRA.COMProcess Industries With the Most Safety IncidentsLearn about the process industries with the most safety incidents through Saltegra Consulting LLC. Visit our website today to read the full article.0 Yorumlar 0 hisse senetleri 1K Views 0 önizleme -

Layers of Protection Analysis (LOPA) is a risk management methodology used to assess hazardous scenarios and incidents. In simple terms, it involves systematically comparing scenario risk estimates against predetermined risk criteria to discern the need for additional risk reduction measures.

LOPA Terminologies

Likelihood

Likelihood refers to the probability of an event occurring in a specific context. It helps in determining how often something undesirable might happen, guiding the implementation of preventive measures.

Severity

Severity measures the extent of harm or damage that could result from an undesired event. It assesses the impact on safety, the environment, and the business, helping organizations align potential consequences with acceptable risk levels.

Risk

Risk combines the likelihood and severity of undesired events in a process. It is often represented by a matrix, where severity and frequency align on the axes, categorizing risks into tolerable, marginal, or unacceptable levels.

Risk Tolerance

Risk tolerance is the level of potential consequences an individual or organization is willing to accept. Understanding this helps in making decisions that align with acceptable risk levels.

Risk Reduction Factor

The Risk Reduction Factor (RRF) measures how much a protective function lowers the frequency of a hazard scenario. It is the reciprocal of the average probability of failure on demand and relates to different frequency categories or event occurrence rates.

Safeguards

Safeguards are protective measures designed to prevent or mitigate the consequences of potential hazards or events within a process or system. These measures act as barriers to reduce the risk of undesired incidents.

Independent Protection Layers (IPLs)

Independent protection layers refer to specific safeguards or barriers within a system that act autonomously from other protective measures. IPLs provide an additional level of defense to ensure that the risk associated with a hazard is reduced to an acceptable level.

Source: https://saltegra.com/lopa/lopa-training-usa/Layers of Protection Analysis (LOPA) is a risk management methodology used to assess hazardous scenarios and incidents. In simple terms, it involves systematically comparing scenario risk estimates against predetermined risk criteria to discern the need for additional risk reduction measures. LOPA Terminologies Likelihood Likelihood refers to the probability of an event occurring in a specific context. It helps in determining how often something undesirable might happen, guiding the implementation of preventive measures. Severity Severity measures the extent of harm or damage that could result from an undesired event. It assesses the impact on safety, the environment, and the business, helping organizations align potential consequences with acceptable risk levels. Risk Risk combines the likelihood and severity of undesired events in a process. It is often represented by a matrix, where severity and frequency align on the axes, categorizing risks into tolerable, marginal, or unacceptable levels. Risk Tolerance Risk tolerance is the level of potential consequences an individual or organization is willing to accept. Understanding this helps in making decisions that align with acceptable risk levels. Risk Reduction Factor The Risk Reduction Factor (RRF) measures how much a protective function lowers the frequency of a hazard scenario. It is the reciprocal of the average probability of failure on demand and relates to different frequency categories or event occurrence rates. Safeguards Safeguards are protective measures designed to prevent or mitigate the consequences of potential hazards or events within a process or system. These measures act as barriers to reduce the risk of undesired incidents. Independent Protection Layers (IPLs) Independent protection layers refer to specific safeguards or barriers within a system that act autonomously from other protective measures. IPLs provide an additional level of defense to ensure that the risk associated with a hazard is reduced to an acceptable level. Source: https://saltegra.com/lopa/lopa-training-usa/ SALTEGRA.COMLayer of Protection Analysis (LOPA) Training Course | USASaltegra Consulting LLC offers Layer of Protection Analysis (LOPA) and LOPA training in the USA. Visit our website today for more information.0 Yorumlar 0 hisse senetleri 415 Views 0 önizleme

SALTEGRA.COMLayer of Protection Analysis (LOPA) Training Course | USASaltegra Consulting LLC offers Layer of Protection Analysis (LOPA) and LOPA training in the USA. Visit our website today for more information.0 Yorumlar 0 hisse senetleri 415 Views 0 önizleme -

The Washington State Department of Labor and Industries (L&I) has proposed a new rule aimed at updating process safety management (PSM) standards specifically for petroleum refineries. The proposed regulation introduces several noteworthy changes to Washington’s PSM, and these requirements are comparable to the deviations from the federal standards enacted in California in 2017. Some key elements of the proposed rule include:

- Expanding the Scope of Process Hazard Analyses (PHA)

- Management of Organizational Changes (MOOCs)

- Inclusion of Human Factors

- Root Cause Analyses (RCA)

- Process Safety Culture Assessment

- Definition of Recognized and Generally Accepted Good Engineering Practices (RAGAGEP)

Read more on https://saltegra.com/industry-insights-and-featured-topics/proposed-rule-update-for-petroleum-refinery-psm-in-washington-state/.The Washington State Department of Labor and Industries (L&I) has proposed a new rule aimed at updating process safety management (PSM) standards specifically for petroleum refineries. The proposed regulation introduces several noteworthy changes to Washington’s PSM, and these requirements are comparable to the deviations from the federal standards enacted in California in 2017. Some key elements of the proposed rule include: - Expanding the Scope of Process Hazard Analyses (PHA) - Management of Organizational Changes (MOOCs) - Inclusion of Human Factors - Root Cause Analyses (RCA) - Process Safety Culture Assessment - Definition of Recognized and Generally Accepted Good Engineering Practices (RAGAGEP) Read more on https://saltegra.com/industry-insights-and-featured-topics/proposed-rule-update-for-petroleum-refinery-psm-in-washington-state/. SALTEGRA.COMProposed Petroleum Refinery PSM Rule Update | USAThe State of Washington has proposed rule updates for the PSM standards of petroleum refineries. Learn more on the Saltegra Consulting LLC website.0 Yorumlar 0 hisse senetleri 485 Views 0 önizleme

SALTEGRA.COMProposed Petroleum Refinery PSM Rule Update | USAThe State of Washington has proposed rule updates for the PSM standards of petroleum refineries. Learn more on the Saltegra Consulting LLC website.0 Yorumlar 0 hisse senetleri 485 Views 0 önizleme -

Effects of Chemical Spills on People and the Environment

Chemical spills have a significant impact on the environment. It can be dangerous to human beings and animals. Learn how Process Hazard Analysis (PHA) can help reduce the probability of these incidents occurring.

Visit our page today!

https://www.saltegra.comEffects of Chemical Spills on People and the Environment Chemical spills have a significant impact on the environment. It can be dangerous to human beings and animals. Learn how Process Hazard Analysis (PHA) can help reduce the probability of these incidents occurring. Visit our page today! https://www.saltegra.com0 Yorumlar 0 hisse senetleri 372 Views 0 önizleme -

Safeguards help to protect a process when the system deviates from the safe operating conditions.SAFEGUARD A safeguard is any safety device that would either interrupt the chain of events following an initiating event to prevent a consequence from occurring or would reduce the severity of a consequence, and overall reduce the risk. Safeguards can be devices, systems, or actions performed by a person/operator. Types of Safeguards Preventative A Preventative Safeguard is a safeguard that can...0 Yorumlar 0 hisse senetleri 2K Views 0 önizleme

-

In order to study a system of a Process Hazard Analysis (PHA) or Hazard and Operability Study (HAZOPs), it must first be divided into nodes or sections for detailed review. Usually, these nodes include a certain section of piping, valves, and equipment.

Visit our website now! https://www.saltegra.com/In order to study a system of a Process Hazard Analysis (PHA) or Hazard and Operability Study (HAZOPs), it must first be divided into nodes or sections for detailed review. Usually, these nodes include a certain section of piping, valves, and equipment. Visit our website now! https://www.saltegra.com/0 Yorumlar 0 hisse senetleri 426 Views 0 önizleme -

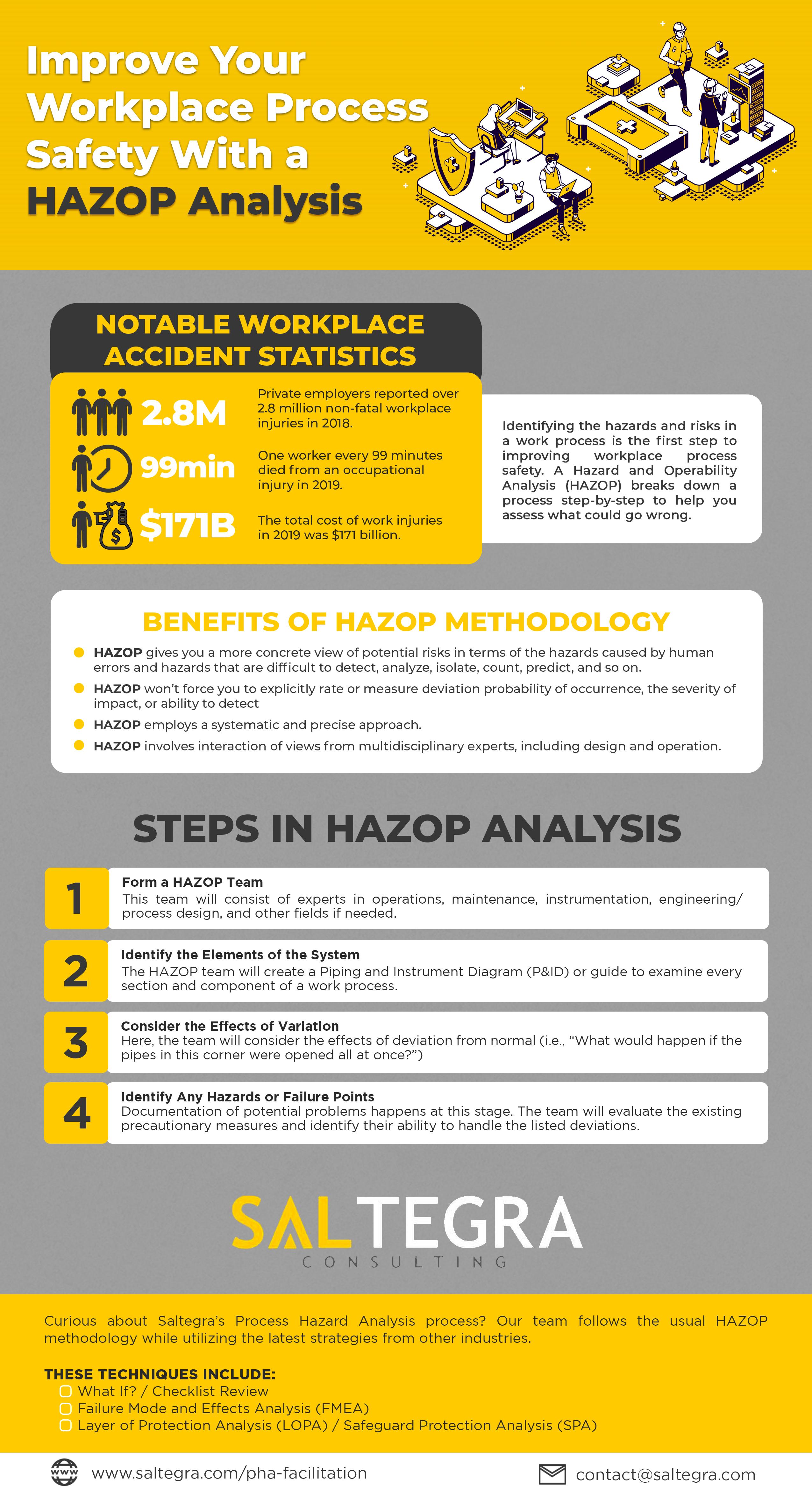

Identifying hazards and risks in a work process is the first step to improving workplace process safety. A Hazard and Operability Analysis (HAZOP) breaks down a process step-by-step to help you assess what you could go wrong.

Secure your workplace process safety today and visit us at https://www.saltegra.com.

#HAZOPAnalysis

#TheSaltegraWay

#SaltegraConsultingLLCIdentifying hazards and risks in a work process is the first step to improving workplace process safety. A Hazard and Operability Analysis (HAZOP) breaks down a process step-by-step to help you assess what you could go wrong. Secure your workplace process safety today and visit us at https://www.saltegra.com. #HAZOPAnalysis #TheSaltegraWay #SaltegraConsultingLLC0 Yorumlar 0 hisse senetleri 510 Views 0 önizleme -

0 Yorumlar 0 hisse senetleri 384 Views 0 önizleme

Daha Hikayeler