-

13 Записей

-

12 Фото

-

0 Видео

-

China Metal Parts Forging OEM Manufacturer Co., Ltd. в Xinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China

-

Проживает в Shanghai

-

Из Jinshan

-

Образование China Forged Metal Parts Manufacturer Provides Prcision Hot, Drop, Closed Die Forging OEM Services, Especially in Custom Carbon, Alloy Steel Components. в

-

04/03/1997

-

Читают 0 человек

Недавние обновления

-

Connecting Rod,Con-rod,Engine Part,Forged Connecting rod. Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрDetail Information

Structure and function of connecting rod.

It is composed of three parts: big end of connecting rod,rod body and small end.Big end is separated, half of which is integrated with the rod body, and the other half is rod cap. Connecting rod cap is assembled with the main crankshaft journal by bolts and nuts.

Connecting rod connects the piston and the crankshaft, and transmits the force exerted by the piston to the crankshaft, transforming the reciprocating motion of the piston into the rotational motion of the crankshaft. It is one of the main transmission components of automotive engines, which transmits the pressure of the expanding gas of the piston to the crankshaft, transforming the reciprocating linear motion of the piston into the rotational motion of the crankshaft, in order to output power.

Raw Material and Forging.

Connecting rod materials are mostly made of high-strength SAE1045 carbon steel, ASTM5140/40Cr carbon steel, etc., through quenching and tempering treatment to improve cutting performance and impact resistance. The hardness requirements for SAE1045 carbon steel are HB217-293 and ASTM5140/40Cr is HB223-280.

Blank of connecting rods is generally produced by forging, and there are two forms of blank: one is the separate forging of the body and cap; Another method is to forge the body and cap integrated, and then cut apart when machining or use an expansion process to break them during the processing. In addition, to avoid defects of the blank, 100% hardness measurement and flaw detection are required.

China Metal Parts Forging Co., Ltd. is a top custom metal parts producer in China, specializing in the manufacturing of steel and alloy forgings. We export to 15+ countries, delivering superior quality products at competitive costs. Learn more: https://www.creatorcomponents.com/Detail Information Structure and function of connecting rod. It is composed of three parts: big end of connecting rod,rod body and small end.Big end is separated, half of which is integrated with the rod body, and the other half is rod cap. Connecting rod cap is assembled with the main crankshaft journal by bolts and nuts. Connecting rod connects the piston and the crankshaft, and transmits the force exerted by the piston to the crankshaft, transforming the reciprocating motion of the piston into the rotational motion of the crankshaft. It is one of the main transmission components of automotive engines, which transmits the pressure of the expanding gas of the piston to the crankshaft, transforming the reciprocating linear motion of the piston into the rotational motion of the crankshaft, in order to output power. Raw Material and Forging. Connecting rod materials are mostly made of high-strength SAE1045 carbon steel, ASTM5140/40Cr carbon steel, etc., through quenching and tempering treatment to improve cutting performance and impact resistance. The hardness requirements for SAE1045 carbon steel are HB217-293 and ASTM5140/40Cr is HB223-280. Blank of connecting rods is generally produced by forging, and there are two forms of blank: one is the separate forging of the body and cap; Another method is to forge the body and cap integrated, and then cut apart when machining or use an expansion process to break them during the processing. In addition, to avoid defects of the blank, 100% hardness measurement and flaw detection are required. China Metal Parts Forging Co., Ltd. is a top custom metal parts producer in China, specializing in the manufacturing of steel and alloy forgings. We export to 15+ countries, delivering superior quality products at competitive costs. Learn more: https://www.creatorcomponents.com/0 Комментарии 0 Поделились 889 Просмотры 0 предпросмотрВойдите, чтобы отмечать, делиться и комментировать! -

Automobile ball joint, steering knuckles,socket joint,forged joint. Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрIn an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals.

A ball joint consists of a bearing stud and socket enclosed in a casing; all these parts are made of steel.The bearing stud is tapered and threaded, and fits into a tapered hole in the steering knuckle. A protective encasing prevents dirt from getting into the joint assembly. Usually, this is a rubber-like boot that allows movement and expansion of lubricant. Motion-control ball joints tend to be retained with an internal spring, which helps to prevent vibration problems in the linkage.

The "offset" ball joint provides means of movement in systems where thermal expansion and contraction, shock, seismic motion, and torsional motions, and forces are present.

On modern vehicles, joints are the pivot between the wheels and the suspension of an automobile. They are today almost universally used in the front suspension, having replaced the kingpin/link pin or kingpin/trunnion arrangement, but can also be found in the rear suspension of a few higher-performance autos. Ball joints play a critical role in the safe operation of an automobile's steering and suspension.

China Metal Parts Forging Co., Ltd. is a leading custom metal parts manufacturer in China, specializing in steel and alloy forgings. We export to over 15 countries, providing high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/In an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals. A ball joint consists of a bearing stud and socket enclosed in a casing; all these parts are made of steel.The bearing stud is tapered and threaded, and fits into a tapered hole in the steering knuckle. A protective encasing prevents dirt from getting into the joint assembly. Usually, this is a rubber-like boot that allows movement and expansion of lubricant. Motion-control ball joints tend to be retained with an internal spring, which helps to prevent vibration problems in the linkage. The "offset" ball joint provides means of movement in systems where thermal expansion and contraction, shock, seismic motion, and torsional motions, and forces are present. On modern vehicles, joints are the pivot between the wheels and the suspension of an automobile. They are today almost universally used in the front suspension, having replaced the kingpin/link pin or kingpin/trunnion arrangement, but can also be found in the rear suspension of a few higher-performance autos. Ball joints play a critical role in the safe operation of an automobile's steering and suspension. China Metal Parts Forging Co., Ltd. is a leading custom metal parts manufacturer in China, specializing in steel and alloy forgings. We export to over 15 countries, providing high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/0 Комментарии 0 Поделились 1Кб Просмотры 0 предпросмотр -

Automobile ball joint, steering knuckles,socket joint,forged joint. Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрIn an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals.

A ball joint consists of a bearing stud and socket enclosed in a casing; all these parts are made of steel.The bearing stud is tapered and threaded, and fits into a tapered hole in the steering knuckle. A protective encasing prevents dirt from getting into the joint assembly. Usually, this is a rubber-like boot that allows movement and expansion of lubricant. Motion-control ball joints tend to be retained with an internal spring, which helps to prevent vibration problems in the linkage.

The "offset" ball joint provides means of movement in systems where thermal expansion and contraction, shock, seismic motion, and torsional motions, and forces are present.

On modern vehicles, joints are the pivot between the wheels and the suspension of an automobile. They are today almost universally used in the front suspension, having replaced the kingpin/link pin or kingpin/trunnion arrangement, but can also be found in the rear suspension of a few higher-performance autos. Ball joints play a critical role in the safe operation of an automobile's steering and suspension.

China Metal Parts Forging Co., Ltd. is a leading custom metal parts manufacturer in China, specializing in steel and alloy forgings. We export to over 15 countries, providing high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/In an automobile, ball joints are spherical bearings that connect the control arms to the steering knuckles, and are used on virtually every automobile made. They bionically resemble the ball-and-socket joints found in most tetrapod animals. A ball joint consists of a bearing stud and socket enclosed in a casing; all these parts are made of steel.The bearing stud is tapered and threaded, and fits into a tapered hole in the steering knuckle. A protective encasing prevents dirt from getting into the joint assembly. Usually, this is a rubber-like boot that allows movement and expansion of lubricant. Motion-control ball joints tend to be retained with an internal spring, which helps to prevent vibration problems in the linkage. The "offset" ball joint provides means of movement in systems where thermal expansion and contraction, shock, seismic motion, and torsional motions, and forces are present. On modern vehicles, joints are the pivot between the wheels and the suspension of an automobile. They are today almost universally used in the front suspension, having replaced the kingpin/link pin or kingpin/trunnion arrangement, but can also be found in the rear suspension of a few higher-performance autos. Ball joints play a critical role in the safe operation of an automobile's steering and suspension. China Metal Parts Forging Co., Ltd. is a leading custom metal parts manufacturer in China, specializing in steel and alloy forgings. We export to over 15 countries, providing high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/0 Комментарии 0 Поделились 966 Просмотры 0 предпросмотр -

Crankshaft forging Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрDetail Information

Advantages of Forged crankshaft

1、 High strength

Forged crankshaft is a high-strength component that needs to withstand the high pressure and high speed generated by vehicle engines. This high strength is due to the fact that the forged crankshaft undergoes multiple heat treatments and thermal deformation processes during the manufacturing process, resulting in refined grain size, improved mechanical properties, and better durability.

2、 Fatigue resistance

Forged crankshaft has certain elasticity and crack resistance, and is not easily broken during long-term high-speed rotation. Therefore, forged crankshafts have excellent wear resistance and durability in high frequency and high speed working environments.

3、 Wear resistance

Forged crankshafts are usually made of high-strength alloy steel, and their surfaces are usually processed by heat treatment, hardening treatment, and other processing methods to improve their wear resistance. This wear resistance can effectively reduce crankshaft wear during prolonged high-speed rotation, while also enabling the vehicle to better adapt to various working environments.

China Metal Parts Forging Co., Ltd. is a premier Chinese manufacturer of custom metal parts, with a focus on steel and alloy forgings. We export to more than 15 countries, providing superior quality at competitive rates. Learn more: https://www.creatorcomponents.com/Detail Information Advantages of Forged crankshaft 1、 High strength Forged crankshaft is a high-strength component that needs to withstand the high pressure and high speed generated by vehicle engines. This high strength is due to the fact that the forged crankshaft undergoes multiple heat treatments and thermal deformation processes during the manufacturing process, resulting in refined grain size, improved mechanical properties, and better durability. 2、 Fatigue resistance Forged crankshaft has certain elasticity and crack resistance, and is not easily broken during long-term high-speed rotation. Therefore, forged crankshafts have excellent wear resistance and durability in high frequency and high speed working environments. 3、 Wear resistance Forged crankshafts are usually made of high-strength alloy steel, and their surfaces are usually processed by heat treatment, hardening treatment, and other processing methods to improve their wear resistance. This wear resistance can effectively reduce crankshaft wear during prolonged high-speed rotation, while also enabling the vehicle to better adapt to various working environments. China Metal Parts Forging Co., Ltd. is a premier Chinese manufacturer of custom metal parts, with a focus on steel and alloy forgings. We export to more than 15 countries, providing superior quality at competitive rates. Learn more: https://www.creatorcomponents.com/0 Комментарии 0 Поделились 720 Просмотры 0 предпросмотр -

Clutch Fork Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрDetail Information

Shift fork on the car gearbox, connected to the gear lever and located at the lower end of the lever, moves the middle gear wheel to change the input/output speed ratio.

If the shift fork on the machine tool is used for variable speed, it is mainly used in the control mechanism

It is to move the two engaged gears apart and then move one of the gears that can slide on the shaft to the other gear to obtain another speed. Namely, changing the position of the sliding gear on the lathe to achieve variable speed.

Alternatively, it can be applied in mechanisms that control the engagement and disengagement of clutches, thereby controlling lateral or longitudinal feed.

China Metal Parts Forging Co., Ltd. is a top custom metal parts producer in China, specializing in the production of steel and alloy forgings. We export to 15+ countries, offering high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/Detail Information Shift fork on the car gearbox, connected to the gear lever and located at the lower end of the lever, moves the middle gear wheel to change the input/output speed ratio. If the shift fork on the machine tool is used for variable speed, it is mainly used in the control mechanism It is to move the two engaged gears apart and then move one of the gears that can slide on the shaft to the other gear to obtain another speed. Namely, changing the position of the sliding gear on the lathe to achieve variable speed. Alternatively, it can be applied in mechanisms that control the engagement and disengagement of clutches, thereby controlling lateral or longitudinal feed. China Metal Parts Forging Co., Ltd. is a top custom metal parts producer in China, specializing in the production of steel and alloy forgings. We export to 15+ countries, offering high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/0 Комментарии 0 Поделились 734 Просмотры 0 предпросмотр -

Control arm forging Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрA control arm is a suspension component that connects the frame of a vehicle to the steering knuckle, which holds the wheel and tire. The control arm allows the wheel and tire to move up and down as the vehicle goes over bumps and uneven road surfaces while maintaining the alignment of the wheel.

The control arm typically consists of two main parts: a ball joint and a bushing. The ball joint connects the control arm to the steering knuckle and allows the wheel to move in different directions, such as when turning. The bushing connects the control arm to the frame and helps to absorb vibrations and shocks from the road, reducing the transfer of these vibrations to the rest of the vehicle. This helps to improve the overall ride comfort and reduce noise and harshness inside the vehicle.

Control arms play a crucial role in the suspension system of a vehicle. They help to keep the wheels aligned and maintain proper tire contact with the road, which is essential for safety and stability. They also help to improve the ride comfort and handling of the vehicle by reducing the transmission of vibrations and shocks from the road to the rest of the vehicle.

China Metal Parts Forging Co., Ltd. is a leading custom metal parts manufacturer in China, specializing in the manufacturing of steel and alloy forgings. We serve customers in more than 15 countries, delivering high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/A control arm is a suspension component that connects the frame of a vehicle to the steering knuckle, which holds the wheel and tire. The control arm allows the wheel and tire to move up and down as the vehicle goes over bumps and uneven road surfaces while maintaining the alignment of the wheel. The control arm typically consists of two main parts: a ball joint and a bushing. The ball joint connects the control arm to the steering knuckle and allows the wheel to move in different directions, such as when turning. The bushing connects the control arm to the frame and helps to absorb vibrations and shocks from the road, reducing the transfer of these vibrations to the rest of the vehicle. This helps to improve the overall ride comfort and reduce noise and harshness inside the vehicle. Control arms play a crucial role in the suspension system of a vehicle. They help to keep the wheels aligned and maintain proper tire contact with the road, which is essential for safety and stability. They also help to improve the ride comfort and handling of the vehicle by reducing the transmission of vibrations and shocks from the road to the rest of the vehicle. China Metal Parts Forging Co., Ltd. is a leading custom metal parts manufacturer in China, specializing in the manufacturing of steel and alloy forgings. We serve customers in more than 15 countries, delivering high-quality products at competitive prices. Learn more: https://www.creatorcomponents.com/0 Комментарии 0 Поделились 651 Просмотры 0 предпросмотр -

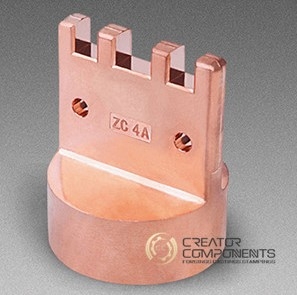

Customized Copper Machined Forging Part Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрDetail Information

Name: Copper Machined Forging Part.

Type: Copper Alloy Forging.

Materials: Copper Alloy.

Process: Forging Process.

Surface Treatment: Annealing Treatment.

Certificate: ISO, RoHS, TUV.

Heat Treatment: Normalizing Annealing, Solution, Passivation.

Advantages: Strict Quality Control System, Competitive Price, 100% Inspection.

Inspection: Third Party Inspection is Available According to Your Requirement.

Export Markets: North America, South America, Eastern Europe, Africa, Mid East, Western Europe.

China Metal Parts Forging Co., Ltd. is a prominent custom metal parts maker, focused on steel and alloy forgings. With exports to 15+ countries, we provide top quality at competitive rates. Visit: https://www.creatorcomponents.com.Detail Information Name: Copper Machined Forging Part. Type: Copper Alloy Forging. Materials: Copper Alloy. Process: Forging Process. Surface Treatment: Annealing Treatment. Certificate: ISO, RoHS, TUV. Heat Treatment: Normalizing Annealing, Solution, Passivation. Advantages: Strict Quality Control System, Competitive Price, 100% Inspection. Inspection: Third Party Inspection is Available According to Your Requirement. Export Markets: North America, South America, Eastern Europe, Africa, Mid East, Western Europe. China Metal Parts Forging Co., Ltd. is a prominent custom metal parts maker, focused on steel and alloy forgings. With exports to 15+ countries, we provide top quality at competitive rates. Visit: https://www.creatorcomponents.com.0 Комментарии 0 Поделились 679 Просмотры 0 предпросмотр -

Customized Aluminum Forged Wear Part Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрDetail Information

Name: Customized Aluminum Forged Wear Part.

Type: Aluminum Alloy Forging.

Materials: Aluminum Alloy.

Process: Forging Process.

Surface Treatment: Sandblasting, Tumbling.

Certificate: TUV, CMM, ISO.

Inspection: Third Party Inspectionis Available.

Features:

Wear Resistant, Corrosion Resistant, Accurate Dimension, Sturdy Construction.

Means of Transportation: Ocean Transportation, Rail Transportation, Air Transportaion, Combined Transportation.

China Metal Parts Forging Co., Ltd. specializes in custom metal parts, with expertise in steel and alloy forgings. Exporting to 15+ nations, we ensure superior quality and competitive pricing. Learn more: https://www.creatorcomponents.com.Detail Information Name: Customized Aluminum Forged Wear Part. Type: Aluminum Alloy Forging. Materials: Aluminum Alloy. Process: Forging Process. Surface Treatment: Sandblasting, Tumbling. Certificate: TUV, CMM, ISO. Inspection: Third Party Inspectionis Available. Features: Wear Resistant, Corrosion Resistant, Accurate Dimension, Sturdy Construction. Means of Transportation: Ocean Transportation, Rail Transportation, Air Transportaion, Combined Transportation. China Metal Parts Forging Co., Ltd. specializes in custom metal parts, with expertise in steel and alloy forgings. Exporting to 15+ nations, we ensure superior quality and competitive pricing. Learn more: https://www.creatorcomponents.com.0 Комментарии 0 Поделились 671 Просмотры 0 предпросмотр -

OEM Door Hinges.Customized forging.Forged Door Hinge Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрForged hinge is a mechanical device used to connect two solids and allow relative rotation between them. The hinge can be composed of movable components or foldable forged items.

Forged hinges have high strength, good toughness, and are less possible breakage when collisions, providing a better connection between the car door and the car body.

The national standard for hinges requires that the door hinge can withstand a longitudinal load of 11.11KN and a transverse load of 8.89KN without detachment.

Gernerally,the raw material for forged hinges should be have good welding properties like Q355B.

Forged hinge production process.

Raw material lab testing Material cutting Medium frequency heating Forging by pneumatic hammer Advance shape forging Final shape forging Trimming forging Hot bending Hot correcting Shot blasting Flash and burr cleansing Shot blasting Logo marking by pneumatic Forging checking Cleansing and antirust Packaging.

China Metal Parts Forging Co., Ltd. is a trusted manufacturer of custom metal parts, with a focus on steel and alloy forgings. Serving over 15 countries, we offer top-notch quality at competitive prices. Explore: https://www.creatorcomponents.com.Forged hinge is a mechanical device used to connect two solids and allow relative rotation between them. The hinge can be composed of movable components or foldable forged items. Forged hinges have high strength, good toughness, and are less possible breakage when collisions, providing a better connection between the car door and the car body. The national standard for hinges requires that the door hinge can withstand a longitudinal load of 11.11KN and a transverse load of 8.89KN without detachment. Gernerally,the raw material for forged hinges should be have good welding properties like Q355B. Forged hinge production process. Raw material lab testing Material cutting Medium frequency heating Forging by pneumatic hammer Advance shape forging Final shape forging Trimming forging Hot bending Hot correcting Shot blasting Flash and burr cleansing Shot blasting Logo marking by pneumatic Forging checking Cleansing and antirust Packaging. China Metal Parts Forging Co., Ltd. is a trusted manufacturer of custom metal parts, with a focus on steel and alloy forgings. Serving over 15 countries, we offer top-notch quality at competitive prices. Explore: https://www.creatorcomponents.com.0 Комментарии 0 Поделились 832 Просмотры 0 предпросмотр -

Spindle forging for RV Новое$12В наличииXinta Industrial Zone, Xinggui Road, Fengjing, Jinshan, Shanghai, China0 предпросмотрDetail Information

Forging materials:ASTM1035,ASTM1045,ASTM1021,ASTM1040,ASTM1320/20Mn2,ASTM1340/40Mn2,ASTM5120/20Cr,ASTM5140/40Cr,ASTM4119/20CrMo,ASTM4140/42CrMo,ASTM4135/35CrMo,ASTM4340/40CrNiMo,ST52-3/Q355/16Mn

Forging Method:Closed die forging,Warm forging,Roll ring forging.

OEM No:Customized

Weight:1-100KGS

Dimension:Customized

Certificates:ISO/TS16949

Heat treatment:Normalizing,Quenching and tempering

Test:Magnetic Powder Defects Test, Hardness Test, Dimension Test

China Metal Parts Forging Co., Ltd. is a top custom metal parts producer, specializing in steel and alloy forgings. We export to 15+ countries, delivering high-quality products at competitive costs. Visit: https://www.creatorcomponents.com.Detail Information Forging materials:ASTM1035,ASTM1045,ASTM1021,ASTM1040,ASTM1320/20Mn2,ASTM1340/40Mn2,ASTM5120/20Cr,ASTM5140/40Cr,ASTM4119/20CrMo,ASTM4140/42CrMo,ASTM4135/35CrMo,ASTM4340/40CrNiMo,ST52-3/Q355/16Mn Forging Method:Closed die forging,Warm forging,Roll ring forging. OEM No:Customized Weight:1-100KGS Dimension:Customized Certificates:ISO/TS16949 Heat treatment:Normalizing,Quenching and tempering Test:Magnetic Powder Defects Test, Hardness Test, Dimension Test China Metal Parts Forging Co., Ltd. is a top custom metal parts producer, specializing in steel and alloy forgings. We export to 15+ countries, delivering high-quality products at competitive costs. Visit: https://www.creatorcomponents.com.0 Комментарии 0 Поделились 507 Просмотры 0 предпросмотр

Больше