Incorporating Seaweeds as a healthy alternative to formulate low-salt meat products |Foodresearchlab

Meat products or processed meat are generally considered unhealthy due to the main source of sodium exceeding 30 % of the total daily intake in most diets. Salt is incorporated as a multi-functional ingredient, such as preventing spoilage, conferring flavour and obtaining desired texture. Moreover, they are used excessively due to their low cost. Such excessive consumption of salt is linked with an increased risk of hypertension and cardiovascular diseases. For adults, the recommended intake limit of salt is less than 5 g per day was given by the World Health Organization (WHO). Therefore, formulating a new low salt meat product with stable physio-chemical, microbial and sensory properties are ideal. Various strategies have been used in the past, for substitution of sodium chloride with calcium, potassium and magnesium salts and even a mix of these. However, due to their metallic bitter after taste and negative impacts on the nutrition profile they are not accepted by consumers.

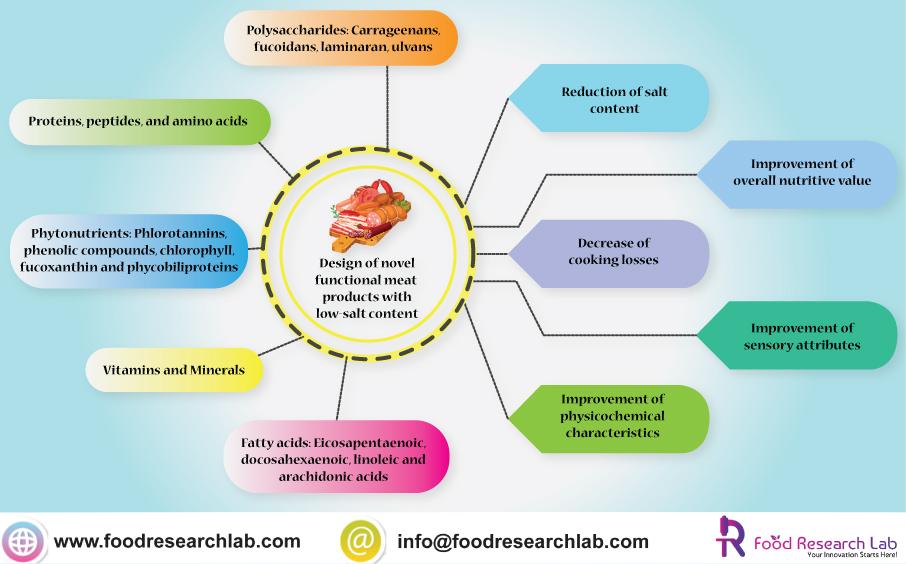

Foods enriched with edible seaweeds or seaweeds extractions offer novel opportunities to develop healthier foods to formulate low salt and low-fat meat products with less calories, and less saturated fatty acids. Seaweeds are rich source bio-nutrients like polysaccharides, PUFA, proteins, and vitamins and minerals. The high mineral content in the seaweeds offers the opportunity as a functional replacer, due to their low Na/K ratio, in processed meat with low salt and energy values and with reduced risk of health conditions.

Application of seaweeds in meat products

Different ingredients have been tested to be used as a salt substitute, such as AlgySalt, PureSea in different processed meats. These ingredients provide organoleptic and technological characteristics for the final product formulation with little or no salt content. An experiment conducted comparing the salts from different sources, such as NaCl, KCl, CaCl2, MgCl2 and AlgySalt in fresh and cooked sausages. Final characteristics such as microbial stability, sensory and technological characteristics were studied. It was found that seaweed, AlgySalt showcased, good binding properties, greater hardness with little cooking losses compared to the other salts tested. In terms of microbial stability, seaweed has similar microbial resistance with chemical salts. Unprocessed meat products formulated with AlgySalt showcased significant better colour, texture, and had a juicier texture. On the other hand, cooked meat products with salt had a better sensory customer acceptance.

In a similar experiment, where the frankfurter sausages were evaluated, the addition of seaweed aided in reducing the cooking loss, colour, texture profile and sensory profiles were improved. When compared with seaweed varieties, sea tangle and sea mustard presented the best results in terms of emulsion stability, cooking loss and retention of sensory properties. The textural properties such as cohesiveness, springiness and exterior hardness were found to be unchanged when sea mustard was used in the emulsion-based meat products. It was also recorded that the reformulated meat emulsion had higher viscosity with improved elasticity. This is considered a valuable quality indicator for emulsion meat products.

Water soluble extract from Palmaria palmate was found to be an effective salt replacer to be used in cooked ham. This application did not affect the final yield, colour, texture of the final product. This application yielded almost 6 months of refrigerated storage period. Similarly, incorporation of Wakame in black puddings resulted in an unaltered change in colour and appearance and lower cooking loss was observed. Black pudding with 0.6% NaCl and seaweed application yielded higher spiciness and saltiness scores compared to the control. Edible algae such as Porphyra umbilicalis, P. palmate, Himanthalia elongata and Undaria pinnatifida, when used in the preparation of sausages improved the customer acceptance by 50%. The results revealed that these algae lowered the lightness (L*), redness (a*) and yellowness (b*) values in comparison to the control sample. Due to the presence of the polysaccharides from the seaweeds, dark compounds are formed in pork meat during the Maillard stage of the cooking process.

| Food product | Seaweed application | Results |

| Sausage | 2% AlgySalt | Decreased cooking loss Increased texture hardness Microbial stability up to 15 days at 4℃ |

| Frankfurters | 1% of Sea mustard Sea tangle Hijiki Glasswort | Drop in moisture levels, salinity and cooking loss. Colour, redness, gumminess and chew ability were found to have decreased. |

| Frankfurters | 1% of Porphyra umbilicalis, Palmaria palmate, Himanthalia elongata Undaria pinnatifida | 50 % reduction in salt content Lowered L*, a* and b* values Hardness and chewiness were reduced. Sensory acceptance was much lower |

| Meat emulsion | 2% Sea mustard | 20% reduction in salt content Increased viscosity Microbial stability was found at 4℃ |

| Cooked ham | Palmaria palmata | No cooking loss No change in texture and final colour 30% reduction of salt content Microbial stability up to 6 months at 4℃. |

| Black pudding | 3.3% Wakame | Lowered cooking loss No change in appearance and final colour was similar to control Microbial stability was found at 4℃ |

| Chicken meat | 0.4% Eucheuma spinosum | Water holding capacity was improved Microbial stability was found at 4℃ |

Numerous research projects have demonstrated improved shelf-life when seaweed has been used as an ingredient in the likes of processed meat and bread. A review conducted by researchers reported that sausages that contained Ascophyllum nodosum seaweed species had a lower population of lactic acid bacteria (LAB) over time (Figure 1), as well as lower bacterial counts such as the Total Viable Count (TVC) and coliform in comparison to the control sausage

Furthermore, when A. nodosum was used in preservative-free bread, it extended the shelf-life (reducing mould growth) by as much as 9 days in comparison to the preservative-free control that contained 5g of salt (sodium chloride) (Figure 3).

Additional benefits of seaweed from another study conducted by Sheffield Hallam University, investigated the acceptability of seaweed (A. nodosum) enriched breadxiv. They concluded that bread enriched with seaweed, not only improved the fibre content, but also allowed for additional health benefits that are associated with A. nodosum. Most importantly, they found that 79 untrained sensory panellists who assessed the various samples (in the form of toast with scrambled egg) for appearance, flavour, aroma, aftertaste, and texture, found that up to 20g per 400g loaf of seaweed was acceptable (with a score similar to that of the control). This led them to conclude that “seaweed presents an attractive option for food manufacturers who are keen to maximise the health-giving potential of their dietary fibre-rich products”

Summary

Seaweeds have been historically consumed in Asia for nutrition and therapeutic purposes. In recent times, western countries are adapting to it for the purposes of recovery of hydrocolloids; such as alginate, agar and carrageenan in the food industry. The inclusion of seaweeds as a functional replacer in meat based products was found to be a promising and healthier alternative when compared to salted meats. In terms of business, the demand for seaweeds is growing exponentially for food and pharmaceutical sectors which are expected to reach USD 22 billion by 2024.

A few challenges were identified in selecting the correct variety of seaweeds and their appropriate method of incorporation. Continuous trial and error experiments were conducted to identify the appropriate type and dosage with improved customer acceptance. It was also clearly evaluated that the impact of including seaweeds on nutritional, physio-chemical, microbial properties of the reformulated meat product had improved substantially.

Food Research Lab can help you solve these problems with related to formulation of low fat and low salt meat products. FRL is for food and nutraceutical manufacturers as well as those companies involved in NPD and developing spec without manufacturing. FRL gives you the ability to improve all phases and aspects of new product development, such as original specification, ideation, shelf-life, packaging. Additionally, you can get them out to market quicker than ever before.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News