Electric Vehicle Battery Adhesive Market: Market Winning Strategies for Growth and Innovation

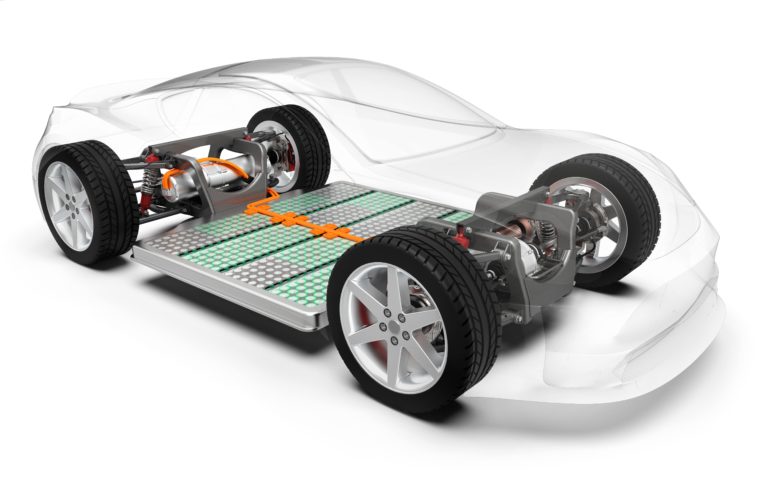

The electric vehicle battery adhesive market is witnessing substantial growth, driven by the increasing demand for electric vehicles (EVs) and the need for specialized solutions in battery pack design and manufacturing. Adhesives play a crucial role in ensuring battery stability, thermal management, and electrical insulation, all of which are essential for EV battery performance and safety. As the EV industry continues to evolve, companies in the electric vehicle battery adhesive market must employ effective strategies to remain competitive and capture market share. Below are the key market-winning strategies that companies can adopt to thrive in this dynamic industry.

1. Focus on Product Innovation

To meet the increasing demands of EV battery applications, companies must continuously invest in research and development to create next-generation adhesive solutions. Innovations in adhesive properties, such as enhanced thermal conductivity, chemical resistance, and flexibility, will allow companies to meet the evolving needs of the electric vehicle battery adhesive market. Adopting cutting-edge technologies like nanomaterials or incorporating eco-friendly formulations into adhesive products can give manufacturers a competitive edge. This strategy not only positions companies as industry leaders but also helps address the increasing emphasis on sustainability in the automotive sector.

2. Strengthen Strategic Partnerships

Forming strategic partnerships with key players in the EV supply chain, including automakers, battery manufacturers, and raw material suppliers, is a critical strategy in the electric vehicle battery adhesive market. These collaborations facilitate the development of customized adhesive solutions that align with specific needs, such as improved heat management or fire resistance. By working closely with battery manufacturers, adhesive suppliers can ensure their products meet the strict performance and safety requirements essential for EV battery systems. Additionally, such partnerships help manufacturers gain access to new markets and leverage resources for joint marketing, increasing their reach and impact in the competitive market.

3. Expand Geographic Reach

The electric vehicle market is experiencing rapid growth in several regions, including Asia-Pacific, Europe, and North America. Companies operating in the electric vehicle battery adhesive market should look to expand their geographic presence, targeting high-growth regions where EV adoption is accelerating. In particular, Asia-Pacific represents a lucrative market due to the region’s dominance in EV production, especially in countries like China, Japan, and South Korea. By establishing a foothold in these regions, companies can tap into a growing customer base and position themselves as key suppliers in these emerging markets.

4. Offer Sustainable and Eco-Friendly Solutions

Sustainability is becoming a central theme in the automotive industry, with automakers seeking to reduce their environmental impact. To align with this shift, manufacturers in the electric vehicle battery adhesive market must prioritize the development of eco-friendly adhesives. These adhesives can be made from renewable resources, have low volatile organic compound (VOC) emissions, or be fully recyclable. By offering green alternatives, adhesive manufacturers can not only meet the regulatory standards set by governments but also attract environmentally conscious consumers and businesses. This strategy can significantly improve a company’s reputation in the market, offering long-term growth opportunities.

5. Optimize Cost-Effectiveness

While high-performance adhesives are crucial for EV battery applications, the cost remains a significant factor in the overall affordability of electric vehicles. Companies in the electric vehicle battery adhesive market should focus on developing cost-effective solutions without compromising performance. One approach is to improve manufacturing processes to reduce production costs, such as automation or sourcing raw materials more efficiently. Companies can also explore alternative adhesive materials that maintain performance but are more affordable. This cost-conscious approach allows manufacturers to offer competitive pricing, making it easier for automakers to incorporate advanced adhesives into their EV designs without driving up vehicle prices.

6. Enhance Customer Education and Support

An effective strategy for market expansion involves educating customers on the benefits and applications of battery adhesives. Companies can provide educational resources, webinars, and workshops to help OEMs (Original Equipment Manufacturers) and battery manufacturers understand the advantages of using advanced adhesives in EV battery packs. Offering strong customer support and after-sales services ensures that customers are confident in their adhesive choices and can achieve optimal performance in their EV battery systems. By positioning themselves as trusted partners, adhesive manufacturers can build long-term relationships with their clients, which can lead to repeated business and greater customer loyalty.

7. Leverage Digital Marketing and E-Commerce

As digital transformation continues to shape industries, adhesive manufacturers must adopt robust digital marketing strategies to reach a wider audience. Establishing a strong online presence through targeted advertisements, content marketing, and social media can increase brand visibility and drive customer engagement. Additionally, the rise of e-commerce platforms has created new opportunities for adhesive manufacturers to sell directly to customers, reducing reliance on traditional distribution channels. By leveraging digital tools, companies can connect with potential customers globally, making it easier to introduce new products and offer support services.

8. Maintain Strong Compliance with Regulations

With the increasing emphasis on safety and environmental standards in the automotive industry, companies in the electric vehicle battery adhesive market must ensure that their products comply with all relevant regulations. These may include fire resistance standards, safety certifications, and environmental impact assessments. By proactively addressing regulatory requirements, adhesive manufacturers can avoid compliance issues that could hinder market access or lead to costly recalls. Staying ahead of regulatory trends, especially in global markets, ensures that products are market-ready and meet consumer expectations for safety and sustainability.

9. Diversify Product Portfolio

To mitigate risks associated with market fluctuations and technological changes, companies should diversify their product offerings. By offering a wide range of adhesives suited for different EV battery applications, manufacturers can cater to various customer needs and expand their market share. This diversification could include developing adhesives for different battery chemistries or for new electric vehicle types such as commercial vehicles or buses. A broad product portfolio enables companies to stay resilient against industry changes and capitalize on emerging trends.

Conclusion

The electric vehicle battery adhesive market is evolving rapidly, and companies must implement well-rounded strategies to stay competitive. By focusing on product innovation, forming strategic partnerships, expanding geographic reach, and promoting sustainability, companies can capitalize on the growth of the EV industry. Additionally, enhancing cost-effectiveness, offering educational support, leveraging digital platforms, and complying with regulations will help companies secure long-term success in this promising market.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News