From Design to Delivery: A Guide to Custom Metal Molds

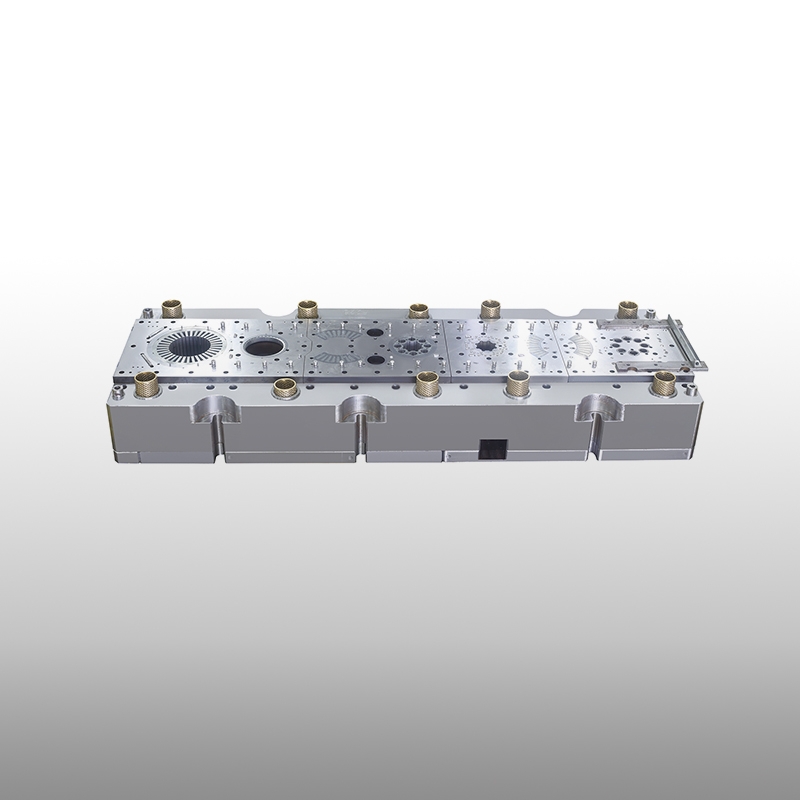

The initial step in the process of creating a custom metal mold is the design phase. This involves a detailed analysis of the part requirements, including dimensions, tolerances, material properties, and production volume. The design must take into account the manufacturing process that will be used, such as injection molding, die casting, or forging. It is crucial to work closely with engineers and designers to ensure that the mold design is feasible and can produce the desired results. Utilizing advanced CAD software can help in creating accurate 3D models of the mold, allowing for simulations and optimizations before the fabrication begins.

Rechercher

Commandité

Catégories

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News

Lire la suite

Invisalign Can Be Chosen By Infants And Seniors Too

Although there is no upper age limit for wearing Invisalign in Baltimore, it is ideal for kids to...

Pass Guaranteed 2023 CyberArk Latest PAM-SEN: CyberArk Sentry - PAM Valid Dumps Book

DOWNLOAD the newest Exams4sures PAM-SEN PDF dumps from Cloud Storage for free:...

Ultrafiltration Market, Revenue Growth Trends, Company Strategy Analysis by Fact MR

The global ultrafiltration market stands at US$ 2.96 billion in 2023 and is projected to reach...

Book Writing for Beginners - Consider Using Book Writing Assistants

It will usually take a lot of effort to conclude writing your first BookWritingOnline....

Opacifiers Market Outlook: Growth Factors Details, Trends, Comprehensive Research Including Top Companies

The Opacifiers Market was valued at USD 17.29 billion in 2023. It is projected to grow...