Analyzing Growth Drivers in the Monoethylene Glycol Market

The monoethylene glycol market is witnessing robust growth, supported by various industry trends and factors that contribute to its rising demand. As a key ingredient in the production of polyester fibers, antifreeze, and polyethylene terephthalate (PET) resins, monoethylene glycol plays a critical role in several sectors. This article examines the primary growth drivers fueling the expansion of the monoethylene glycol market.

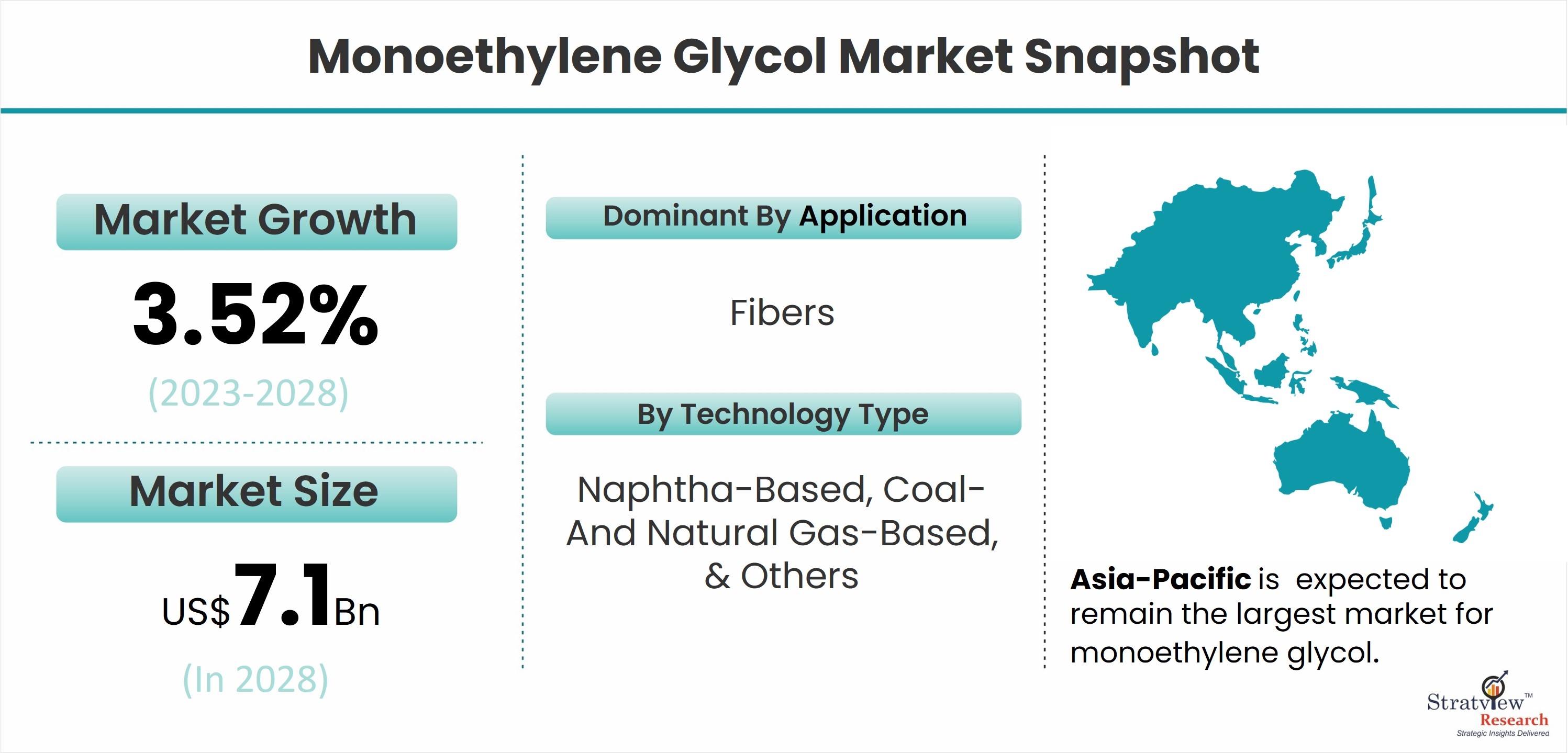

According to Stratview Research, the monoethylene glycol market was estimated at USD 5.77 billion in 2022 and is likely to grow at a CAGR of 3.52% during 2023-2028 to reach USD 7.1 billion in 2028.

1. Increasing Demand in the Textile Sector

One of the most significant drivers of monoethylene glycol demand is its essential role in the textile industry, particularly in the production of polyester fibers. Polyester, being one of the most widely used synthetic fibers, is favored for its durability, versatility, and cost-effectiveness. The global textile market is expanding, with rising consumer preferences for affordable and high-quality clothing. As demand for polyester fabrics continues to grow, so too does the need for monoethylene glycol, which is a primary feedstock in its production.

2. Expansion of the PET Packaging Industry

The increasing use of polyethylene terephthalate (PET) in packaging applications is another critical factor driving monoethylene glycol market growth. PET is extensively used for manufacturing bottles, containers, and films due to its lightweight nature and recyclability. The growing focus on sustainable packaging solutions and the demand for lightweight materials in the food and beverage sector are propelling the need for PET, thereby enhancing the demand for monoethylene glycol as a key raw material in its production. As consumers and industries alike seek eco-friendly packaging options, the role of monoethylene glycol becomes increasingly vital.

3. Rapid Urbanization and Industrial Growth in Emerging Markets

Emerging markets, particularly in Asia-Pacific, are experiencing rapid urbanization and industrialization, contributing significantly to monoethylene glycol demand. Countries like China and India are witnessing substantial growth in manufacturing, construction, and automotive sectors. This industrial expansion is driving the demand for products that utilize monoethylene glycol, such as antifreeze for vehicles and various consumer goods. The urbanization trend leads to increased consumption of packaged products and textiles, further boosting the monoethylene glycol market.

4. Technological Advancements in Production Processes

Advancements in production technology are also enhancing the growth prospects of the monoethylene glycol market. Innovations in manufacturing processes are leading to more efficient, cost-effective, and environmentally friendly production methods. Companies are increasingly adopting new technologies to reduce energy consumption and waste during monoethylene glycol production, aligning with global sustainability goals. This focus on technological improvements not only lowers production costs but also attracts investment in the monoethylene glycol market.

Conclusion

The growth of the monoethylene glycol market is driven by a confluence of factors, including increasing demand in the textile and PET packaging industries, rapid urbanization and industrialization in emerging markets, and technological advancements in production processes. As these drivers continue to evolve, the monoethylene glycol market is poised for sustained growth, playing a vital role in various industries and applications.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News