Unlocking Precision: The Power of CNC Vertical Machining Centers

In the realm of modern manufacturing, precision is not just a luxury—it's a necessity. CNC (Computer Numerical Control) vertical machining center have become indispensable tools in achieving the high levels of accuracy and efficiency that industries demand today. This blog will delve into what CNC vertical machining centers are, their numerous advantages, various applications, and tips for optimizing their use in your manufacturing processes.

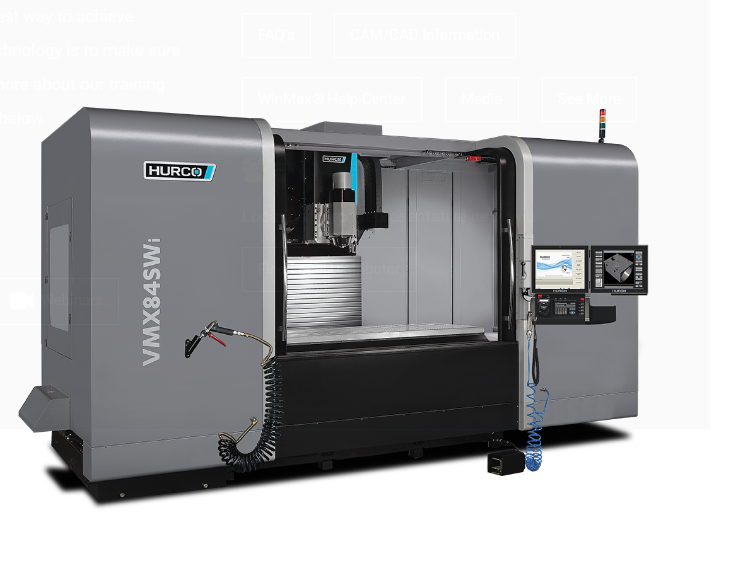

Understanding CNC Vertical Machining Centers

CNC machining center and Vertical machining center advanced machines that automate the machining process through computer programming. Unlike traditional machining, which relies heavily on manual operation, CNC machines use computer systems to control the movement of cutting tools and workpieces. This automation leads to consistent and precise outcomes, making them ideal for a wide range of applications.

These machines feature a vertically oriented spindle that enables efficient cutting and shaping of various materials, including metals, plastics, and composites. The ability to program complex designs makes CNC vertical machining centers particularly valuable in industries that require intricate components.

Key Advantages of CNC Vertical Machining Centers

Unmatched Precision

One of the most significant advantages of CNC vertical machining centers is their ability to deliver exceptional precision. The computer-controlled operations reduce human error, ensuring that every component produced meets strict specifications. This level of accuracy is crucial for industries like aerospace and medical device manufacturing, where even the slightest deviation can lead to critical failures.

Increased Efficiency

CNC machines can run continuously with minimal supervision, significantly enhancing productivity. Once a program is set, these machines can produce identical parts rapidly, streamlining the production process. This efficiency is vital for meeting tight deadlines and high-volume demands.

Versatility in Applications

CNC vertical machining centers are incredibly versatile. They can handle a wide variety of materials and adapt to different production requirements. Whether you're working with aluminum, stainless steel, or high-density plastics, these machines can be configured to achieve the desired results, making them suitable for multiple industries.

Complex Design Capabilities

With CNC technology, manufacturers can create complex shapes and designs that are difficult or impossible to achieve with traditional machining. This capability opens up new avenues for innovation, allowing engineers and designers to push the boundaries of what is possible in product development.

Cost-Effectiveness

Although the initial investment in CNC vertical machining centers can be substantial, they often lead to cost savings in the long run. Reduced waste, fewer errors, and the ability to produce parts quickly contribute to a lower overall cost of production. Additionally, the automation of processes reduces the need for manual labor, allowing businesses to allocate resources more effectively.

Applications of CNC Vertical Machining Centers

CNC vertical machining centers are employed in various industries, showcasing their adaptability and effectiveness. Here are some notable applications:

Aerospace: In this sector, precision is critical. CNC machines are used to manufacture components such as brackets, fittings, and complex structural parts that must meet stringent safety standards.

Automotive: From engine blocks to custom parts, the automotive industry relies on CNC machining for high-quality components that are produced efficiently. This technology allows for rapid prototyping and adaptation to design changes.

Medical Devices: The medical industry demands unparalleled accuracy. CNC vertical machining centers are essential for producing surgical instruments, implants, and other vital components that require strict adherence to specifications.

Electronics: CNC machining is widely used in electronics manufacturing for creating intricate circuit boards, housings, and connectors, ensuring that they meet the necessary performance criteria.

Tips for Mastering CNC Vertical Machining Centers

To fully harness the power of CNC vertical machining centers, consider the following best practices:

Invest in Quality Software

The software you choose to control your CNC machine is crucial. Select high-quality CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software that can seamlessly integrate with your machine. Look for features like tool path optimization and simulation capabilities to ensure efficient machining processes.

Know Your Materials

Understanding the characteristics of the materials you work with is essential for optimizing machining parameters. Different materials may require specific cutting speeds, feeds, and tooling. Conduct material tests to determine the most effective settings for your applications.

Regular Maintenance

Maintaining your CNC machine is vital for its performance and longevity. Create a maintenance schedule that includes regular cleaning, lubrication, and inspection of components. This proactive approach can prevent unexpected breakdowns and keep your machine running smoothly.

Continuous Training

The landscape of CNC machining is constantly evolving. Ensure that your team is well-trained and knowledgeable about the latest technologies and techniques. Consider ongoing education opportunities, such as workshops or online courses, to enhance their skills.

Quality Control Measures

Implement stringent quality control protocols to verify that all produced parts meet specifications. Utilize tools like coordinate measuring machines (CMM) to inspect dimensions and tolerances, ensuring that each component is up to standard.

Leverage Advanced Tooling

Invest in high-quality cutting tools that are appropriate for your specific machining tasks. Advanced tooling can significantly improve performance, reduce wear, and enhance the surface finish of your parts. Consider using tools with specialized coatings for better durability.

Seek Expert Guidance

If you are new to CNC machining, don’t hesitate to seek assistance from experienced professionals. Collaborating with experts can provide valuable insights into best practices and help you optimize your processes for better results.

Conclusion

CNC vertical machining centers are powerful tools that unlock precision and efficiency in modern manufacturing. By understanding their advantages, applications, and best practices, manufacturers can elevate their production capabilities and stay competitive in an ever-evolving market. Embrace the technology, invest in training and quality tools, and watch your manufacturing processes transform from concept to precision-engineered reality. With CNC vertical machining centers, the possibilities are endless!

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News