Personalized Products: The Versatility and Potential of 3D Printing

A Brief Overview of 3D Printing Technology

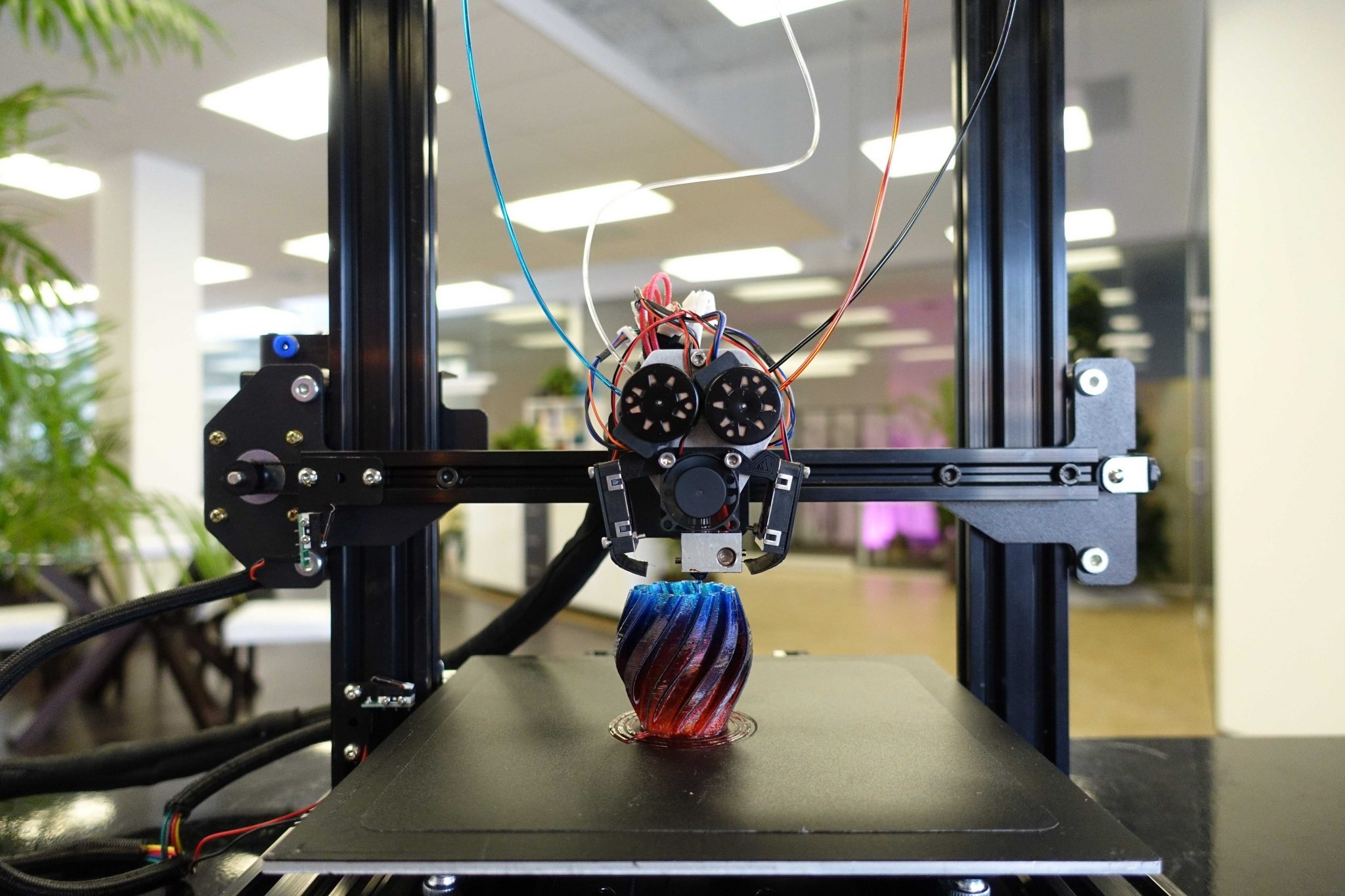

3D printing, also known as additive manufacturing, involves creating physical objects from digital designs by layering materials, such as plastics, metals, or resins, until the final product takes shape. The process starts with designing the object in a CAD (computer-aided design) program. Once the design is complete, the 3D printer reads the digital file and begins printing the object layer by layer.

This method differs from traditional manufacturing processes, which often rely on subtractive techniques like cutting, drilling, or molding materials into the desired shape. The layer-by-layer approach of 3D printing allows for greater precision and the ability to create complex geometries that would be impossible to achieve with conventional methods.

From Prototypes to Personalized Products

The initial appeal of 3D Printing was its ability to create rapid prototypes. Designers and engineers could quickly produce physical models of their digital designs, allowing them to test, iterate, and refine their ideas before committing to large-scale production. This significantly sped up the product development process and reduced costs.

However, as the technology matured, it became clear that 3D printing could do more than just make prototypes—it could create fully functional, personalized products. This shift opened the door to a new era of customization, where products could be tailored to individual needs and preferences.

1. Medical and Healthcare Advancements

One of the most exciting applications of 3D printing is in the field of healthcare. Medical professionals can now create patient-specific implants, prosthetics, and devices that are customized to fit the unique anatomy of each individual. For example, 3D-printed prosthetics are more affordable and can be produced faster than traditional prosthetics, making them accessible to more patients, particularly in developing regions.

In addition, 3D printing is being used to create surgical models that allow doctors to practice complex procedures before operating on a patient. These models, made from scans of the patient’s body, provide a high level of precision and can improve surgical outcomes.

Get more insights on 3D Printing

For Enhanced Understanding, Dive into the Report in the Language that Connects with You

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News