Overmolding is a process that involves combining two different materials to create a single, cohesive product. This technique is widely used in industries such as aerospace, automotive, electronics, and medical devices to enhance the performance and durability of products. One of the key benefits of overmolding is the ability to seamlessly integrate multiple materials, such as thermoplastics, rubber, and metal, into a single component.

The Overmolding Process: Material Selection and Compatibility

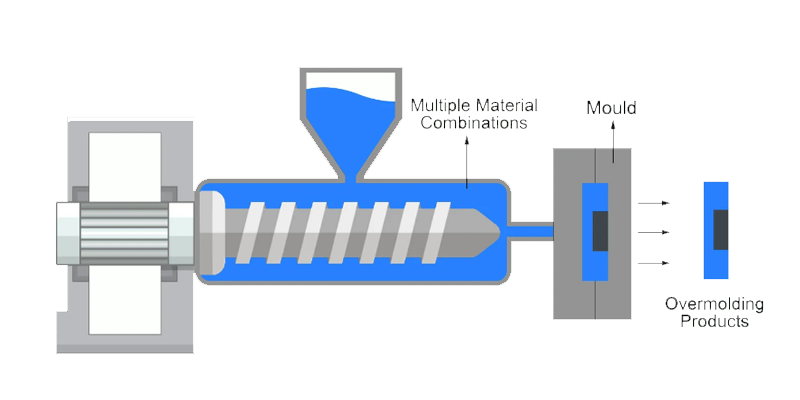

The overmolding process begins with the selection of materials that are compatible with each other and can adhere to one another during the molding process. This is crucial to ensure the strength and durability of the final product. The first material, known as the substrate, serves as the base onto which the second material, known as the overmold, is applied. The substrate material is typically rigid and provides the structural integrity of the component, while the overmold material is flexible and provides additional properties such as improved grip, cushioning, or weather resistance.

Methods of Overmolding: Insert Molding, Two-Shot Molding, and Co-Injection Molding

Efficient overmolding involves precise control over the injection molding process to ensure that the two materials bond together effectively. This requires careful consideration of factors such as material compatibility, injection temperature, pressure, and cooling rate. The overmolding process can be conducted using several methods, including insert molding, two-shot molding, and co-injection molding. Each method has its own advantages and limitations, and the selection of the most appropriate method depends on the specific requirements of the product.

Design and Engineering Considerations for Efficient Overmolding

Efficient overmolding also requires advanced design and engineering capabilities to ensure that the two materials work together seamlessly. This includes optimizing the part geometry, material selection, and tooling design to achieve the desired performance characteristics. By integrating multiple materials strategically, manufacturers can enhance the functionality, aesthetics, and durability of their products.

Benefits of Overmolding: Enhanced Performance, Aesthetics, and Durability

In conclusion, overmolding offers a versatile and efficient way to integrate multiple materials into a single component. By carefully selecting materials, controlling the injection molding process, and optimizing the design, manufacturers can create products that offer superior performance and durability. The seamless integration of multiple materials through overmolding helps to improve the overall quality of the product and enhance its value to customers.