Polypropylene (PP) yarn has gained significant popularity in various industries due to its durability, versatility, and cost-effectiveness. Among the different types of PP yarn, PP fibrillated yarn stands out for its unique structure and wide range of applications. Whether it's used in agriculture, construction, or industrial settings, PP fibrillated yarn offers strength and reliability. In this article, we will explore what polypropylene yarn is, its uses, and how PP yarn manufacturers are contributing to its growing demand.

What is Polypropylene Yarn?

Polypropylene yarn, commonly known as PP yarn, is a synthetic fiber made from the polymerization of propylene gas. It is a thermoplastic polymer that is known for its light weight, high strength, and resistance to chemicals and moisture. One of the key advantages of What is polypropylene yarn is its ability to retain its shape and strength even under challenging conditions. This makes it an ideal material for industries that require durable and weather-resistant fibers.

PP yarn meaning encompasses a wide range of applications, from textiles and ropes to packaging and geotextiles. Its versatility allows it to be used in many different forms, including monofilament, multifilament, and fibrillated yarn.

What is PP Fibrillated Yarn?

PP fibrillated yarn is a type of polypropylene yarn that is processed in a way that gives it a net-like, fibrillated structure. This unique texture provides better adhesion and enhances its strength when used in various applications. The fibrillated design makes it ideal for uses that require additional grip and binding capabilities, such as in the production of twine, ropes, and nets.

Key Features and Benefits of PP Fibrillated Yarn

-

Durability and Strength

One of the most notable features of PP fibrillated yarn is its high tensile strength. This makes it ideal for applications where durability is critical, such as in agricultural twine, geotextiles, and packaging materials. The fibrillated structure further improves its grip, enhancing its performance in binding and tying applications. -

Lightweight and Cost-Effective

Polypropylene yarn is known for being lightweight, which makes it easy to handle and transport. Despite its lightweight nature, it offers exceptional strength, making it a highly efficient material for various industries. Moreover, PP fibrillated yarn is cost-effective compared to other synthetic and natural fibers, making it a popular choice for manufacturers looking to reduce costs without compromising quality. -

Chemical and Moisture Resistance

PP yarn has excellent resistance to chemicals, oils, and moisture, making it suitable for harsh environments. Whether used outdoors or in industrial settings, polypropylene yarn retains its properties and resists degradation from exposure to chemicals or moisture. -

UV Stabilization

Some PP yarn manufacturers offer UV-stabilized fibrillated yarn, which provides added protection against the sun’s ultraviolet rays. This feature makes it particularly useful in agricultural applications, where exposure to sunlight is constant. -

Eco-Friendly

Polypropylene yarn is recyclable and can be reused in various applications, reducing its environmental impact. This eco-friendly property adds to the growing popularity of PP yarn in industries that prioritize sustainability.

Applications of PP Fibrillated Yarn

1. Agriculture

PP fibrillated yarn is widely used in the agricultural industry, particularly in the production of baler twine. The yarn’s strength, resistance to moisture, and UV stabilization make it perfect for binding hay, straw, and other crops. Its fibrillated structure ensures a secure grip, preventing slippage and ensuring that the twine holds firmly.

2. Geotextiles and Construction

In the construction industry, PP fibrillated yarn is used in geotextiles, which are essential for soil reinforcement, drainage, and erosion control. The yarn’s durability and resistance to harsh environmental conditions make it an excellent choice for long-term infrastructure projects. Its lightweight nature also makes it easy to transport and install, reducing labor costs.

3. Packaging

PP fibrillated yarn is also used in the packaging industry, especially for tying and bundling products. Its strength ensures that packages are securely bound, reducing the risk of damage during transport.

4. Industrial Applications

In industrial settings, fibrillated yarn is used in the production of ropes, nets, and other materials that require high tensile strength and durability. Its resistance to chemicals and moisture makes it suitable for use in marine environments, oil refineries, and chemical plants.

PP Yarn Manufacturers: Meeting the Growing Demand

The demand for polypropylene yarn, particularly PP fibrillated yarn, has seen significant growth in recent years. As industries continue to recognize the benefits of this versatile material, PP yarn manufacturers are stepping up to meet the growing demand. These manufacturers use advanced technology to produce high-quality PP yarn that meets industry standards and specific application needs.

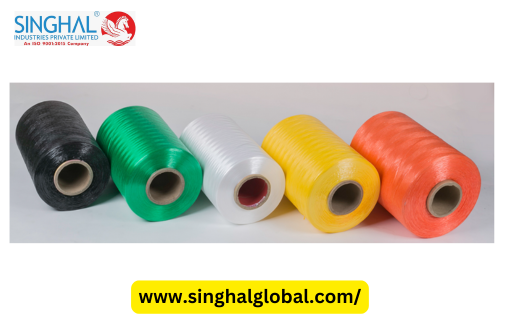

Many PP yarn manufacturers focus on customization, offering different thicknesses, colors, and UV-stabilized options to cater to a variety of industries. Whether for agricultural twine, geotextiles, or industrial ropes, manufacturers are continually improving their production processes to offer durable, cost-effective, and environmentally friendly products.

Conclusion

PP fibrillated yarn is a versatile and durable material with a wide range of applications in agriculture, construction, packaging, and industrial sectors. Its strength, lightweight nature, and resistance to chemicals and moisture make it an ideal choice for industries that require reliable and long-lasting fibers. As the demand for polypropylene yarn continues to grow, PP yarn manufacturers are developing innovative solutions to meet the needs of various industries.

Whether you're looking for agricultural twine, geotextiles, or industrial ropes, PP yarn offers a cost-effective and high-performance solution. Understanding PP yarn meaning and its benefits will help you make informed decisions when selecting materials for your next project.

Here are three short FAQs for PP fibrillated yarn:

-

What is polypropylene yarn?

Polypropylene yarn, also known as PP yarn, is a synthetic fiber made from the polymerization of propylene gas. It is lightweight, durable, and resistant to chemicals and moisture, making it ideal for various industrial, agricultural, and construction applications. -

What is the meaning of PP yarn?

PP yarn meaning refers to yarn made from polypropylene, a thermoplastic polymer. It is commonly used in products like ropes, twine, geotextiles, and packaging materials due to its strength and versatility. -

Where can I find reliable PP yarn manufacturers?

You can find PP yarn manufacturers by searching for specialized suppliers online or contacting local industrial distributors. Many manufacturers offer custom sizes, colors, and UV-stabilized options to meet specific industry needs.