Introduction

PET (polyethylene terephthalate) sheets are essential in various applications due to their clarity, durability, and versatility. Sourcing PET sheets from reputable manufacturers ensures high-quality products suitable for industries such as packaging, signage, construction, and more. This guide explores the benefits of PET sheets, key factors to consider when selecting a manufacturer, and tips for finding reliable pet sheet manufacturer

Benefits of PET Sheets

- Durability: PET sheets are known for their strong impact resistance and durability, making them ideal for applications that require long-lasting materials.

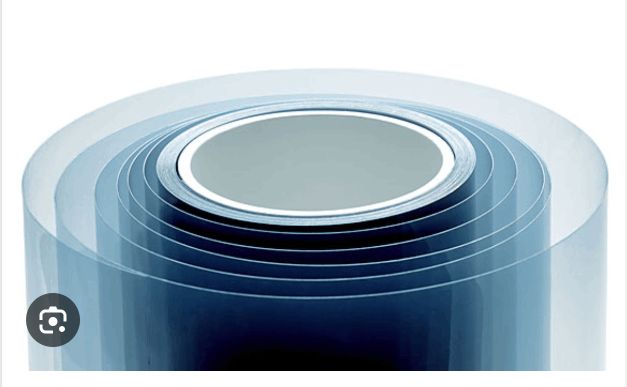

- Clarity and Transparency: The high optical clarity of PET sheets makes them suitable for applications where visual quality is essential, such as displays and packaging.

- Chemical Resistance: PET sheets exhibit resistance to a wide range of chemicals, including acids and bases, enhancing their use in industrial and chemical environments.

- Thermal Stability: PET sheets maintain their properties across various temperatures, providing thermal stability for different applications.

- Lightweight: Their lightweight nature makes PET sheets easy to handle and reduces transportation costs compared to heavier materials.

- Recyclability: PET is a recyclable material, contributing to environmental sustainability and allowing for the reuse of materials in various applications.

- Fabrication Ease: PET sheets can be easily cut, drilled, and formed into various shapes, allowing for customization according to specific needs.

Key Factors to Consider When Choosing a PET Sheet Manufacturer

- Quality Standards: Ensure that the manufacturer adheres to relevant quality standards and certifications. Look for certifications such as ISO to ensure the manufacturer meets industry quality requirements.

- Product Range and Specifications: Verify that the manufacturer offers the types of PET sheets you need, including various thicknesses, colors, and finishes. Check that their products meet your specific technical requirements.

- Reputation and Experience: Research the manufacturer’s reputation and industry experience. A well-established manufacturer with a positive track record is more likely to provide reliable products and services.

- Customization Capabilities: Determine if the manufacturer can accommodate customization requests, such as specific sizes, colors, or special finishes. Custom solutions can tailor the PET sheets to your particular needs.

- Pricing and Terms: Compare pricing from different manufacturers and consider factors such as bulk discounts, payment terms, and shipping costs. Ensure that you understand all costs involved in the transaction.

- Production Capacity and Lead Times: Assess the manufacturer’s ability to handle your order volume and meet delivery deadlines. Ensure they can accommodate both small and large orders efficiently.

- Logistics and Shipping: Consider the manufacturer’s logistics and shipping arrangements, including delivery times, handling procedures, and shipping costs. Efficient logistics are crucial for timely delivery.

- Customer Support: Choose a manufacturer with strong customer support to assist with inquiries, technical issues, and order management. Good support can enhance your overall experience and resolve any potential issues.

How to Find Reliable PET Sheet Manufacturers

- Online Marketplaces: Platforms like Alibaba, Made-in-China, and Global Sources list numerous PET sheet manufacturers. These platforms allow you to compare different manufacturers, view their product offerings, and read customer reviews.

- Manufacturer Websites: Many PET sheet manufacturers have detailed websites that provide information about their products, specifications, and contact details. This can be a valuable resource for researching potential manufacturers.

- Industry Trade Shows: Attending trade shows related to plastics, packaging, and manufacturing provides opportunities to meet PET sheet manufacturers, view product samples, and discuss your needs directly with company representatives.

- Local Distributors: Contact local distributors or sourcing agents who specialize in PET products. They often have established relationships with manufacturers and can assist in finding reliable sources.

- Business Referrals: Seek recommendations from industry peers or business contacts who have experience with PET sheet manufacturers. Referrals can lead to trusted and reliable manufacturers.

- Industry Associations: Join industry associations or organizations related to plastics and manufacturing. These groups often have directories of manufacturers and can provide referrals.

Conclusion

Choosing the right PET sheet manufacturer is crucial for obtaining high-quality materials that meet your specific needs. Consider factors such as quality standards, product range, reputation, customization capabilities, pricing, production capacity, logistics, and customer support when evaluating manufacturers. By utilizing resources like online marketplaces, manufacturer websites, trade shows, local distributors, business referrals, and industry associations, you can find reliable PET sheet manufacturers that provide the products you need for your applications.