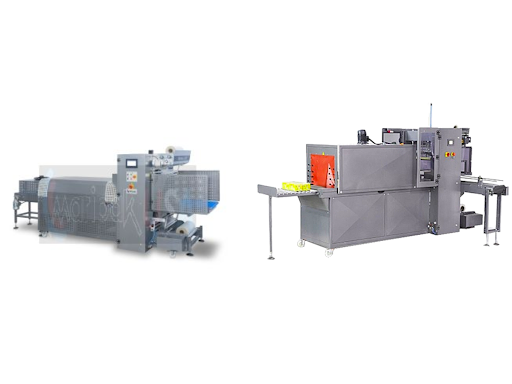

In the dynamic world of packaging, efficiency and reliability are key. For businesses that need to ensure products are well-protected and aesthetically presented, the POF (Polyolefin) shrink film machine is a game-changer. This versatile equipment offers a range of benefits for various industries, making it an invaluable asset for effective shrink packaging. In this blog, we'll explore how POF shrink film machines work, their advantages, and why they are an excellent choice for modern shrink wrap equipment.

Understanding POF Shrink Film Machines

POF shrink film machines use polyolefin film, a popular choice in the packaging industry due to its strength, clarity, and shrinkage properties. The film is designed to shrink tightly around products when exposed to heat, creating a secure and visually appealing wrap. POF shrink film machines are specialized devices that automate this process, enhancing productivity and consistency.

How POF Shrink Film Machines Work

The operation of a POF shrink film machine involves several steps:

-

Film Feeding: The machine starts by feeding the polyolefin film from a roll. The film is unwound and cut to the appropriate size to fit the product.

-

Product Wrapping: The cut film is then wrapped around the product. This can be done manually or through an automated process, depending on the machine's design.

-

Heat Shrinking: Once the product is wrapped, it enters a heat tunnel or chamber. The heat causes the POF film to shrink tightly around the product, conforming to its shape and providing a snug fit.

-

Cooling: After the shrinkage process, the wrapped product is cooled to set the film, ensuring it maintains its tight and secure fit.

Advantages of Using POF Shrink Film Machines

POF shrink film machines offer several benefits that make them a popular choice in the packaging industry:

1. Enhanced Product Protection

One of the primary advantages of using POF shrink film machines is the superior protection they provide for products. This is especially important for products that need to maintain their quality and integrity.

2. Improved Aesthetics

POF shrink film provides a clear, glossy finish that enhances the visual appeal of packaged products. The film's transparency allows consumers to see the product inside, which can be particularly advantageous for retail environments where presentation matters. The shrink-wrap equipment also ensures that the film adheres smoothly without wrinkles or bubbles, giving a professional and attractive appearance.

3. Versatility

POF shrink film machines are highly versatile and can handle a wide range of products, from small individual items to larger bulk packages. The machines can be adjusted to accommodate different sizes and shapes, making them suitable for industries such as food and beverage, pharmaceuticals, and consumer goods.

4. Increased Efficiency

Automating the shrink packaging process with a POF shrink film machine significantly increases efficiency. The machine's ability to quickly and consistently wrap products reduces the need for manual labor and speeds up production lines.

5. Environmental Benefits

POF film is known for its environmentally friendly properties. It is often recyclable and requires less material compared to other types of shrink films. By choosing POF shrink film machines, businesses can contribute to reducing their environmental footprint while still achieving effective packaging.

Selecting the Right Shrink Packaging Machine

1. Machine Type

There are various types of shrink-wrap equipment, including manual, semi-automatic, and fully automatic machines. The choice depends on the scale of your production and the level of automation you require.

2. Film Compatibility

Ensure that the machine is compatible with POF film, as well as any other films you may use. Compatibility affects the machine's performance and the quality of the final product.

3. Production Capacity

Consider the machine's production capacity and speed to ensure it aligns with your business's requirements. Machines with higher capacities are suitable for larger production volumes.

Conclusion

POF shrink film machines are an essential tool in modern packaging, offering numerous benefits such as enhanced product protection, improved aesthetics, and increased efficiency. By utilizing advanced shrink-wrap equipment, businesses can achieve high-quality packaging solutions that not only safeguard products but also contribute to their overall presentation. When selecting a shrink packaging machine, consider factors like machine type, film compatibility, and production capacity to find the best fit for your needs. Embracing POF shrink film machines can lead to significant improvements in your packaging processes, ultimately benefiting your business and your customers.