High-Density Polyethylene (HDPE) bags are an indispensable component in various industries due to their durability, flexibility, and cost-effectiveness. Whether you're managing a retail business, involved in manufacturing, or handling agricultural products, 50 Kg Bag Exporter In India offer a reliable packaging solution that meets a wide range of needs.

In this article, we will delve into what HDPE bags are, their numerous benefits, and their diverse applications. We'll also cover how they compare to other types of bags, their environmental impact, and answer some frequently asked questions to help you understand why HDPE bags might be the right choice for your packaging requirements.

What Are HDPE Bags?

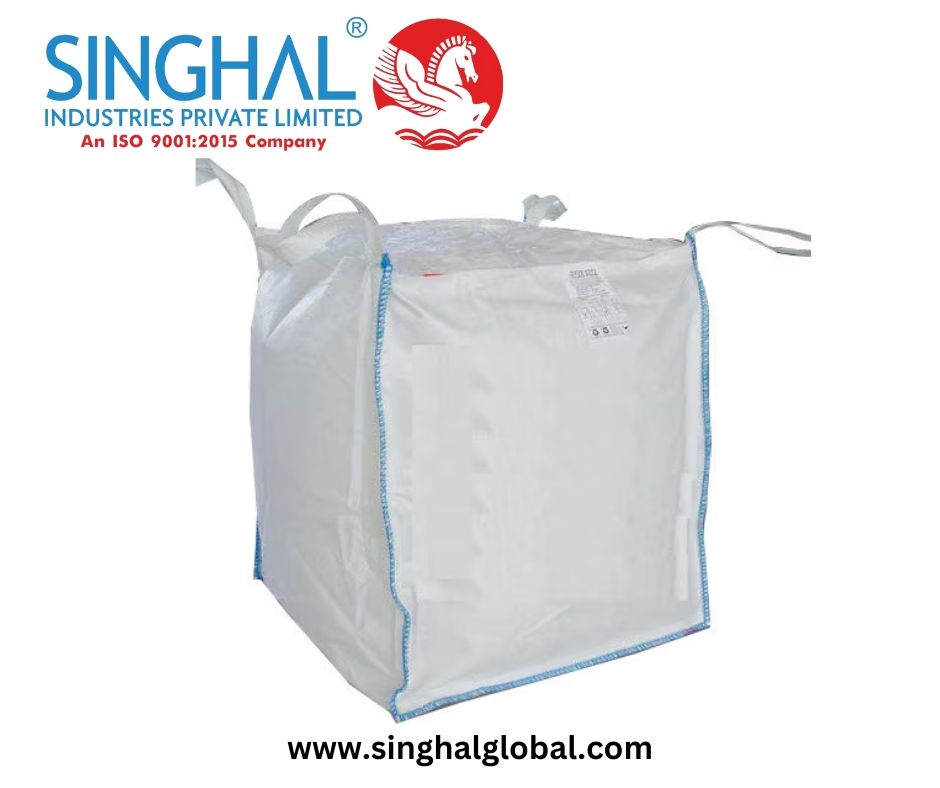

HDPE bags are made from High-Density Polyethylene, a type of thermoplastic polymer. This material is known for its high strength-to-density ratio, which gives HDPE bags their remarkable durability and resistance to impact, moisture, and chemicals. HDPE bags are commonly used for packaging due to their versatility and ability to protect contents effectively.

Key Characteristics of HDPE Bags

-

Strength and Durability: HDPE bags are designed to handle heavy loads without tearing or breaking. Their strength makes them suitable for packaging bulk items and products that require additional protection.

-

Water Resistance: The material is naturally resistant to moisture, making HDPE bags ideal for protecting contents from water damage.

-

Flexibility: HDPE bags can be manufactured in various thicknesses and sizes, allowing for customization to meet specific needs.

-

Cost-Effectiveness: HDPE bags are relatively inexpensive compared to other packaging materials, offering a budget-friendly solution without compromising on quality.

-

Environmental Impact: HDPE is a recyclable material, which contributes to its eco-friendliness when disposed of properly.

Benefits of HDPE Bags

1. Durability and Strength

One of the standout features of HDPE bags is their durability. These bags can handle heavy and sharp objects without easily puncturing or tearing. This strength makes them suitable for a wide range of applications, from grocery shopping to industrial packaging.

2. Moisture Resistance

HDPE bags are naturally resistant to moisture, which helps protect the contents from water damage. This property is particularly valuable in industries such as agriculture, where products need to be shielded from rain and humidity.

3. Customization

HDPE bags can be customized in terms of size, thickness, and color to meet specific packaging requirements. They can be printed with logos, instructions, or product information, making them a versatile choice for branding and marketing.

4. Cost Efficiency

Compared to other types of bags, such as those made from more expensive plastics or materials, HDPE bags are cost-effective. Their production process is relatively simple, which keeps manufacturing costs low and offers savings to the consumer.

5. Environmental Benefits

HDPE is a recyclable material, which means that it can be processed and repurposed into new products. While the environmental impact of plastic products is a concern, using recyclable materials like HDPE contributes to reducing waste and promoting sustainability.

Applications of HDPE Bags

HDPE bags are used across various industries due to their versatility. Here are some common applications:

1. Retail and Grocery Stores

The 50 Kg Plastic Bag are widely used in retail and grocery stores for carrying purchases. Their strength and flexibility make them ideal for handling a variety of items, from groceries to household goods.

2. Industrial Packaging

In industrial settings, HDPE bags are used for packaging bulk materials, chemicals, and construction products. Their durability ensures that the contents are protected during handling and transportation.

3. Agricultural Uses

For agricultural purposes, HDPE bags are used to store and transport seeds, fertilizers, and other agricultural products. Their moisture resistance helps keep these products dry and in good condition.

4. Medical and Pharmaceutical Packaging

In the medical and pharmaceutical industries, HDPE bags are used for packaging medical supplies and pharmaceuticals. Their strength and resistance to chemicals make them suitable for containing sensitive items.

5. Waste Management

HDPE bags are also used for waste management and disposal. They are strong enough to handle various types of waste, including household trash and recyclable materials.

HDPE Bags vs. Other Types of Bags

When choosing a packaging solution, it's important to compare HDPE bags with other types of bags to determine which best suits your needs. Here's how HDPE bags stack up against some common alternatives:

1. HDPE vs. LDPE Bags

-

Durability: HDPE bags are generally stronger and more resistant to punctures and tears compared to LDPE (Low-Density Polyethylene) bags, which are softer and more flexible.

-

Flexibility: LDPE bags are more flexible and stretchable than HDPE bags, making them suitable for applications where flexibility is crucial.

-

Applications: HDPE bags are commonly used for heavier and more rigid items, while LDPE bags are often used for lighter, more delicate products.

2. HDPE vs. PVC Bags

-

Strength: HDPE bags are more resistant to impact and tearing compared to PVC (Polyvinyl Chloride) bags. PVC bags are generally less durable and can become brittle over time.

-

Environmental Impact: HDPE is recyclable, whereas PVC is less environmentally friendly and more challenging to recycle.

-

Cost: HDPE bags are typically less expensive than PVC bags, making them a more cost-effective option for many applications.

3. HDPE vs. Paper Bags

-

Durability: HDPE bags are more resistant to moisture and tearing compared to paper bags, which can become weak when exposed to water.

-

Reusability: Paper bags are biodegradable and can be composted, whereas HDPE bags can be recycled but are not biodegradable.

-

Cost: HDPE bags are generally more affordable than paper bags, particularly for bulk purchasing.

Environmental Considerations

While HDPE bags offer many benefits, it is important to consider their environmental impact. Although HDPE is recyclable, the recycling process is not always widely available or efficient. To mitigate environmental concerns, it's crucial to:

-

Recycle Properly: Ensure that HDPE bags are disposed of in recycling programs that accept polyethylene materials.

-

Reduce Usage: Minimize the use of single-use plastics by opting for reusable alternatives when possible.

-

Support Recycling Initiatives: Advocate for and support recycling programs and initiatives that improve the efficiency of plastic recycling.

Conclusion

HDPE bags provide a versatile, durable, and cost-effective packaging solution for a wide range of applications. Their strength, moisture resistance, and flexibility make them suitable for industries such as retail, agriculture, and manufacturing. While it's important to consider their environmental impact, proper recycling and responsible usage can help mitigate concerns.

Whether you're looking for a reliable way to package products, manage waste, or support branding efforts, HDPE Polythene Bags Manufacturer In India offer a practical and efficient choice. Understanding their benefits and applications can help you make informed decisions and optimize your packaging strategies.

Frequently Asked Questions (FAQs) About HDPE Bags

1. What are HDPE bags made of?

Answer: HDPE bags are made from High-Density Polyethylene, a type of thermoplastic polymer known for its strength and durability.

2. Are HDPE bags recyclable?

Answer: Yes, HDPE bags are recyclable. They can be processed and repurposed into new products. It's important to dispose of them through proper recycling channels.

3. Can HDPE bags be used for food packaging?

Answer: Yes, HDPE bags are commonly used for food packaging. They are safe for storing and transporting food items due to their moisture resistance and strength.

4. What are the benefits of using HDPE bags for packaging?

Answer: HDPE bags offer benefits such as durability, moisture resistance, flexibility, cost-effectiveness, and environmental friendliness due to their recyclability.