Sandwich Panel - An Efficient Building Solution

What are Composite Panels?

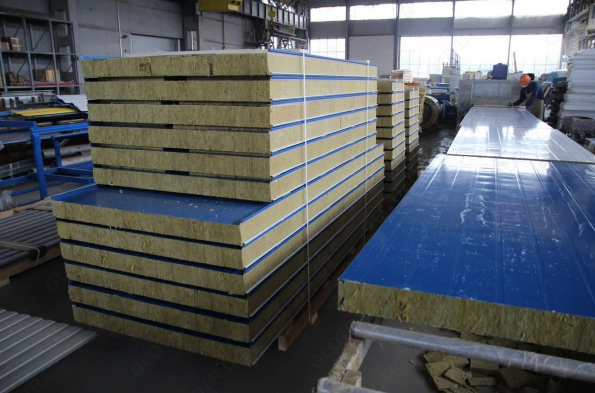

Sandwich Panel are an innovative and efficient building material composed of two thin outer facings or "skins" separated by a thick inner core. The outer facings are generally made of metal or composite materials like fiberglass reinforced plastic while the core is made of insulating materials like rigid foams, wood or mineral wool. This unique composite panel structure provides excellent strength and insulation properties.

Core Materials for Composite Panels

There are a few common materials used as the inner core of Composite sandwich Panels:

- Rigid Polyurethane Foam: A lightweight and durable rigid foam that provides excellent thermal and acoustic insulation. It bonds well to metal and composite skins. Polyurethane foam cores are widely used for industrial and commercial buildings.

- Polyisocyanurate Foam: Similar to polyurethane foam but with enhanced fire resistance characteristics making it suitable for fire rated applications. It has very high insulation efficiency.

- Mineral Wool: Made from mineral fibers, this core material provides fire resistance along with good thermal and acoustic insulation. However, it is heavier than foam cores. Mineral wool cores are primarily used for architectural applications.

- Plywood/Wood: Wood cores provide structural integrity and are an economical option. However, they have lower insulation properties compared to foam cores. Plywood cores are commonly used in residential construction.

Get more insights on Sandwich Panel

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News