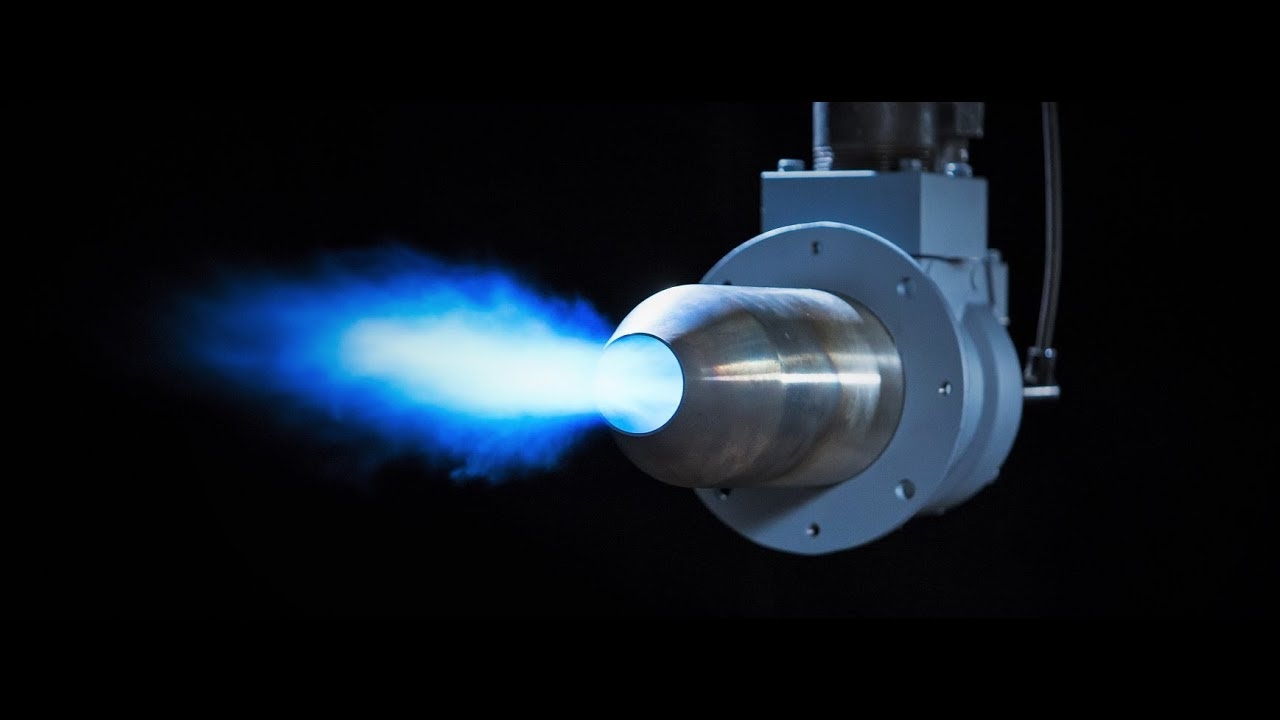

Industrial Burners: Revolutionizing Industrial Combustion A More Efficient Approach

Industrialized burners are specially designed combustion devices used in various industries for processes like heating, drying, sterilization etc. They help in efficiently burning different types of fuels like natural gas, light fuel oil, heavy fuel oil etc and are available in different designs based on the application. Let's understand various types and key components of industrialized burners.

Types of Industrial Burners

Straight Flow Burners: These are the simplest type with one inlet for air and fuel. The air and fuel mix and burn as it exits the burner head in a straight flame. They are used for lower temperature applications up to 800°C.

Radiant Burners: Radiant burners have separate inlets for air and fuel which allows better control over combustion. The flame is detached from the burner head emitting radiant heat useful for applications needing uniform temperature distribution like annealing or heat treatment. They can achieve temperatures up to 1100°C.

Recuperative Burners: To increase combustion efficiency and reduce heat losses, recuperative burners use exhaust gases to preheat the combustion air entering the burner. This recovers some heat that would otherwise be lost with the flue gas. They find application where higher temperatures above 1100°C are required.

Regenerative Burners: Considered one of the most efficient burner types, regenerative burners use ceramic materials like firebricks as heat exchangers to absorb heat from flue gases and transfer it to incoming combustion air. They can achieve extremely high temperatures over 1300°C needed for processes like glass melting.

Key Components of an Industrial Burner

Burner Body: It is the main metallic structure housing other components. Industrial Burners Materials used are cast iron or steel depending on the process temperature.

Air Inlet: Primary air is supplied through an inlet to provide oxygen for combustion. Secondary air inlets are provided in some burners for better mixing.

Fuel Inlet: Liquid or gas fuel enters the burner body through this inlet which may contain valves, regulators etc to control fuel flow.

Ignition System: A pilot flame or hot surface igniter is used to initiate combustion. Standing pilot flames are commonly used which burn continuously.

Flame Support: Refractory lining or customized flame holders inside the burner helps in anchoring and stabilizing the flame during combustion.

Burner Nozzle: Atomization nozzles are used for liquid fuels to finely spray the fuel which mixes thoroughly with air enhancing combustion. Gas fuels directly mix with air.

Exhaust Connection: Mounted at the rear, it carries the flue gases and combustion byproducts out of the system. Draft diverter is sometimes included to prevent backdraft.

Control Panel: Provides necessary controls to monitor and regulate combustion like fuel/air flow, temperature etc. interfaced with safety shutdown systems.

Applications of Industrialized burners

Heating Processes: Burners are used for process heating in industries like steel, foundries, plastics and many more. Fuel-air mixture burns and transfers heat to the work pieces or heating chambers.

Drying Applications: Burners generate hot air or thermal radiation to dry materials rapidly in industries like paper, textiles, food etc. avoiding moisture related issues during processing.

Heat Treatment: Controlled flame-based heating and cooling is done using burners to achieve specific material properties through processes like annealing, hardening, normalizing etc.

Sterilization: Burners help in disinfecting and sterilizing equipment, packaging materials and containers in pharmaceutical and medical industries through application of high temperatures.

Glass Melting Furnaces: Regenerative and other high temperature burners come in contact with molten material and supply necessary thermal energy to melt raw materials during glass production.

Burner Selection Criteria

When selecting a suitable burner for any industrial process, key factors that determine the choice are fuel type, required process temperature, space availability, emissions norms, safety and reliability. Manufacturers usually assist in evaluating these criteria and recommending appropriate burner models. Proper burner selection and installation is critical for safe, efficient and compliant plant operations.

burner selection also factors in maintenance accessibility, compatibility with plant automation & controls, certification approvals, fuel changeover flexibility if needed in future. Life cycle cost including efficiency gains over time also influence the decision. Local service support availability is another deciding aspect.

industrialized burners have come a long way in design and performance. Today's advanced models with low NOx technologies protect environment while optimal combustion enhances process yield and quality. Integration of automation and real-time diagnostics is making plant operations more sustainable with predictive maintenance. With continuous technology advancement, industrialized burners will keep playing a crucial role as backbone of combustion systems powering various manufacturing industries.

Get More Insights On Industrial Burner

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News