CFW Oil Seals: A Legacy of Sealing Excellence

In the intricate world of machines, where relentless motion and friction meet, a silent guardian stands watch: the CFW oil seal. More than just a simple ring, it's a testament to precision engineering and a symbol of the Carl Freudenberg company's commitment to sealing excellence. Let's delve into the history, technology, and applications of CFW oil seals, exploring what makes them a trusted choice across industries.

A Legacy Rooted in Innovation: The Birth of CFW

The story of CFW oil seals begins in 1847 with Carl Freudenberg, a visionary entrepreneur who established a company in Weinheim, Germany. Initially focusing on leather processing, Freudenberg soon recognized the growing need for innovative sealing solutions in the burgeoning industrial landscape. This pioneering spirit led to the development of the first Freudenberg oil seal in 1929, a pivotal moment that revolutionized machine performance and reliability.

CFW: A Mark of Quality

The name "CFW" itself stands as a tribute to the company's heritage. It's an abbreviation for "Carl Freudenberg Weinheim," a nod to the founder and the birthplace of these innovative seals. CFW oil seals quickly gained recognition for their superior quality, offering several key advantages:

- High-Performance Materials: CFW seals are meticulously crafted using top-tier materials. Nitrile rubber (NBR) is a popular choice for its excellent resistance to oil, grease, and moderate temperatures. For more demanding environments, Fluorocarbon (FKM), also known as Viton®, offers exceptional resistance to heat, chemicals, and fuels.

- Precision Engineering: Every CFW oil seal is meticulously designed and manufactured to meet exacting tolerances. This ensures a perfect fit with the shaft and housing, preventing leaks and maximizing sealing effectiveness.

- Durability and Reliability: CFW seals are built to endure the rigors of everyday operation. The robust construction and high-quality materials ensure they can withstand extended use, minimizing maintenance downtime.

A Spectrum of Solutions: CFW Oil Seals for Diverse Applications

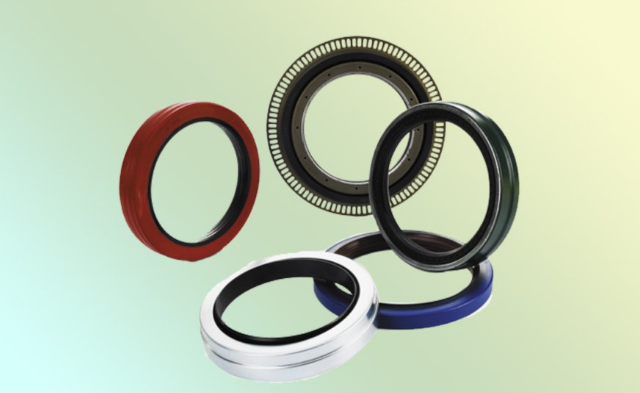

CFW oil seals are not a one-size-fits-all solution. Freudenberg offers a comprehensive range of CFW seals to cater to the specific needs of various industries. Here's a glimpse into some of the most common types:

- Single Lip Seals: These workhorses provide excellent sealing performance for moderate pressure and speed applications.

- Double Lip Seals: As the name suggests, these seals boast two sealing lips, ideal for high-pressure environments where leak prevention is paramount.

- TC (Temperature Compensated) Seals: Designed for environments with extreme temperature fluctuations, TC seals utilize a special spring material that maintains sealing effectiveness across a wider range.

- Cassette Seals: Offering superior sealing performance and customization options, these modular seals are often used in critical applications.

- Material-Specific Seals: CFW offers a variety of material options, including PTFE (Teflon®) for applications requiring exceptional chemical resistance.

Beyond the Single Seal: CFW and the Power of Seal Kits

CFW doesn't just provide individual oil seals. They also offer comprehensive seal kits that encompass a collection of seals specifically designed for a particular machine or application. A CFW seal kit might typically include:

- Crankshaft Seals: These vital seals prevent oil leaks from the crankcase, the heart of an engine.

- Camshaft Seals: They ensure oil doesn't leak around the camshaft, the component responsible for valve timing.

- Valve Stem Seals: These seals prevent oil from entering the combustion chamber via the valve stems.

- Application-Specific Seals: Some kits may include seals for gearboxes, differentials, or other specific components depending on the machine.

Using a CFW seal kit offers several advantages:

- Convenience: It provides all the necessary seals for a specific repair in a single package, saving time and effort in sourcing individual parts.

- Compatibility: The seals in a CFW kit are guaranteed to be compatible with each other and designed for the specific application, ensuring optimal performance.

- Quality Assurance: By using a CFW seal kit, you can be confident that all components meet the company's high-quality standards.

CFW vs. NOK Oil Seals: Choosing the Right Brand

NOK (NOK Corporation) is another leading manufacturer of high-quality oil seals. Both CFW and NOK offer a wide range of products and are known for their reliability. When choosing between the two, consider factors like:

- Specific Application: Research the specific needs of your application and compare the features and materials offered by both brands.

- Availability: Check which brand offers the specific type and size of seal you require.

- Brand Reputation: Both CFW and NOK are reputable brands. However,

See more

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News