What Are the Many Stages of the Molding Process of the Top Pet Bottle Mold Manufacturer?

Your search for the best pet bottle mold manufacturer ends here. Only the best molds manufacturer will provide well-designed molds that make high-quality pet bottles. With stiff competition among the pet bottles in the market, it is essential to have superior molds suitable for the many advanced machines.

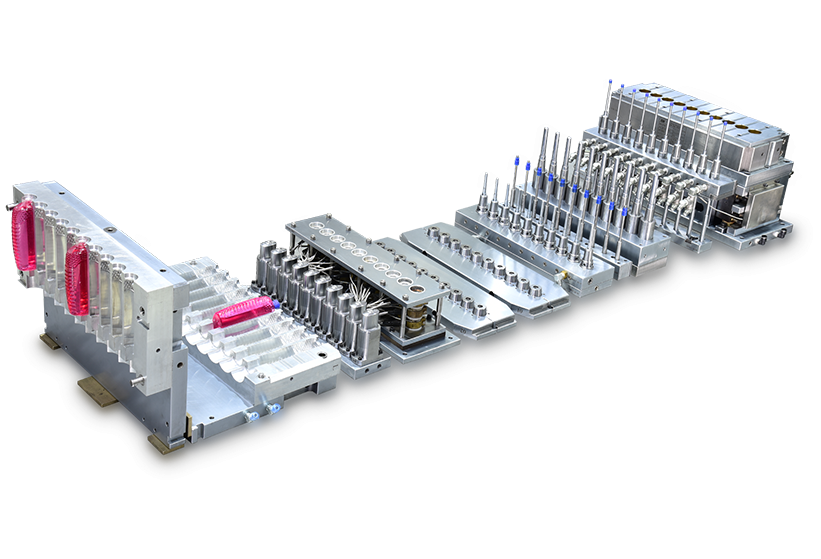

The experienced mold manufacturer will have the R&D or research and development facilities for innovatively designing the molds per your specific needs at competitive costs. It will help them do all the molding processes to shape the pet bottles per your desired profile. It will include injection and extrusion molding processes to produce the best pet bottles.

Continue reading this blog to learn about all the many stages of the molding process for buying the best molds from the top pet bottle mold manufacturer to outsmart the competition and increase sales.

What are the many molding stages by the top pet bottle mold manufacturer?

Pet bottles are in high demand as they are used for packing potable water and other drinks worldwide. It is the reason that the IMARC group predicts the PET bottle market size will grow at a CAGR of 3.3% to reach 60.3 from 44.1 billion dollars from 2023 to 2032. The top pet bottle mold manufacturer makes these bottles with PET or polyethylene terephthalate, which is both light and robust. The experienced molds manufacturer does the following molding stages to convert PET into desired bottle profiles using injection or extrusion molding.

-

The first stage of the molding process is the preparation of melting the plastic resins using a regulated heating mechanism to ensure that the liquid gets melted uniformly

-

Shaping is the second stage of introducing the prepared liquid between the molds to take the desired shape to cool later

-

The third stage is the ejection of the shaped PET bottle to undergo a finishing process later.

ADS or ACME Drinktec Solutions is the leading molds manufacturer for single-stage machines with over 20 years of experience in making Molds for 50MB Machine, 12 M, ISBM, and many others with high quality at competitive costs.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News