Adtech ceramic foam filters are used to produce high-quality aluminum foils

Ceramic Foam Filter Filtration removes entrained solids from molten aluminum alloy before casting. When the molten aluminum is solidified, when these inclusions appear in the final cast product, they will cause the ductility of the final aluminum product to decrease or the trimming characteristics of the final aluminum product to be poor. Therefore, removing the entrained solid from the molten aluminum is important before casting it into a solid.

The filtering result of Ceramic Foam Filters Filtration depends on the chemical composition of the inclusions in the melt, the shape of the ceramic foam filter plate, the size of the filter plate, the metal flow rate, the wettability of the surface of the filter plate to aluminum, and the size of the inclusions.

When the melt containing inclusions passes through the ceramic foam filter, the inclusions are trapped on the surface of the particles. Inclusions larger than 30um are filtered through mechanical interception, and those smaller than 30um are retained by surface tension.

Ceramic Foam Filter Filtration used in aluminum foundries can remove the inclusions generated between the refining system and the mold table. Filter by reducing the content of non-metallic inclusions and oxide film in the molten metal. The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the metal solidification process. Therefore, the quality and productivity in downstream operations such as forging, extrusion, and rolling are guaranteed.

Generally, filtration methods are used to remove entrained solids from molten aluminum alloys before casting.

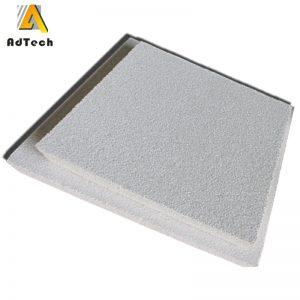

Ceramic foam filters are used to produce high-quality aluminum plates, aluminum foils, and other castings. It can effectively remove the inclusions in liquid aluminum through physical adsorption and chemical adsorption, thereby eliminating defects in castings, improving the quality of castings, and providing excellent materials for further processing. A ceramic foam filter can be used to remove oxides and other inclusions. The ceramic foam filter is a white or milky white honeycomb ceramic filter.

Ceramic foam filter (CFF) produced by Filter Foam Manufacturers AdTech maintains high strength and has excellent resistance to chemical abrasion of castings. The network of pores in the filter provides a larger surface area for the retention of inclusions. The filter size range is 7, 15, 17, 23, and 26 inches, and the pore size is 20 to 80 PPI. For high cleanliness requirements, a double filter with two pores can be used.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News