Enhance Product Development with Early Supplier Involvement at GV Mold

GV Mold has revolutionized the plastic injection molding industry by integrating Early Supplier Involvement (ESI) into its product development process. ESI is a strategic approach that engages suppliers from the earliest stages of design and development, fostering collaboration and innovation. By leveraging supplier expertise, GV Mold ensures efficient production, cost savings, and high-quality results for clients across diverse industries.

The Concept of Early Supplier Involvement

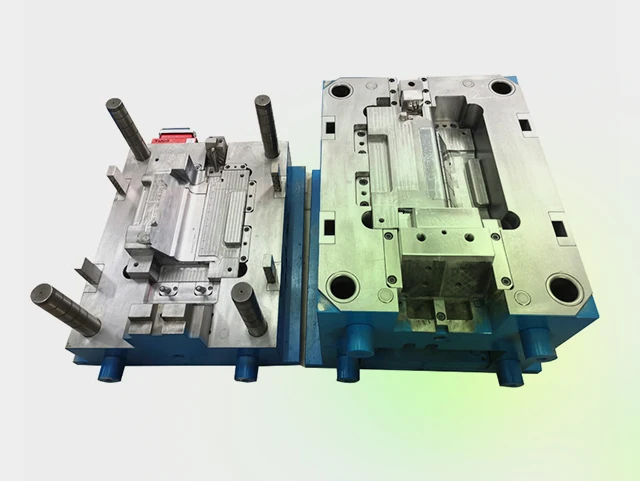

Early Supplier Involvement is a proactive strategy where suppliers are included in the product development process right from the conceptual phase. This collaboration allows manufacturers to tap into the specialized knowledge and capabilities of their suppliers, custom plastic injection mold optimizing designs and streamlining production. At GV Mold, ESI is more than a methodology—it’s a cornerstone of their commitment to delivering innovative solutions that meet market demands while reducing risks and costs.

Benefits of ESI in Product Development

The advantages of Early Supplier Involvement are transformative for both manufacturers and suppliers. By involving suppliers early, GV Mold identifies potential challenges during the design phase, avoiding costly modifications during production. This early collaboration enhances product quality, reduces lead times, and drives cost efficiency. Additionally, ESI fosters innovation by encouraging suppliers to contribute creative ideas and advanced technologies, resulting in products that stand out in competitive markets.

Accelerating Time-to-Market

One of the most significant benefits of ESI at GV Mold is its ability to accelerate time-to-market for new products. By addressing design challenges early and streamlining communication between stakeholders, ESI eliminates bottlenecks that often delay production. Suppliers provide valuable insights on material selection, tooling design, and manufacturing processes, ensuring that every stage progresses smoothly. This efficiency enables GV Mold’s clients to launch their products faster while maintaining high standards of quality and performance.

Cost Savings Through Collaboration

Cost efficiency is a critical aspect of product development, and GV Mold excels at achieving this through ESI. By engaging suppliers early, the company identifies opportunities for cost reduction in areas such as material selection, tooling design, and production methods. Suppliers often suggest innovative alternatives that balance performance with affordability. This collaborative approach minimizes waste, reduces rework costs, and ensures that projects remain within budget without compromising on quality.

Enhancing Product Quality

Quality assurance is integral to GV Mold’s operations, and ESI plays a vital role in achieving superior results. Early supplier engagement allows for thorough design reviews and validation processes that prevent defects before production begins. Suppliers bring their expertise in materials and manufacturing techniques to ensure that every component meets stringent quality standards. This proactive approach results in durable, reliable products that perform consistently across diverse applications.

Fostering Innovation Through Supplier Expertise

Innovation thrives in collaborative environments, and GV Mold’s implementation of ESI exemplifies this principle. By involving suppliers in the early stages of development, the company encourages them to contribute ideas for improving designs or introducing advanced technologies. Suppliers’ specialized knowledge often leads to breakthroughs that enhance product functionality or reduce environmental impact. This synergy between GV Mold and its supply partners drives continuous improvement and keeps clients ahead in competitive markets.

Why Choose GV Mold for ESI Integration?

GV Mold’s mastery of Early Supplier Involvement makes them an ideal partner for businesses seeking efficient product development solutions. Their ability to foster collaboration between manufacturers and suppliers ensures seamless execution from concept to production. With a focus on innovation, cost savings, and quality enhancement, GV Mold delivers results that exceed expectations while helping clients achieve their goals faster.

By integrating ESI into its operations, GV Mold continues to set benchmarks in the plastic injection molding industry, enabling businesses to develop state-of-the-art products with precision and efficiency.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News