Types And Benefits Of Paper Egg Tray Making Machines

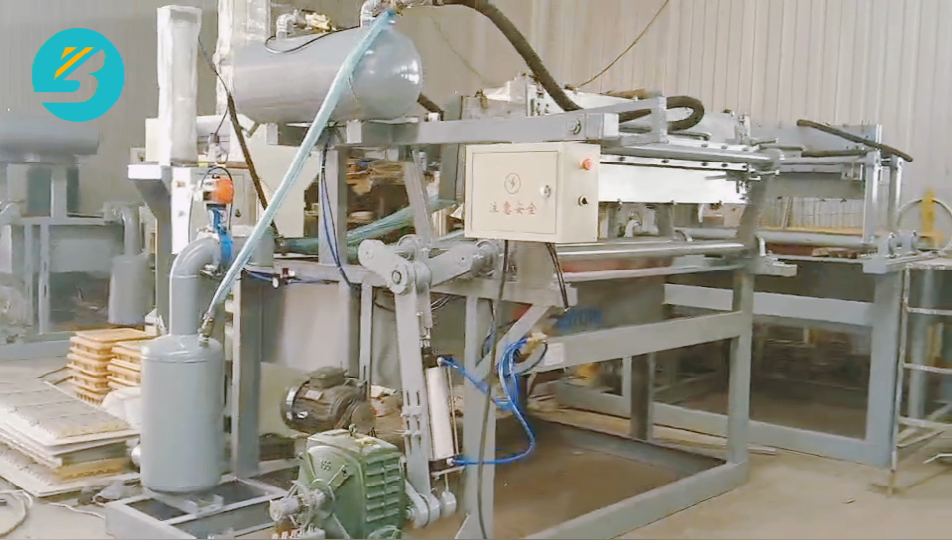

In previous years, people used plastic egg trays as being the primary storage for eggs. However, with all the expansion of environmental awareness, manufacturers have turned into make paper egg trays which can be much economical and ecologically friendly. The egg tray making machine operates by utilizing waste paper as its raw materials. It can not discharge any wastages instead recycles this type of water(recicla este papel) collected throughout the procedure. The most recent models are versatile and can also produce trays for apples, shoes, and also bottles. Its functionality will make it economical with a high rate of investment. The machine has become available in three different versions.

The foremost and most typical may be the fully automatic design. The devices operate efficiently to yield high output. When you have a business with high demand, then it is the appliance to acquire. It can work almost all the time without suffering any malfunctions. Also, operations are cheap because it fails to require manual input. Only at step one, where you will need to feed it with all the waste paper, that input is required. Otherwise, it is adequate to satisfy any demands. The ideal within this category can accommodate around 70 molds, thus producing 6000 trays every hour.

The second version is semi-automatic designs. Such types are compatible with locations with average demand. Great for those who do not possess long terms wants to produce egg trays. However, their prices are quite reasonable. The production capacity also varies, nevertheless it cannot meet extraordinary levels. Additionally, you have to incur employing a few employees to carry out the few tasks it cannot solely handle. Every hour, it can make a maximum of 2500 trays.

The manual model will be the cheapest one of them all, for investors that do not need to incur costs when it comes to energy and repairs. However, its operations can be costly. You will need to buy a lot in labor otherwise, you will find no production. It really is suitable in places with cheap work, and production demands are low thus, it may easily fit into small-scale industries. Also, it utilizes natural drying, which happens to be easily accessible at no cost. The normal output for this model is 1500 trays (equipo de maples)every hour. It may appear cheap, although the overhead costs could start getting in the strategy for profits.

Benefits.

Making an investment in the egg tray making machine is a venture that will assist your company to comprehend profits in a short period. The markets of eggs are continuously increasing and, consequently, that from egg trays. The possible to expand and turn into an important supplier from the commodities is high. The machines work on an hourly basis and can produce a wide range of egg trays, thus low energy costs. Based on the kind of needs that you may have, you are able to select either of the above mentioned. Nonetheless, the operations are green, from recycling waste paper to producing consumer-friendly end products.

These information sheds light on all kinds of egg tray making machines(Detalles de la empresa Beston) in Kyrgyzstan. Each will work with an identical principle but have different capabilities depending on their functionality levels.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News