Ceramic Injection Moldings Market Growth: Share, Value, Size, Trends, and Insights Ceramic Injection Moldings Market Industry Statistics: Growth, Share, Value, Insights, and Trends

"Ceramic Injection Moldings Market Size And Forecast by 2031

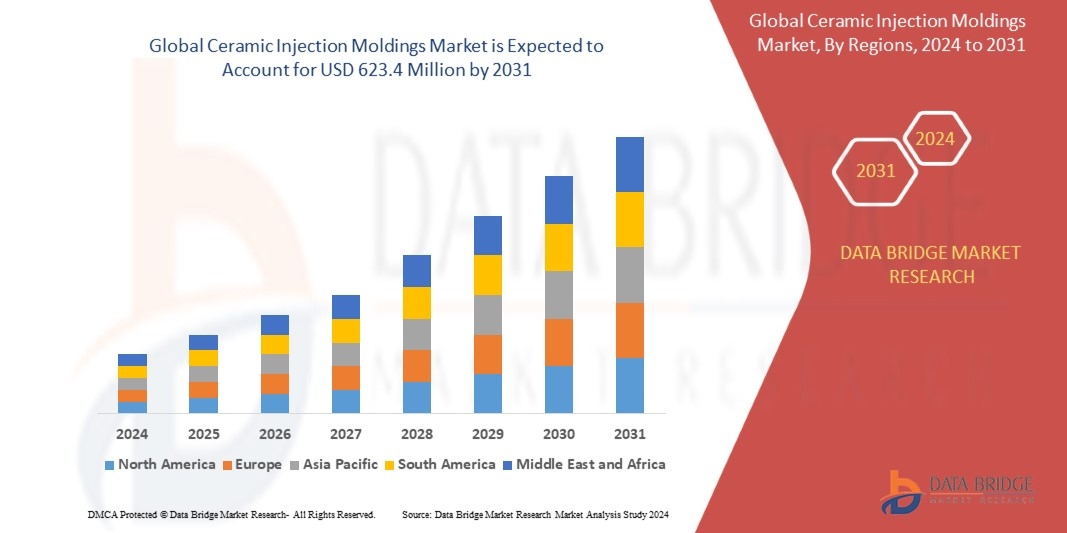

According to Data Bridge Market Research Data Bridge Market Research analyses that the Global Ceramic Injection Moldings Market which was USD 428.5 Million in 2023 is expected to reach USD 623.4 Million by 2031 and is expected to undergo a CAGR of 4.80% during the forecast period of 2023 to 2031

Our comprehensive Ceramic Injection Moldings Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-ceramic-injection-molding-market

**Segments**

- By Material: Ceramic Materials, Metal Injection Molding Feedstocks, Others

- By Industry Vertical: Healthcare, Automotive, Aerospace, Electronics, Others

- By Geography: North America, Europe, Asia-Pacific, South America, Middle East and Africa

Ceramic injection molding (CIM) is a highly versatile manufacturing process that allows for the production of complex and intricate ceramic components. The market for ceramic injection moldings is segmented based on various factors such as material, industry vertical, and geography. The material segment includes ceramic materials, metal injection molding feedstocks, and others. Ceramic materials are widely used in CIM due to their excellent properties such as high temperature resistance, wear resistance, and biocompatibility. Metal injection molding feedstocks are also gaining traction in the market, especially in industries like automotive and aerospace. The industry vertical segment consists of healthcare, automotive, aerospace, electronics, and others. The healthcare sector is a key consumer of ceramic injection moldings due to the growing demand for medical implants and devices. The automotive and aerospace industries also heavily rely on CIM for producing components with high precision and durability. Geographically, the market is divided into North America, Europe, Asia-Pacific, South America, and Middle East and Africa.

**Market Players**

- CoorsTek Inc.

- Kyocera Corporation

- Morgan Advanced Materials

- 3M

- NGK Insulators Ltd.

- Sembach Technical Ceramics

Key market players in the ceramic injection moldings market include leading companies such as CoorsTek Inc., Kyocera Corporation, Morgan Advanced Materials, 3M, NGK Insulators Ltd., and Sembach Technical Ceramics. These players are at the forefront of technological advancements in ceramic materials and injection molding processes. CoorsTek Inc. is known for its innovative solutions in advanced ceramics and has a strong presence in the healthcare and automotive sectors. Kyocera Corporation, a global leader in ceramics manufacturing, offers a wide range of products for various industries, including CIM. Morgan Advanced Materials specializes in materials engineering and provides high-performance ceramic components for critical applications. 3M, a diversified technology company, has a portfolio of ceramic injection molding products catering to different industrial needs. NGK Insulators Ltd. is a key player in the market, known for its expertise in electrical insulation and ceramic components. Sembach Technical Ceramics is a reputed manufacturer of technical ceramics and is a trusted supplier for many industries requiring precision components.

https://www.databridgemarketresearch.com/reports/global-ceramic-injection-molding-market The global ceramic injection molding market is witnessing significant growth due to the increasing demand for complex ceramic components across various industries. One of the key trends shaping the market is the rising adoption of advanced ceramic materials with superior properties such as high temperature resistance, excellent wear resistance, and biocompatibility. This trend is driving the demand for ceramic injection molding in sectors such as healthcare, automotive, aerospace, and electronics. Additionally, the use of metal injection molding feedstocks is gaining traction, particularly in industries that require high precision and durability in component manufacturing.

In terms of industry verticals, the healthcare sector stands out as a major consumer of ceramic injection moldings. The growing demand for medical implants, devices, and equipment with superior performance attributes is fueling the market growth in this segment. Furthermore, the automotive and aerospace industries are leveraging ceramic injection molding technology to produce lightweight and high-strength components for enhancing overall efficiency and performance of vehicles and aircraft. The electronics industry is also embracing ceramic injection moldings for the fabrication of intricate components used in various electronic devices and systems.

Geographically, North America and Europe are leading regions in the ceramic injection molding market due to the presence of key market players, technological advancements, and high adoption rates across industries. However, the Asia-Pacific region is expected to witness substantial growth in the coming years, driven by rapid industrialization, increasing investments in research and development, and the expanding manufacturing sector. South America and the Middle East and Africa regions are also showing promising growth prospects, supported by the growing demand for advanced ceramic components in sectors such as healthcare, automotive, and aerospace.

The competitive landscape of the ceramic injection molding market is characterized by intense competition among key players such as CoorsTek Inc., Kyocera Corporation, Morgan Advanced Materials, 3M, NGK Insulators Ltd., and Sembach Technical Ceramics. These companies are focusing on research and development activities to introduce innovative products and enhance their market presence. Partnerships, collaborations, and mergers and acquisitions are common strategies adopted by market players to strengthen their market position and expand their global footprint. Additionally, increasing investments in advanced manufacturing technologies and automation are expected to drive further growth and innovation in the ceramic injection molding market.**Segments**

- Global Ceramic Injection Moldings Market, By Materials (Alumina, Zirconia, Ferrite, Others), Application (Medical and Healthcare, Industrial Machinery, Consumer Products, Automotive, Aerospace, Others) - Industry Trends and Forecast to 2031.

Ceramic injection molding (CIM) is a specialized manufacturing process that caters to the production of intricate and complex ceramic components. The market for ceramic injection moldings is segmented based on various factors such as material, industry vertical, and geography. In terms of materials, key categories include Alumina, Zirconia, Ferrite, and others. Alumina is widely employed due to its high strength and thermal properties, while Zirconia is valued for its mechanical properties and biocompatibility. Ferrite, known for its magnetic properties, also finds applications in various industries. The applications span across various sectors such as Medical and Healthcare, Industrial Machinery, Consumer Products, Automotive, Aerospace, and others. These segments delineate the diverse utilization of ceramic injection moldings across a wide range of industries with burgeoning growth prospects for the forecast period until 2031.

**Market Players**

- Form Technologies Company (U.S.)

- ARBURG GmbH + Co KG (Germany)

- Akron Porcelain & Plastics Co. (U.S.)

- Ortech Advanced Ceramics (U.S.)

- Epsom Atmix Corporation (Japan)

- INDO-MIM (U.S.)

- Morgan Advanced Materials (U.K.)

Form Technologies Company, a U.S.-based leading player, specializes in advanced ceramic technologies with a strong market foothold. ARBURG GmbH + Co KG from Germany is recognized for its precision in injection molding machinery, catering to the ceramic components sector. Akron Porcelain & Plastics Co. based in the U.S. is known for its innovative solutions in ceramic injection molding processes. Ortech Advanced Ceramics, a U.S. company, stands out for its expertise in advanced ceramic materials and manufacturing techniques. Epsom Atmix Corporation, a Japanese company, is renowned for its contributions to ceramic injection molding advancements. INDO-MIM, a U.S.-based firm, brings expertise in metal injection molding processes for varied applications. Morgan Advanced Materials, headquartered in the U.K., specializes in providing high-performance ceramic components for critical applications across industries. These market players signify the competitive landscape's diversification and specialization, contributing significantly to the technological advancements and market growth of the global ceramic injection moldings industry.

The global ceramic injection moldings market continues to witness substantial growth driven by increasing demand across diverse industries for specialized ceramic components. The industry trends and forecasts until 2031 reflect a positive outlook characterized by the adoption of advanced ceramic materials with superior properties. Key industry verticals, including Medical and Healthcare, Industrial Machinery, Consumer Products, Automotive, Aerospace, and others, are driving the market's growth trajectory. The healthcare sector's reliance on ceramic injection moldings for high-performance medical devices and implants is a significant growth driver. Additionally, the automotive and aerospace industries are leveraging the technology to enhance vehicle and aircraft efficiency. The adoption of ceramic injection moldings in consumer products, industrial machinery, and other sectors further accentuates the market's expansion.

Geographically, North America and Europe lead the ceramic injection moldings market due to established players, technological advancements, and high adoption rates. However, the Asia-Pacific region is poised for substantial growth fueled by industrialization, R&D investments, and manufacturing sector expansion. South America and the Middle East and Africa also present growth opportunities driven by increasing demand across industry verticals. The competitive landscape with major players like CoorsTek Inc., Kyocera Corporation, Morgan Advanced Materials, and others focusing on innovation, partnerships, and strategic collaborations underscores industry dynamism, fostering growth and innovation in the ceramic injection moldings market. The market's sustained expansion and technological advancements are expected to further elevate its significance and contribution to various sectors globally.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Ceramic Injection Moldings Market : https://www.databridgemarketresearch.com/reports/global-ceramic-injection-molding-market/companies

Key Questions Answered by the Global Ceramic Injection Moldings Market Report:

- What is the current state of the Ceramic Injection Moldings Market, and how has it evolved?

- What are the key drivers behind the growth of the Ceramic Injection Moldings Market?

- What challenges and barriers do businesses in the Ceramic Injection Moldings Market face?

- How are technological innovations impacting the Ceramic Injection Moldings Market?

- What emerging trends and opportunities should businesses be aware of in the Ceramic Injection Moldings Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-meat-and-poultry-processing-market

https://www.databridgemarketresearch.com/reports/global-professional-haircare-products-market

https://www.databridgemarketresearch.com/reports/global-flu-vaccines-market

https://www.databridgemarketresearch.com/reports/global-flexographic-printing-doctor-blade-market

https://www.databridgemarketresearch.com/reports/global-standalone-mounted-video-encoders-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 982

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News