The Palm Kernel Shell Machine - Get Appropriate One

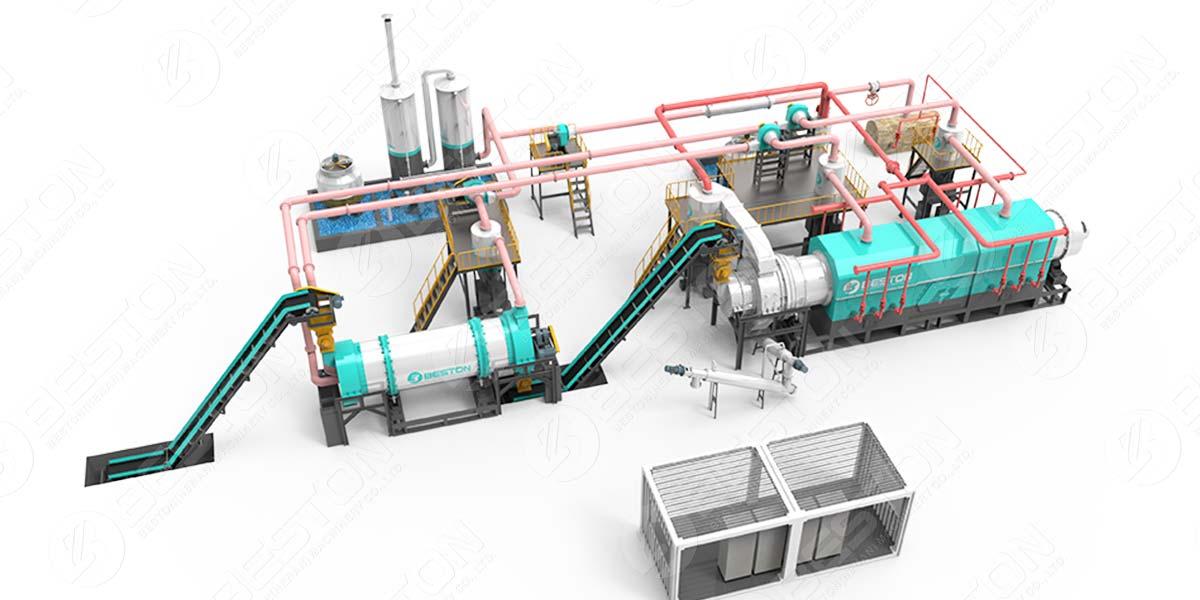

Palm kernel shells are some of the cheapest types of pollution that can be found inside our environment. So that you can deal with this problem, companies have created a palm shell machine. This machine is accountable for process the shells and converting them in to a new resource that can be used in a number of industries. So read on when we discuss the operations of a palm kernel shell charcoal making machinery and its carbonization tech.

The charcoal created from the palm shells has a few of the highest caloric values in the marketplace. Additionally, these are 100% non-toxic, smoke-free, clean, tasteless, and they are always on the go considering they are found in other industries. Palm shell charcoal may be used inside the agriculture field, for civilian needs, inside the pharmaceutical field, and then in others. It could even be used as a method of restaurant fuel and also for brick making.

Ahead of the initial processing may start, the raw material ought to be dried, this makes sure that the conclusion item is in the highest standards. After drying the shells are sent straight into the carbonization furnace where they can be heated to some maximum of 600 degrees C and no less than 400 degrees C. Processing is generally fast and lasts just around quarter-hour. Click here to know more: https://bestoncompany.com/charcoal-making-machine/.

If any tail gas is generated along the way, it will be recycled being a fuel source. Right after the materials are already processed, purified and condensed, they are sent to the dedusting system. This helps to ensure that pollutants are removed. When completed, charcoal, wood vinegar, and tar are made.

As a result of difference in organics, the various raw materials being processed often contain different numbers of moisture. Hence the very last products and parameters may vary according to the form of equipment. The temperature furnace is rarely heated to lower than 700 degrees C. When the yield is quite large, the method accelerates. Get a high performance coconut charcoal machine here.

As soon as the process speeds up, in addition, it lowers the price of operations. Because there are also high demands for byproducts, there is always a need for that tech. Manufacturers are skilled enough to develop and tailor machines to accommodate any customers' needs. So before you purchase a unit, be sure to speak to a manufacturer to talk about your choices.

Many years of research and continued development have led to the improvements which can be seen with one of these machines. Carbonization machines are taking the markets as well as the globe by storm making use of their many capabilities. They supply several benefits and advantages on the environment and persons nearby. Why not visit the site: https://bestoncompany.com/biochar-production-equipment/.

While we conclude, we have now just considered the palm shell charcoal making machine. We have also considered the procedure and some of the benefits that are included with it. These machines are already being used in several countries world wide and so are highly preferred. Manufacturers also make sure that they send along properly trained engineers who share knowledge and train all of your staff that you may employ its best to remember that you ought to properly train your operators before they use these appliances.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News