A Comprehensive Guide to Container Liners: Protecting Cargo for Efficient Transport

Container liners are essential tools in the logistics and shipping industry, designed to protect bulk cargo during transportation. These specialized liners provide a barrier between the cargo and the container, helping to prevent contamination, moisture damage, and other potential hazards. This article will explore the features, benefits, and applications of container liners, along with insights into sourcing options from reputable container liners manufacturers.

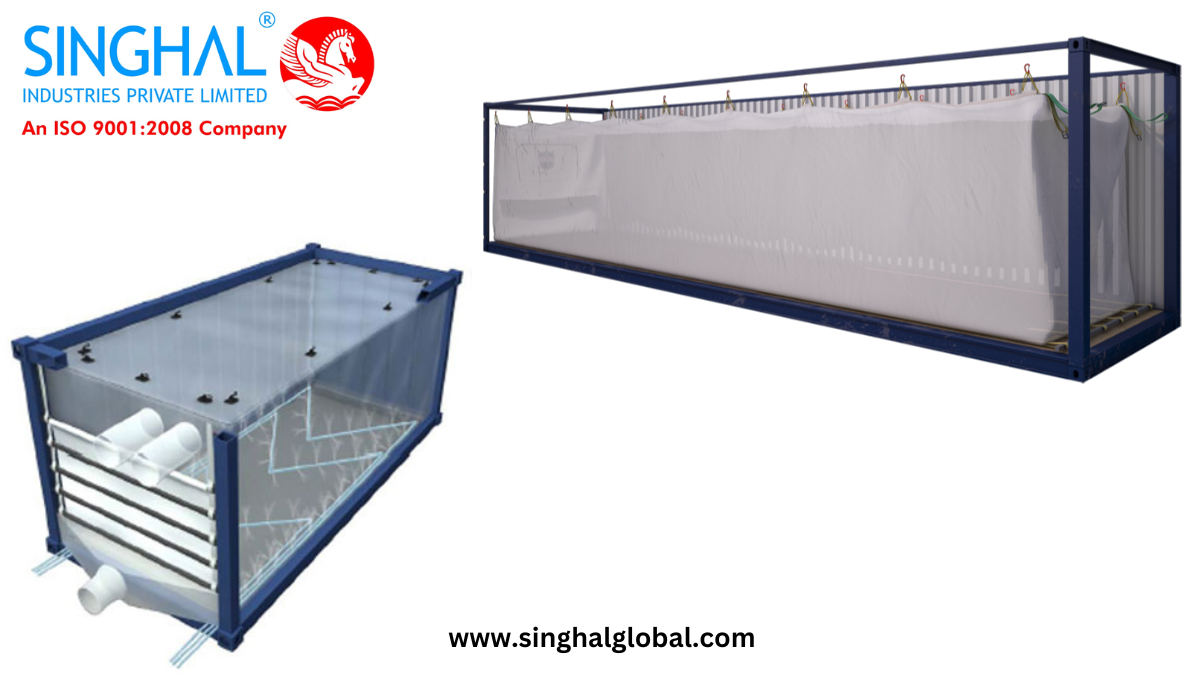

What are Container Liners?

Container liners, often referred to as liner bags, are flexible bags or sheets made from various materials, typically polyethylene or polypropylene. They are used to line the interior of shipping containers to create a protective barrier for bulk products such as grains, powders, and chemicals. By providing this additional layer of protection, container liners enhance the safety and integrity of the cargo during transport.

Key Benefits of Container Liners

-

Moisture Protection: One of the primary functions of container liners is to safeguard cargo from moisture. They are designed to be moisture-resistant, helping to prevent mold, mildew, and spoilage of sensitive materials.

-

Contamination Prevention: Container liners create a physical barrier that protects cargo from dust, dirt, and contaminants that may be present in the container. This is particularly important for food and pharmaceutical products.

-

Cost Efficiency: Using container liners can reduce the need for costly cleaning and fumigation processes for shipping containers. By protecting the cargo, businesses can save on potential losses due to damage.

-

Easy Handling: Liner bag container are designed for easy loading and unloading. They often come with features such as top openings and bottom discharge options that streamline the handling process.

-

Versatile Applications: Container liners can be used for a wide range of products, including food grains, chemicals, and minerals, making them a versatile choice for different industries.

Applications of Container Liners

1. Agriculture

In the agricultural sector, container liners are widely used to transport grains, seeds, and fertilizers. Their moisture-resistant properties help maintain the quality of these products during transport, ensuring that they reach their destination in optimal condition.

2. Food Industry

The food industry relies on container liners to package and transport dry ingredients such as flour, sugar, and spices. These liners help prevent contamination and spoilage, ensuring food safety and compliance with health regulations.

3. Chemicals

Container liners are essential in the chemical industry for transporting powders, granules, and liquid chemicals. They provide a protective barrier that reduces the risk of chemical reactions and contamination during transport.

4. Mining and Minerals

In the mining sector, container liners are used for transporting minerals and bulk materials. Their robust construction helps withstand the rigors of transport, ensuring that the cargo remains secure and intact.

5. Retail and Consumer Goods

Many retailers use container liners for bulk products such as pet food, fertilizers, and other consumer goods. The liners help maintain product integrity and enhance the overall presentation of the cargo.

Sourcing Container Liners

When looking to purchase container liners, it is crucial to engage with reputable Container liners manufacturers. Here are some tips for sourcing these essential packaging solutions:

-

Quality Assurance: Choose manufacturers that adhere to industry standards and provide high-quality materials. Look for certifications indicating compliance with safety and quality regulations.

-

Customization Options: Many businesses require customized container liners to meet specific needs. Ensure that your supplier offers options for size, thickness, and printing.

-

Pricing: Understanding the pricing structure for container liners is vital for budgeting. Compare prices from different suppliers while considering the quality and features of the liners.

-

Customer Feedback: Research customer reviews and testimonials about the manufacturers you are considering. This can provide valuable insights into their reliability, product quality, and customer service.

-

Local Availability: Engaging with container liners manufacturers in your region can facilitate easier sourcing and timely delivery, leading to potential cost savings on transportation.

Summary

Container liners are vital in protecting bulk cargo during transportation, offering numerous advantages such as moisture protection, contamination prevention, and cost efficiency. Their versatile applications across various industries, including agriculture, food, chemicals, and retail, make them an essential packaging solution. When sourcing container liners, it’s important to engage with reputable container liners manufacturers and understand the pricing structure and customization options available. By considering these factors, businesses can make informed decisions that enhance their operational efficiency and protect their valuable cargo.

Frequently Asked Questions (FAQs)

1. What materials are commonly used for container liners?

Container liners are typically made from materials like polyethylene (PE) and polypropylene (PP). These materials are chosen for their durability, moisture resistance, and ability to provide a barrier against contaminants.

2. How are container liners installed in shipping containers?

Container liners are usually installed by placing them inside the container and securing them at the top. They often feature a top opening for filling and a bottom discharge option for easy unloading. The installation process is designed to be quick and efficient.

3. Can container liners be reused?

While some container liners are designed for single-use, others can be reused if they remain intact and clean. However, the level of reuse will depend on the type of material and the specific application. Always consult with the manufacturer for guidance on reuse.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News