Many people don't know what LPG Regulator is. Today we will talk about the overall structure of the LPG Regulator and its operation.

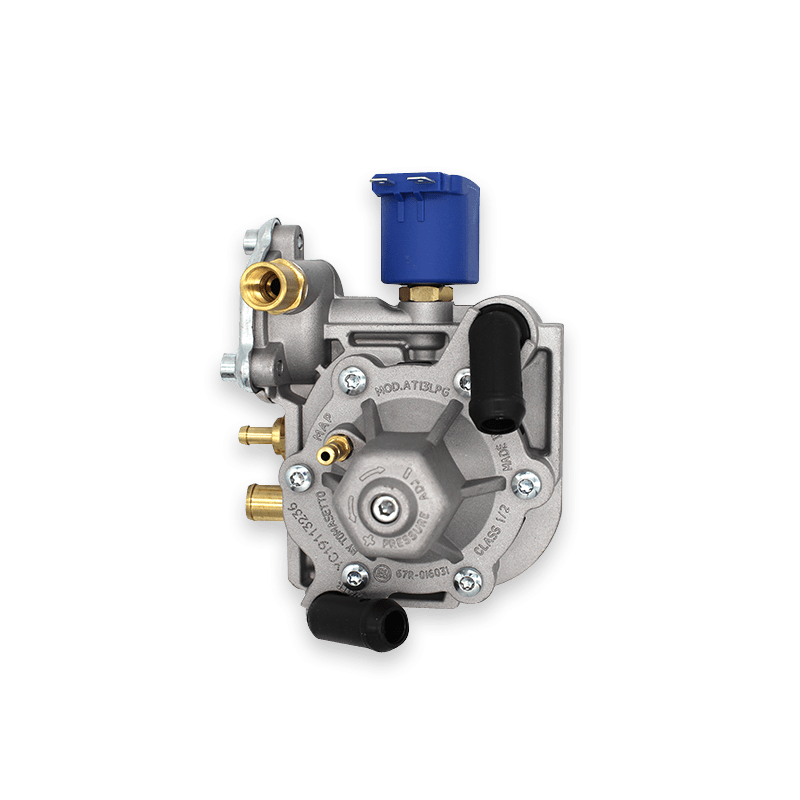

LPG Regulator includes the main valve body, exhaust nozzle, intake nozzle, pressure reducing valve, and connecting device. The pressure reducing valve is located on the upper part of the main valve body, the exhaust nozzle is located in the radial direction of the main valve body, and the intake nozzle is located on the main valve body. At the bottom of the air inlet, there is an ejector rod in the intake nozzle, and the crankshaft is installed horizontally in the main valve body. An eccentric cylinder is provided at the corresponding position above the ejector rod on the crankshaft. The clamping block connected and driven by the switch is composed of ejection springs arranged at the connection between the crankshaft and the knob switch. The clamping block is provided with a flange, and the flange is buckled in the groove provided in the knob switch, The clamping block can slide axially synchronously with the rotary switch.

LPG Regulator only needs to push the knob switch and relax it to complete the fixed connection between the regulator and the angle valve. Then turn the knob switch 90° to complete the valve clamping and gas conduction process without any auxiliary tools. It is widely used in industrial and civil gas fields.

For more details, please visit LPG CNG Injector .