PP Sheets: A Versatile Material for Modern Industrial Applications

Polypropylene (PP) sheets have become an essential material in a wide range of industries due to their durability, versatility, and cost-effectiveness. These sheets, made from polypropylene, a thermoplastic polymer, offer a host of benefits such as chemical resistance, flexibility, and strength. As industries evolve and require more specialized materials, PP sheets have emerged as a reliable and efficient solution for a variety of applications, from packaging and automotive to construction and medical industries. In this Pulkit Plastic Products, we’ll explore the properties, manufacturing processes, applications, and growing demand for PP sheets, particularly focusing on the role of PP sheet manufacturers and suppliers.

1. What Are PP Sheets?

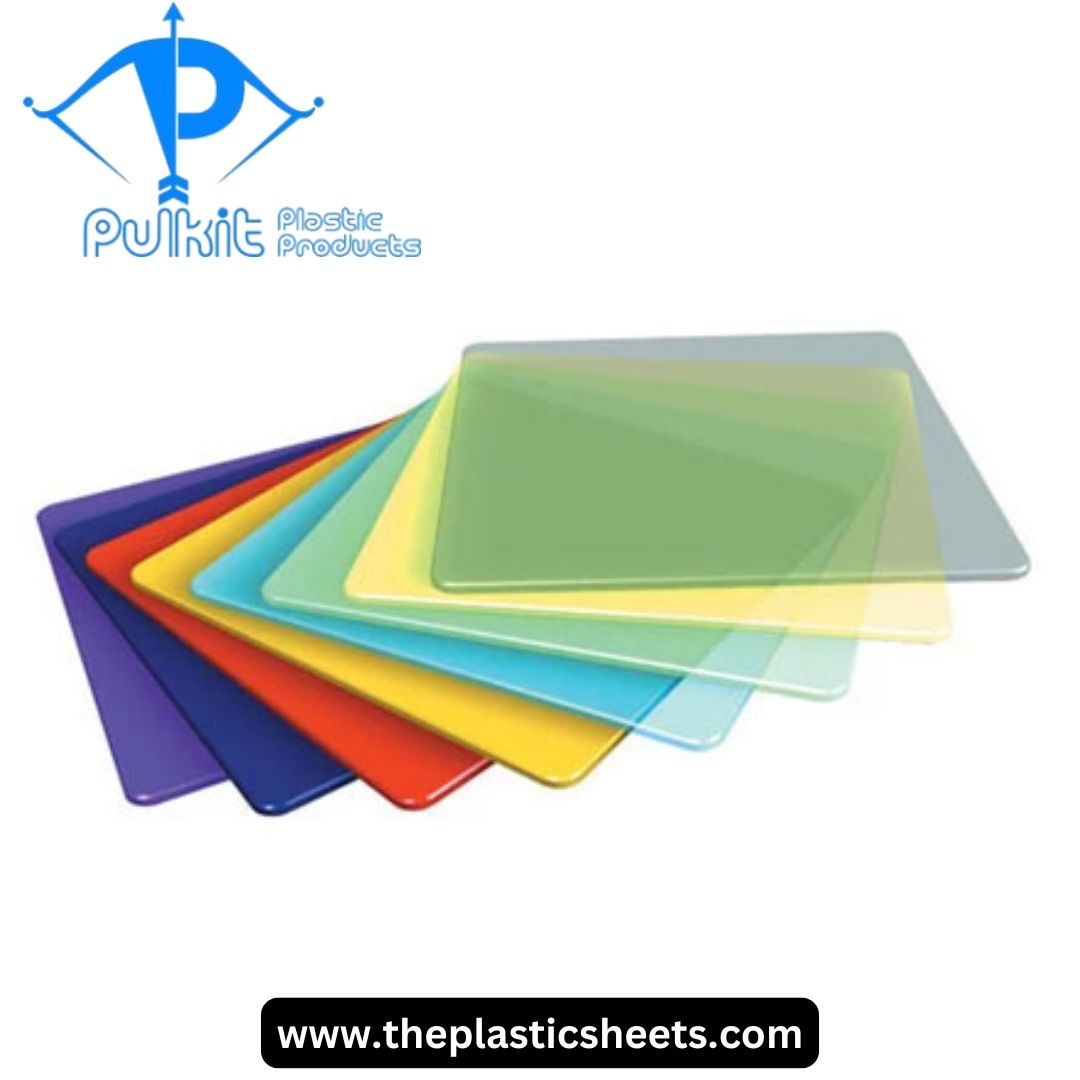

PP sheets are flat pieces of plastic made from polypropylene, a lightweight yet strong thermoplastic polymer. Polypropylene is known for its excellent resistance to moisture, chemicals, and fatigue, which makes PP sheets highly suitable for environments where these properties are crucial. Available in a range of thicknesses, colors, and sizes, these sheets are commonly used in industries where durability and resistance to harsh conditions are necessary.

PP sheets are manufactured through a process called extrusion, where melted polypropylene resin is forced through a die to form a continuous flat sheet. This manufacturing process allows for the production of sheets in varying dimensions, depending on the intended use. PP sheet manufacturers play a critical role in producing high-quality sheets tailored to meet specific industrial requirements. In addition to being durable, PP sheets are also lightweight and easy to handle, making them an ideal choice for various applications, from packaging to automotive components.

2. Key Properties of PP Sheets

PP sheets are favored by numerous industries due to their unique set of properties. One of the most important attributes of polypropylene sheets is their resistance to chemicals. This makes them suitable for environments where exposure to aggressive chemicals, such as acids or solvents, is common. Additionally, PP Sheet Manufacturer are resistant to moisture, making them an excellent choice for applications involving contact with water or humid environments.

Another key property is the sheet's flexibility and fatigue resistance. Unlike many other plastics, polypropylene can endure repeated bending and flexing without cracking or breaking. This makes it highly suitable for applications that involve regular movement or stress, such as in packaging or automotive components. Furthermore, PP sheets are resistant to UV rays, which helps prevent degradation when used outdoors or in environments exposed to sunlight. PP sheet manufacturers often design sheets with added UV stabilizers to enhance their outdoor performance, ensuring they maintain their strength and appearance over time.

3. PP Sheets in the Packaging Industry

The packaging industry is one of the largest users of PP sheets, thanks to their lightweight, durability, and ease of fabrication. PP sheets are commonly used in the production of containers, boxes, trays, and other packaging products. Due to their chemical resistance, they are widely used in food packaging, ensuring that the contents remain safe and uncontaminated. The ability of PP sheets to withstand moisture also makes them ideal for packaging products that need to be protected from humidity.

PP sheet suppliers often offer sheets in various grades tailored for specific packaging needs. For example, food-grade PP sheets are designed to meet stringent safety standards for packaging consumables. These sheets are also recyclable, contributing to the growing demand for sustainable packaging solutions. With the global focus on reducing plastic waste, PP sheet manufacturers are increasingly developing eco-friendly packaging solutions by producing sheets that are both reusable and recyclable, aligning with modern environmental standards.

4. Applications of PP Sheets in the Automotive Industry

PP sheets have become a key material in the automotive industry due to their lightweight nature, which contributes to fuel efficiency. Components made from PP sheets, such as interior panels, under-the-hood parts, and battery cases, help reduce the overall weight of vehicles without compromising strength. PP sheets can also be thermoformed, a process that involves heating the sheet and shaping it into various automotive parts.

The ability to withstand high temperatures and resist chemical exposure makes PP sheets ideal for automotive applications, where components often encounter oil, fuel, and heat. PP sheet suppliers work closely with automotive manufacturers to ensure that the materials used meet the specific requirements of the industry. Additionally, PP sheets offer cost savings over traditional materials such as metal, further driving their adoption in automotive manufacturing.

5. The Role of PP Sheets in Construction

In the construction industry, PP sheets are used for applications where durability and weather resistance are essential. One popular use of PP sheets is as protective barriers during construction projects. The sheets can be easily cut and installed as protection against dust, moisture, and debris, helping to keep construction sites clean and safe.

The PP Sheet Manufacturers are also used in formwork for concrete casting, providing a reusable and flexible alternative to traditional wooden or metal formwork. The smooth surface of PP sheets ensures that the finished concrete has a clean and consistent appearance. Moreover, due to their chemical resistance, these sheets are often used in projects where contact with corrosive substances or harsh weather conditions is expected. As a result, PP sheet suppliers in the construction sector continue to see strong demand for their products.

6. Medical Applications of PP Sheets

The medical industry requires materials that are not only durable but also hygienic and resistant to chemicals and bacteria. PP sheets meet these criteria, making them a popular choice for various medical applications. These sheets are used to produce medical trays, sterilization containers, and storage bins, ensuring that medical instruments and products are kept in a clean and safe environment.

PP sheets are also used in the production of disposable medical equipment due to their cost-effectiveness and ease of sterilization. The sheets can be easily formed into various shapes and sizes, allowing manufacturers to create customized solutions for medical facilities. PP sheet manufacturers often work closely with healthcare providers to develop products that meet the stringent requirements of the medical industry, including biocompatibility and resistance to sterilization processes like autoclaving.

7. Sustainability and Environmental Impact of PP Sheets

As the world becomes more conscious of environmental sustainability, industries are increasingly turning to materials that have a reduced environmental impact. PP sheets are considered more environmentally friendly than many other plastics because polypropylene is recyclable. After use, PP sheets can be melted down and reprocessed into new products, reducing waste and minimizing the need for virgin materials.

PP sheet manufacturers are now focusing on producing recyclable sheets that meet the growing demand for sustainable solutions in industries such as packaging, automotive, and construction. The lightweight nature of PP sheets also contributes to their environmental benefits, as it reduces transportation costs and carbon emissions during shipping. Additionally, some manufacturers are incorporating recycled polypropylene into their production processes, further enhancing the sustainability of their products.

8. Conclusion: The Future of PP Sheets

In conclusion, PP Sheet Suppliers have proven to be a highly versatile and durable material that is increasingly in demand across a variety of industries. Their unique properties, such as chemical resistance, flexibility, and recyclability, make them suitable for applications ranging from packaging and automotive to construction and medical industries. With an ever-growing focus on sustainability, PP sheet manufacturers are adapting to meet the needs of eco-conscious industries by developing recyclable and reusable products.

As industries continue to evolve and seek more cost-effective and environmentally friendly materials, the role of PP sheets is expected to expand even further. With innovations in manufacturing and a growing emphasis on sustainability, PP sheets will continue to be a key player in the future of industrial materials.

Frequently Asked Questions (FAQs)

What are the key advantages of using PP sheets in industrial applications?

PP sheets offer chemical resistance, flexibility, durability, and lightweight properties, making them ideal for various industrial uses. Additionally, they are cost-effective and recyclable, making them a sustainable choice.

Who are the major PP sheet manufacturers?

Many global and regional PP sheet manufacturers produce high-quality polypropylene sheets. In India, a growing number of manufacturers are producing PP sheets to meet domestic and international demand, ensuring a competitive market.

Can PP sheets be recycled?

Yes, PP sheets are recyclable. They can be melted down and reprocessed into new products, making them an environmentally friendly choice for industries looking to reduce waste.

What industries commonly use PP sheets?

PP sheets are used in various industries, including packaging, automotive, construction, and medical sectors, due to their versatility, strength, and resistance to chemicals and moisture.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News