Corrugated Box Making Machines: Revolutionizing Packaging

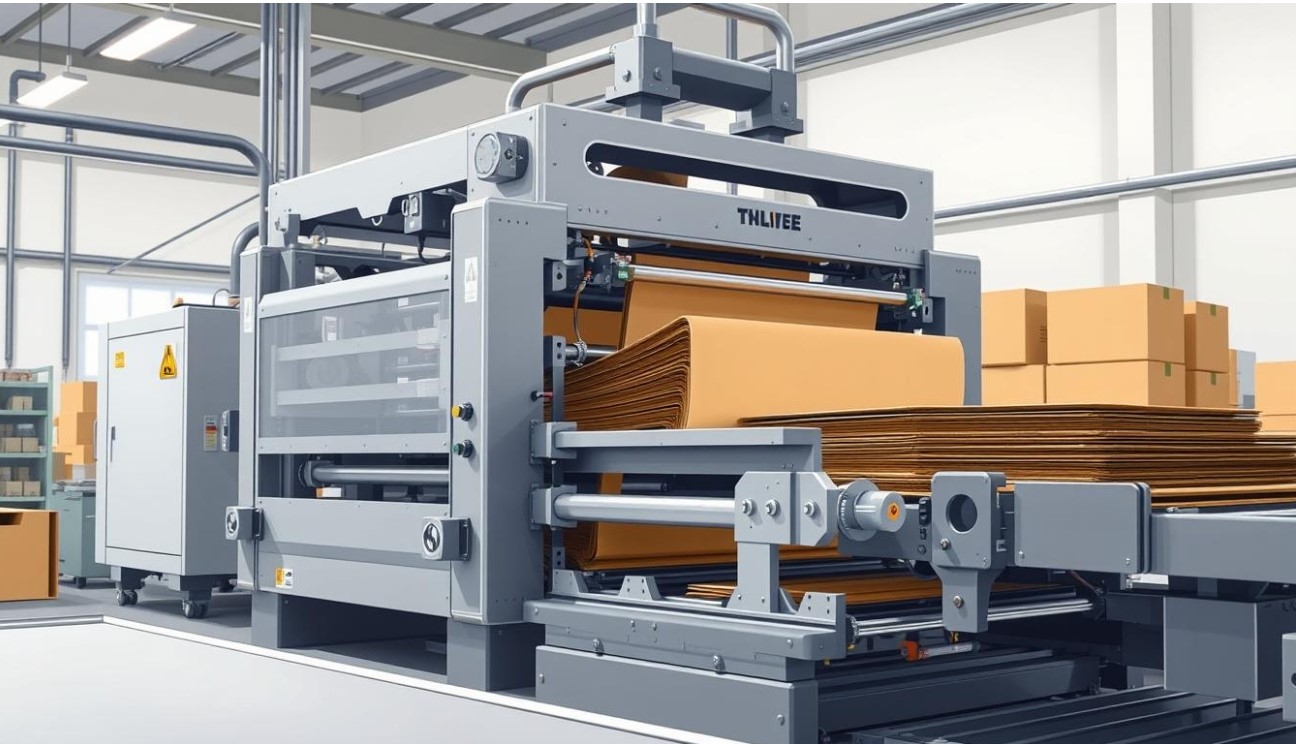

Corrugated box making machines have become an essential asset in the packaging industry. As the demand for sustainable and durable packaging continues to rise, businesses are increasingly adopting these machines to enhance production efficiency while meeting environmental and economic demands. This article delves into the importance, functions, types, and benefits of Corrugated Box Making Machine in modern packaging.

Introduction to Corrugated Box Making Machines

Corrugated boxes are widely used for shipping and storage due to their strength, lightweight properties, and recyclability. A corrugated box is composed of three layers: an inside liner, an outside liner, and a fluted layer in between. The fluted layer provides cushioning and enhances the box’s durability. To produce these boxes at scale, corrugated box making machines are indispensable. They automate the manufacturing process, providing consistent quality and reducing production time.

Key Functions of Corrugated Box Making Machines

Corrugated box making machines perform various functions depending on the model and its features. Some key processes include:

1. Paperboard Cutting: These machines are equipped with high-precision cutters that ensure the cardboard is cut to the desired size.

2. Corrugation: The heart of the machine involves forming the flutes, where the paperboard passes through heated rollers that form the wave-like structure (fluting), giving the box its rigidity.

3. Gluing and Bonding: After forming the corrugation, the machine applies glue to bond the fluted paper with the liners. The bonding ensures the corrugated structure remains intact and maintains its strength.

4. Slotting and Scoring: Machines also perform slotting, which is the cutting of slots on the box to allow for folding. Scoring creates crease lines for easy and precise folding.

5. Folding and Finishing: Finally, the machine folds the cut and glued board into its final box shape, ensuring uniformity across production batches.

Types of Corrugated Box Making Machines

There are different types of corrugated box making machines available based on the production requirements of the business:

1. Automatic Corrugated Box Making Machines: These are fully automated systems that require minimal human intervention. They are ideal for large-scale production as they increase efficiency and reduce labor costs.

2. Semi-Automatic Machines: These machines combine both manual and automatic operations. While they may require more operator involvement than fully automated systems, they still significantly improve production speed compared to manual methods.

3. Flexo Folder Gluers: These machines can print directly on corrugated boxes and perform folding and gluing simultaneously. Flexo folder gluers are popular for businesses that require custom printed boxes.

4. Die-Cutting Machines: For businesses that require boxes of non-standard shapes or designs, die-cutting machines can be used to create custom shapes while maintaining the integrity of the corrugated material.

Benefits of Corrugated Box Making Machines

Corrugated box making machines offer a wide range of benefits to businesses in the packaging industry, including:

1. Increased Efficiency: Automation in box-making machines speeds up the production process and reduces the likelihood of errors, helping businesses meet tight deadlines and high-demand periods.

2. Cost Savings: While the initial investment in these machines may be significant, the long-term cost savings are notable. By automating production, businesses can reduce labor costs and minimize material waste.

3. Consistency in Quality: One of the main challenges of manual production is inconsistency in quality. Corrugated box making machines ensure uniformity across batches, which is crucial for businesses that prioritize high-quality packaging.

4. Environmental Benefits: As corrugated boxes are recyclable, using these machines aligns with the growing trend towards sustainability. Additionally, some modern machines are energy-efficient and reduce the carbon footprint of the manufacturing process.

5. Customization: Modern machines allow for customization in terms of box size, shape, and printing. This flexibility is particularly important for businesses that require branded or specialized packaging.

6. Scalability: As businesses grow, their packaging needs increase. Corrugated box making machines can easily scale production, ensuring that companies can meet the rising demand for their products without compromising on packaging quality.

The Future of Corrugated Box Making Machines

As industries continue to innovate, the future of corrugated box making machines will likely involve even greater levels of automation and efficiency. Technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are expected to play a significant role in improving machine performance. AI could enable predictive maintenance, reducing machine downtime and improving overall productivity. Furthermore, advancements in eco-friendly materials and energy-efficient machinery will continue to make the packaging process more sustainable.

Conclusion

Corrugated box making machines have transformed the packaging industry by enhancing production speed, reducing costs, and ensuring consistency in quality. As businesses strive to meet consumer demands for sustainable and reliable packaging, these machines will continue to play a crucial role. Whether a company requires mass production or customized packaging solutions, corrugated box making machines provide the versatility and efficiency needed to stay competitive in today’s market. With continuous innovation in automation and eco-friendly practices, the future of these machines looks bright, promising even greater advancements in the years to come.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News