The Essential Guide to Geomembrane Suppliers: Choosing the Right Partner for Your Projects

Geomembranes are crucial components in various construction and environmental applications, providing an effective barrier against fluid migration. As industries focus on sustainability Pulkit Plastic Products and environmental protection, the demand for high-quality geomembranes has surged. This article explores the role of Geomembrane Suppliers In India, key considerations when choosing a supplier, and answers to frequently asked questions.

Understanding Geomembranes

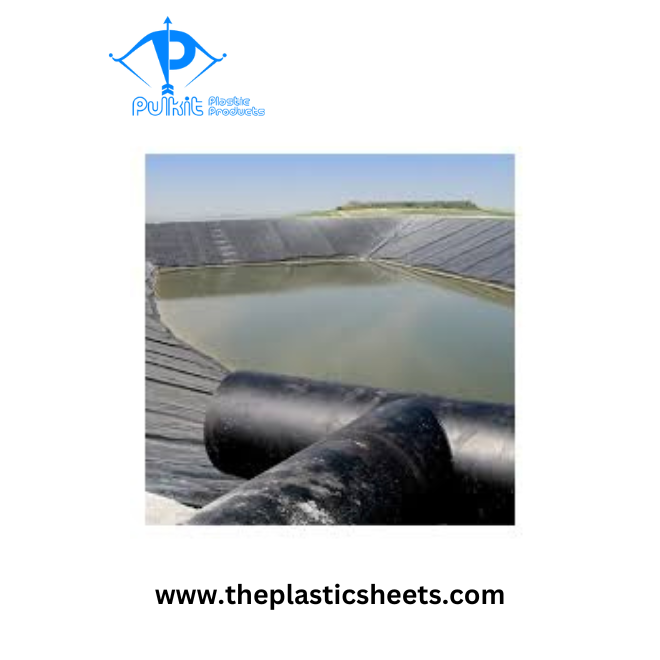

Geomembranes are impermeable membranes made from synthetic materials, commonly used to contain liquids or gases. They serve several critical functions, including:

- Containment: Preventing the leakage of hazardous materials in landfills, mining operations, and wastewater treatment facilities.

- Separation: Isolating different materials in construction projects to maintain structural integrity.

- Environmental Protection: Safeguarding soil and groundwater from contamination by providing effective barriers.

Geomembranes are widely used in various sectors, including:

- Landfills: To contain leachate and prevent soil contamination.

- Mining: For the safe storage of tailings and other hazardous materials.

- Agriculture: In the construction of ponds and irrigation systems to retain water.

- Water Reservoirs: To minimize evaporation and maintain water quality.

The Role of Geomembrane Suppliers

Geomembrane suppliers play a vital role in providing the materials necessary for these applications. They not only manufacture geomembranes but also offer essential services that can significantly impact the success of a project.

Key Functions of Geomembrane Suppliers:

-

Product Variety: Suppliers typically offer a range of geomembrane products, including different thicknesses, materials (such as HDPE, LLDPE, PVC), and custom solutions tailored to specific project requirements.

-

Technical Support: A good supplier provides technical expertise, helping clients choose the right geomembrane for their specific applications. This may include guidance on installation techniques, environmental considerations, and regulatory compliance.

-

Quality Assurance: Reputable suppliers ensure that their products meet industry standards and certifications, such as ASTM and GRI, which guarantee the performance and durability of geomembranes in various applications.

-

Logistics and Delivery: Efficient suppliers offer timely delivery services and logistics support to ensure that materials arrive on-site when needed, preventing project delays.

-

Installation Services: Some suppliers provide installation services or work with certified contractors to ensure that geomembranes are correctly installed, maximizing their effectiveness.

Choosing the Right Geomembrane Supplier

Selecting the right Geomembrane Price In India is critical for the success of any project. Here are some key factors to consider:

1. Experience and Reputation

Look for suppliers with a proven track record in the industry. Experienced suppliers are more likely to understand the complexities of different applications and provide valuable insights. Additionally, consider their reputation among previous clients. Online reviews and testimonials can provide insight into their reliability and quality of service.

2. Product Range

Choose a supplier that offers a comprehensive range of geomembrane products. This ensures you can find the right material for your specific needs. A diverse product line also indicates that the supplier is knowledgeable about various applications and can recommend suitable options.

3. Quality Standards

Ensure the supplier adheres to industry standards and certifications. High-quality geomembranes should meet relevant specifications to ensure durability and effectiveness. Request documentation of certifications to verify the quality of their products.

4. Technical Support and Consultation

A supplier that offers technical support and consultation can be a valuable partner. Look for suppliers that are willing to discuss your project’s specific requirements and provide expert advice on material selection, installation techniques, and regulatory compliance.

5. Pricing and Availability

While cost should not be the sole factor in your decision, it is essential to consider pricing. Request quotes from multiple suppliers to compare costs. Also, ensure that the supplier can meet your project timelines with timely delivery.

6. Customer Service

Evaluate the supplier’s customer service approach. A responsive and helpful team can make a significant difference in resolving any issues or concerns during the procurement process. Good communication is crucial for a successful partnership.

Conclusion

Choosing the right geomembrane supplier is crucial for the success of your project. By considering factors such as experience, product range, quality standards, and customer service, you can find a reliable partner that meets your needs. Understanding the role of Geotextiles And Geomembranes in various applications and the benefits they provide will help you make informed decisions. With the right supplier, you can ensure the durability, effectiveness, and environmental protection required for your projects.

Frequently Asked Questions (FAQ)

1. What are the different types of geomembranes available?

There are several types of geomembranes, with the most common being:

- High-Density Polyethylene (HDPE): Known for its strength and chemical resistance, making it ideal for landfills and industrial applications.

- Linear Low-Density Polyethylene (LLDPE): Offers flexibility and durability, often used in agriculture and ponds.

- Polyvinyl Chloride (PVC): Flexible and easy to install, used in various applications, including water containment.

- Ethylene Propylene Diene Monomer (EPDM): Known for its weather resistance, often used in roofing and pond liners.

2. How do I know which geomembrane is suitable for my project?

Choosing the right geomembrane depends on several factors, including the application, environmental conditions, and regulatory requirements. Consulting with your geomembrane supplier can help you assess these factors and determine the best option for your specific needs.

3. Can geomembranes be recycled?

Many geomembranes, particularly those made from HDPE, are recyclable. However, the recycling process may vary based on local facilities and regulations. Check with your supplier for information on recycling options and sustainable disposal methods for geomembranes.

4. What is the typical lifespan of geomembranes?

The lifespan of geomembranes varies depending on the material, installation quality, and environmental conditions. Generally, high-quality geomembranes can last anywhere from 20 to 30 years or more when installed and maintained correctly. Regular inspections and maintenance can help extend their service life.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News