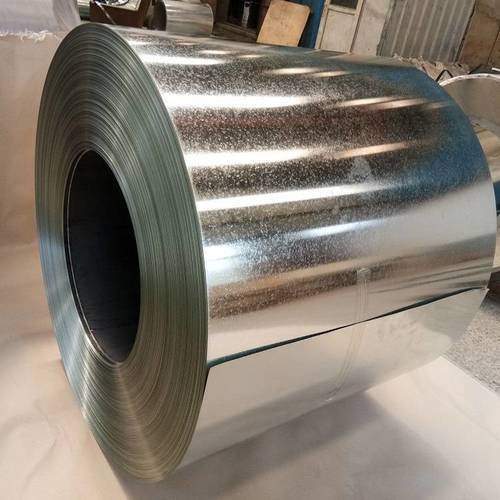

Galvanized steel coil: characteristics and applications

Galvanized steel coil is a steel product with a layer of zinc metal coated on the surface of the steel plate. It has many excellent characteristics and wide applications. The following is a detailed introduction to galvanized steel coil, including its characteristics, applications, specifications, production process and price.

- Production process of galvanized steel coil

The production process of galvanized steel coil mainly includes the following steps:

Steel coil pickling: remove oxides, oil stains and rust on the steel surface to ensure the galvanizing effect.

Cleaning: rinse the acid, chloride ions and other harmful substances remaining on the surface of the steel coil after pickling.

Pretreatment: form a protective film on the steel surface to increase the bonding force between the steel coil and the zinc liquid and improve the quality of the coating.

Baking: make the protective film on the surface of the steel coil completely dry, which is convenient for the subsequent zinc dipping process.

Zinc dipping: put the baked steel coil into the molten zinc liquid for dipping to form a zinc layer.

Cooling: make the zinc layer on the surface of the steel coil solidify quickly to ensure the quality of the coating.

Coil: The galvanized steel coil is rewound and quality inspected. - Characteristics of galvanized steel coil

Excellent anti-corrosion performance: The zinc layer on the surface of the galvanized steel coil can effectively isolate the steel plate from direct contact with the external environment, prevent the steel plate from being oxidized and corroded, and thus extend the service life of the steel. Even under harsh environmental conditions, such as high humidity and salt, it can maintain good anti-corrosion performance.

Easy processing: The galvanized steel coil has good processing performance and can be punched, cut, bent, drilled and undergo other processing operations. Its surface is smooth and uniform in texture, reducing the occurrence of burrs and rust after processing, which minimizes the need for post-processing.

Environmentally friendly and pollution-free: The galvanized steel coil does not produce harmful substances, noise or waste during the production process. At the same time, its surface does not need to be painted, thus avoiding the pollution of the environment by paint.

High strength: The galvanized steel coil exhibits high strength, hardness, and good bearing capacity, making it suitable for various structures requiring high-strength support.

Economical: The production cost of galvanized steel coil is low, and the service life is long, which can reduce maintenance and replacement costs. Simultaneously, it is easy to process and install, improving work efficiency and reducing project costs. - Application of galvanized steel coils

Galvanized steel coils are widely used in many fields due to their excellent performance, mainly including:

Construction field: used for parts in building structures, such as beams, columns, purlins, etc.; as well as building roofs, walls and other parts to protect building materials from atmospheric and water corrosion.

Automotive industry: used for body, chassis, doors and other parts in automobile manufacturing to improve the safety and reliability of automobiles.

Home appliance industry: used to produce the shells of home appliances such as refrigerators, washing machines, air conditioners, etc., to enhance the beauty and durability of products.

Communication equipment: also used in the field of communication equipment, such as base stations, towers, antennas, etc., to ensure the stable operation of equipment.

Other fields: such as food processing, agricultural machinery, shipbuilding, furniture manufacturing, etc., galvanized steel coils play an important role. - Common specifications of galvanized steel coils

The specifications of galvanized steel coils mainly include thickness, width and material. In terms of thickness, the common specifications of galvanized steel coils are mainly concentrated between 0.18mm and 0.3mm, among which 0.2mm is one of the more common and commonly used specifications. Different industries and uses also have different requirements for the width and material of galvanized steel coils. - The price of galvanized steel coils

The price of galvanized steel coils is affected by many factors, including raw material costs, production processes, market demand, supply conditions, etc. Therefore, the prices of galvanized steel coils of different times, brands, and specifications will vary. Generally speaking, the prices of galvanized steel coils produced by large steel mills are relatively stable, while the prices of small steel mills or traders may be greatly affected by market fluctuations.

In order to obtain specific galvanized steel coil price information, it is recommended to contact the relevant steel mills or traders directly for consultation. Wanzhi Steel is a well-known manufacturer of coating and plating products in China. You can contact Wanzhi for details about galvanized steel, aluminum-zinc steel, ppgi steel, and ppgl steel.

In summary, galvanized steel coils are widely used in many fields such as construction, automobiles, and home appliances due to their excellent anti-corrosion performance, convenient processing, environmental protection, high strength, and economy. With the development of the economy and the advancement of science and technology, the application prospects of galvanized steel coils will be broader.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News