-

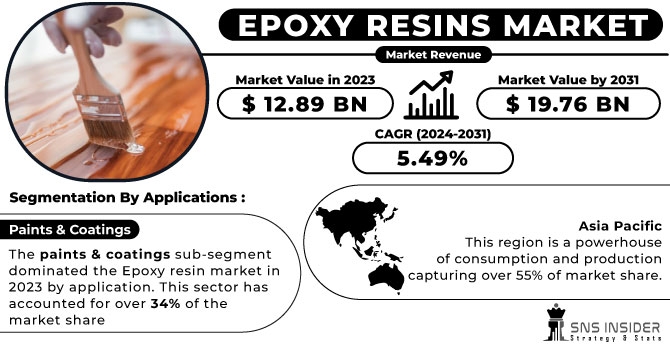

The epoxy resins market is poised for remarkable expansion, with its value projected to increase from USD 12.89 billion in 2023 to an outstanding USD 19.76 billion by 2031. This growth, represented by a CAGR of 5.49% from 2024 to 2031, is driven by rising demand across various industries and the superior qualities of epoxy resins that make them crucial in a wide array of applications.

-

epoxy resins market is experiencing significant growth, with its valuation expected to rise from USD 12.89 billion in 2023 to an impressive USD 19.76 billion by 2031. This anticipated expansion represents a compound annual growth rate (CAGR) of 5.49% over the forecast period from 2024 to 2031. The market's upward trajectory is driven by a convergence of factors, including increasing demand across various industries and the exceptional properties of epoxy resins that make them indispensable in numerous applications.

Market Dynamics

Epoxy resins are valued for their outstanding mechanical properties, chemical resistance, and strong adhesive qualities. These characteristics have led to their widespread adoption in multiple sectors, most notably in construction, automotive, aerospace, electronics, and marine industries.

Construction Industry: One of the primary drivers of the epoxy resins market is the construction industry. Epoxy resins are crucial in high-performance applications such as civil infrastructure projects, buildings, and flooring. Their exceptional strength and durability make them ideal for use in environments that demand resilience and longevity. In particular, epoxy resins are extensively used in coatings, adhesives, and sealants within the construction sector, providing enhanced structural integrity and longevity to buildings and infrastructure.

Automotive and Transportation: The automotive industry is another significant contributor to the growth of the epoxy resins market. Epoxy resins are used in the production of lightweight composite materials that help improve fuel efficiency and reduce emissions in vehicles. Their application in adhesives and sealants also contributes to vehicle durability and safety.

Aerospace: In the aerospace sector, epoxy resins are utilized in the manufacture of composite materials for aircraft components. These materials offer high strength-to-weight ratios, which are essential for the performance and efficiency of modern aircraft. The increasing production of commercial and military aircraft is expected to drive the demand for epoxy resins in this industry.

Electronics: The electronics industry relies on epoxy resins for encapsulation and protection of delicate components. The resins provide excellent insulation and protection against moisture and environmental contaminants, ensuring the reliability and longevity of electronic devices. With the growing demand for consumer electronics and advancements in technology, the use of epoxy resins in this sector is projected to rise.

Segment Analysis

The epoxy resins market is segmented based on physical form, raw materials, application, end-use industry, and region.

Physical Form:

· Solid: Used primarily in powder coatings and molding compounds.

· Liquid: Preferred for applications requiring impregnation and high mechanical strength.

· Solution: Employed in applications needing specific viscosity and ease of application.

Raw Materials:

· BADGE (Bisphenol A Diglycidyl Ether): Widely used due to its versatility and excellent performance characteristics.

· BFDGE (Bisphenol F Diglycidyl Ether): Known for its low viscosity and high chemical resistance.

· Novolac: Offers superior thermal and chemical resistance.

· Aliphatic: Used for its flexibility and toughness.

· Glycidylamine: Preferred for high-performance applications due to its high glass transition temperature.

· Others: Includes various other specialized resins tailored for specific applications.

Application:

· Paints & Coatings: Epoxy resins are essential in protective coatings, providing durability and resistance to corrosion.

· Adhesives & Sealants: Widely used in construction and automotive industries for their strong bonding capabilities.

· Composites: Increasingly used in aerospace, automotive, and wind energy sectors for lightweight and high-strength materials.

· Electronic Encapsulation: Ensures the protection and reliability of electronic components.

· Others: Includes various niche applications across different industries.

End-Use Industry:

· Building & Construction: The largest segment due to extensive use in coatings, adhesives, and sealants.

· Transportation: High demand from automotive and aerospace industries for lightweight and durable materials.

· General Industrial: Includes machinery, equipment, and other industrial applications.

· Consumer Goods: Increasing use in durable and aesthetically pleasing consumer products.

· Wind Energy: Growing application in the production of wind turbine blades.

· Aerospace: Demand for high-performance composites for aircraft components.

· Marine: Usage in protective coatings and composite materials for boats and ships.

Regional Analysis

The epoxy resins market is analyzed across several key regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

North America: The market in North America is driven by advancements in technology and significant demand from the aerospace and automotive industries. The presence of major manufacturers and increasing investments in infrastructure projects further fuel the growth.

Europe: Europe’s market is characterized by strong demand from the automotive sector, especially in Germany and the UK. Stringent environmental regulations also drive the adoption of eco-friendly epoxy resins in various applications.

Asia-Pacific: The Asia-Pacific region holds the largest market share, with China and India being major contributors. Rapid industrialization, urbanization, and investments in infrastructure projects are key factors driving the demand for epoxy resins in this region. The growing electronics industry in countries like Japan and South Korea also significantly contributes to market growth.

Latin America: The market in Latin America is driven by increasing construction activities and automotive production in countries such as Brazil and Mexico.

Middle East & Africa: The demand for epoxy resins in this region is primarily driven by infrastructure development and investments in the oil and gas industry.

Technological Advancements and Sustainability

Technological advancements in the production and application of epoxy resins are expected to drive market growth further. Innovations in raw materials, formulation techniques, and curing processes are enhancing the performance and sustainability of epoxy resins.

Sustainability is becoming a crucial factor in the epoxy resins market. Manufacturers are focusing on developing bio-based and environmentally friendly epoxy resins to meet the growing demand for sustainable solutions. These eco-friendly resins offer similar performance characteristics to traditional resins while reducing the environmental impact.

Conclusion

The epoxy resins market is set for substantial growth over the forecast period, driven by increasing demand across various industries, technological advancements, and a shift towards sustainable solutions. The market’s expansion from USD 12.89 billion in 2023 to USD 19.76 billion by 2031 reflects the critical role epoxy resins play in modern industrial applications. As industries continue to evolve and seek high-performance materials, epoxy resins will remain at the forefront of innovation and development.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

Read Related Reports:

Cellulosic Fire Protection Intumescent Coatings Market

Hybrid Sealants and Adhesives Market

Organosilicon Polymers (Polysiloxane) Market

Epoxy Resins MarketCOVID-19 Impact & Estimations Report 2024-2031