Crafting Success: Trends and Innovations in the Metal Stamping Industry

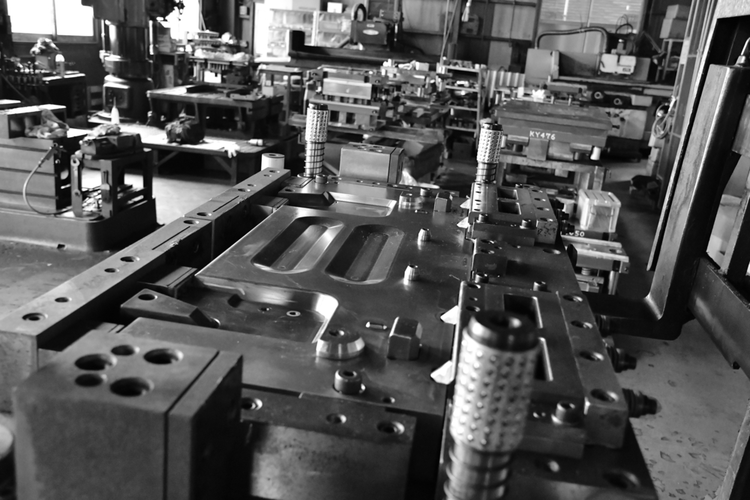

Placing flat sheet metal in either coil or blank form into a stamping press, where a tool and die surface mold the metal into a particular shape, is the process of stamping, sometimes called pressing.

A range of sheet-metal forming manufacturing techniques, including coining, blanking, embossing, bending, flanging, and punching with a machine press or stamping press, are included in the process of stamping. This could happen in a single step, where each press stroke forms the required shape on the sheet metal component, or it could happen in multiple steps.

In the ever-evolving metal stamping industry, staying abreast of emerging trends and innovations is paramount for sustained success.

Market Drivers

The Metal Stamping Market demand industry continues to be driven by a multitude of factors, including the increasing demand for lightweight and durable components across various sectors. Advancements in material science, coupled with growing environmental concerns, are influencing the adoption of sustainable stamping practices. Furthermore, the rise of electric vehicles and renewable energy technologies is driving innovation in metal stamping processes to meet evolving industry requirements.

The Metal Stamping Market is estimated to be valued at USD 222.14 Bn in 2024 and is expected to reach USD 290.36 Bn by 2031, growing at a compound annual growth rate (CAGR) of 3.9% from 2024 to 2031.

PEST Analysis

A PEST analysis provides valuable insights into the external factors influencing the metal stamping industry. Political stability and trade policies impact the flow of raw materials and finished products, affecting market dynamics. Economic factors such as inflation rates and consumer purchasing power influence market demand and investment decisions. Social trends towards automation and digitalization are reshaping manufacturing processes, while technological advancements drive innovation and competitiveness in the industry.

SWOT Analysis

Conducting a SWOT analysis reveals the industry's inherent strengths, weaknesses, opportunities, and threats. Strengths lie in the precision and efficiency offered by metal stamping processes, enabling the production of complex components with high accuracy. However, weaknesses such as reliance on skilled labor and susceptibility to market fluctuations pose challenges. Opportunities abound in emerging markets and the development of advanced materials and technologies, while threats include intense competition and regulatory compliance issues.

Segment Analysis

Segment analysis uncovers distinct categories within the metal stamping industry based on factors such as material type, technology, end-user industry, and geographic region. Different materials such as steel, aluminum, and alloys cater to diverse application requirements, while advancements in stamping technologies offer enhanced capabilities and efficiency. Automotive, aerospace, electronics, and consumer goods are among the key end-user segments driving demand for metal stamping solutions.

Get more insights on Metal Stamping Market

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News