Elevate Aesthetics: Textured ABS Sheets

In the realm of materials used in design and manufacturing, ABS (Acrylonitrile Butadiene Styrene) sheets have carved a niche for themselves, especially those with textured surfaces. These sheets are a testament to how material innovation can significantly impact aesthetics and functionality. Textured ABS sheets offer a unique blend of durability, versatility, and visual appeal, making them a preferred choice across various industries.

Understanding ABS Sheets

ABS sheets are thermoplastic materials known for their strength, rigidity, and resistance to impact. The composition of ABS involves three main components: acrylonitrile, butadiene, and styrene. This combination results in a material that is not only tough and durable but also easy to mold and shape, which is why it is extensively used in manufacturing processes.

The Aesthetic Advantage of Textured ABS Sheets

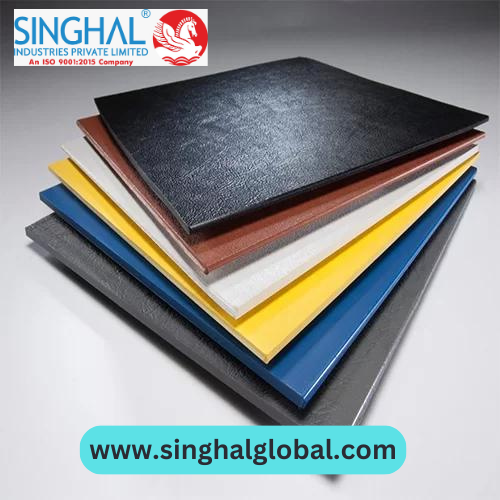

One of the standout features of ABS sheets is their surface finish. While smooth ABS sheets are widely used, textured ABS sheets offer a different dimension of aesthetics and functionality. The texture on these sheets can range from subtle grains to more pronounced patterns, providing a tactile experience along with visual appeal. This makes them particularly suitable for applications where the look and feel of the surface are critical.

Versatility in Applications

Textured ABS sheets find applications in numerous sectors due to their versatility. In the automotive industry, these sheets are used for interior panels, dashboard components, and door liners. The textured surface adds a sophisticated look and feel to the interiors while also offering resistance to scratches and fingerprints.

In the realm of home appliances, textured ABS sheets are used for refrigerator liners, washing machine panels, and vacuum cleaner housings. The aesthetic appeal combined with the practical benefits of easy cleaning and maintenance makes them a popular choice. Furthermore, in the realm of consumer electronics, textured ABS sheets are often utilized for casings and enclosures, providing a sleek and professional finish.

Manufacturing Excellence

ABS sheet manufacturers and plastic sheets manufacturers have perfected the process of producing high-quality textured ABS sheets. The manufacturing process typically involves extrusion, where the raw ABS material is melted and formed into sheets. The texture is then imparted onto the surface using embossing rollers. This precise control over the texture ensures consistency and quality across the sheets.

The innovation doesn’t stop at just producing standard textures. ABS sheet manufacturers continually experiment with new patterns and textures to meet the evolving demands of designers and engineers. This commitment to innovation ensures that textured ABS sheets remain at the forefront of material choices for aesthetic and functional applications.

Durability and Maintenance

One of the key advantages of textured ABS sheets is their durability. The material's inherent toughness makes it resistant to impacts, which is crucial for applications in high-use environments. Additionally, the textured surface helps to hide minor scratches and wear, maintaining its appearance over time.

Maintenance of textured ABS sheets is relatively straightforward. Regular cleaning with mild soap and water is usually sufficient to keep the surface looking pristine. The textured finish also tends to hide dust and fingerprints better than smooth surfaces, reducing the need for frequent cleaning.

Environmental Considerations

As with any plastic material, environmental impact is a significant consideration. ABS sheet manufacturers are increasingly adopting sustainable practices in their production processes. This includes using recycled materials, lessens waste, and implementing energy-efficient manufacturing techniques. While ABS is not biodegradable, its durability means that products made from ABS have a long lifespan, reducing the frequency of replacement and the overall environmental footprint.

Customization and Design Flexibility

One of the most significant benefits of textured ABS sheets is the ability to customize them according to specific design requirements. ABS sheets manufacturers offer a range of thicknesses, colors, and textures, allowing designers to select the perfect combination for their projects. This customization extends to the ability to create complex shapes and forms, thanks to the material’s excellent thermoforming properties.

In architectural applications, for example, textured ABS sheets can be used to create striking interior elements such as wall panels, ceiling tiles, and decorative partitions. The combination of texture, color, and form can transform a space, adding depth and interest that plain surfaces cannot match.

Conclusion

Textured ABS sheets represent a fusion of aesthetic innovation and practical utility. Their ability to enhance the look and feel of various products, combined with their durability and ease of maintenance, makes them an invaluable material in multiple industries. ABS sheet manufacturers and Plastic sheets manufacturers continue to push the boundaries of what is possible with textured ABS sheets, ensuring that they remain a top choice for designers and engineers looking to elevate the aesthetics of their creations. As these materials continue to evolve, the possibilities for their application are limited only by imagination, promising an exciting future for textured ABS sheets in the world of design and manufacturing.

Frequently Asked Questions

1. What are the primary uses of textured ABS sheets?

Textured ABS sheets are used in a variety of applications, including automotive interiors, home appliances, consumer electronics, and architectural elements. Their durability, aesthetic appeal, and ease of maintenance make them suitable for environments where both functionality and appearance are important.

2. How do textured ABS sheets compare to smooth ABS sheets?

Textured ABS sheets offer additional benefits over smooth sheets, including better resistance to scratches and fingerprints, enhanced visual appeal, and a more tactile surface. They are particularly advantageous in applications where aesthetics and frequent handling are considerations.

3. Can textured ABS sheets be customized?

Yes, ABS sheet manufacturers provide extensive customization options for textured ABS sheets. These options include different textures, colors, thicknesses, and even the ability to create specific shapes and forms through thermoforming.

4. Are textured ABS sheets environmentally friendly?

While ABS is not biodegradable, many ABS sheet manufacturers are adopting sustainable practices. This includes using recycled materials and implementing energy-efficient production methods. The durability of ABS also contributes to its environmental benefits by reducing the need for frequent replacements.

5. What maintenance do textured ABS sheets require?

Textured ABS sheets are relatively low-maintenance. Regular cleaning with mild soap and water is usually sufficient. The textured surface helps hide dust and fingerprints, reducing the frequency of cleaning compared to smooth surfaces.

6. How are textured ABS sheets manufactured?

The manufacturing process for textured ABS sheets typically involves extrusion, where the raw ABS material is melted and formed into sheets. The texture is applied using embossing rollers, ensuring a consistent and high-quality finish.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News