Unidirectional Tapes Market: Reinventing the Future of Composite Materials

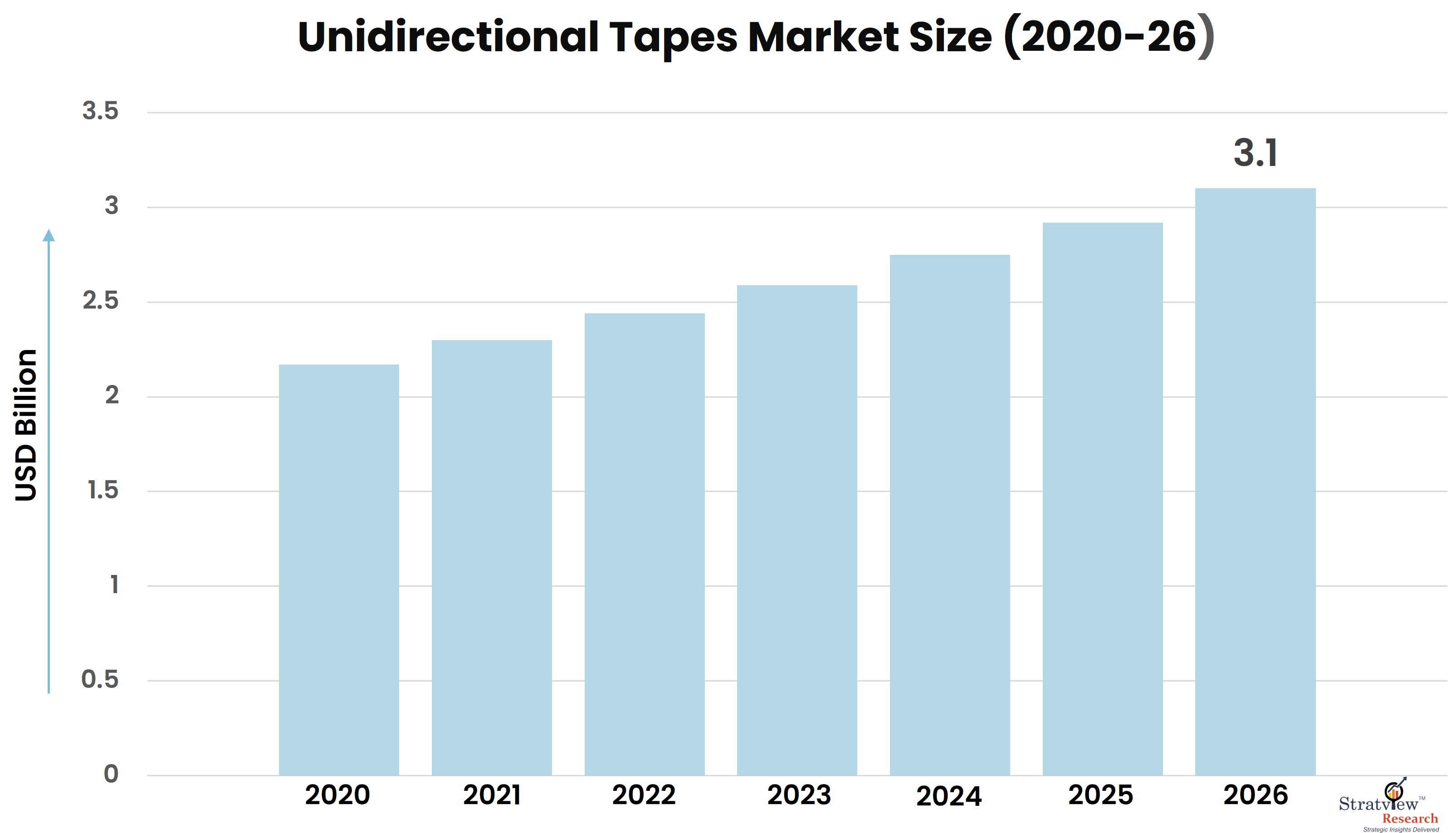

According to Stratview Research, the unidirectional tapes market is projected to grow at a healthy CAGR over the next five years to reach an estimated value of US$ 3.1 billion in 2026.

Innovation is the heartbeat of progress, and in the realm of advanced materials, the rising tide of the unidirectional tapes market is a testament to the power of innovation in motion. Unidirectional tapes, characterized by their unique alignment of high-strength fibers, are revolutionizing industries with their lightweight, durable, and high-performance properties. As the market for unidirectional tapes continues to surge, propelled by technological advancements and evolving industry demands, we find ourselves at the forefront of a transformative wave of innovation.

Unveiling the Dynamics of Unidirectional Tapes

Unidirectional tapes are engineered to provide strength and stiffness in a specific direction, offering superior performance compared to traditional woven fabrics. Composed of high-strength fibers such as carbon, glass, or aramid, these tapes are held together by a polymer matrix, creating a composite material with exceptional mechanical properties. This unique structure makes unidirectional tapes ideal for applications where lightweight and high-strength materials are essential, such as aerospace, automotive, wind energy, and sporting goods.

Riding the Wave of Technological Advancements

The rising tide of the unidirectional tapes market is fueled by advancements in materials science, manufacturing technologies, and design methodologies. Innovations in fiber technology, resin formulations, and manufacturing processes have led to the development of lighter, stronger, and more durable materials, expanding the potential applications of unidirectional tapes across industries.

Automated tape laying (ATL) and automated fiber placement (AFP) technologies have revolutionized the production of complex composite structures, enabling manufacturers to create customized components with precision and efficiency. These advancements have not only improved the quality and consistency of composite materials but also reduced production costs and lead times, making unidirectional tapes more accessible to a broader range of applications.

Opportunities on the Horizon

The rising tide of the unidirectional tapes market presents numerous opportunities for innovation, collaboration, and growth. From material suppliers and manufacturers to end-users and research institutions, stakeholders across the value chain are leveraging advancements in technology to drive progress and unlock new possibilities.

Material suppliers are developing next-generation fibers and resins with enhanced performance characteristics, such as increased strength, stiffness, and fatigue resistance. Manufacturers are investing in advanced production equipment and process optimization to improve efficiency, quality, and scalability. End-users are exploring new applications and design concepts to leverage the unique properties of unidirectional tapes in innovative ways.

Conclusion: Charting the Course of Innovation

As we ride the rising tide of the unidirectional tapes market, we find ourselves on a journey of discovery and innovation. With each technological breakthrough and industry collaboration, we push the boundaries of what is possible, unlocking new opportunities and shaping the future of advanced materials.

Innovation is not just about creating new products; it's about transforming industries, solving complex challenges, and improving lives. As we harness the power of innovation in motion, we chart a course towards a brighter, more sustainable future, where lightweight, high-performance materials like unidirectional tapes play a central role in driving progress and prosperity for generations to come.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News