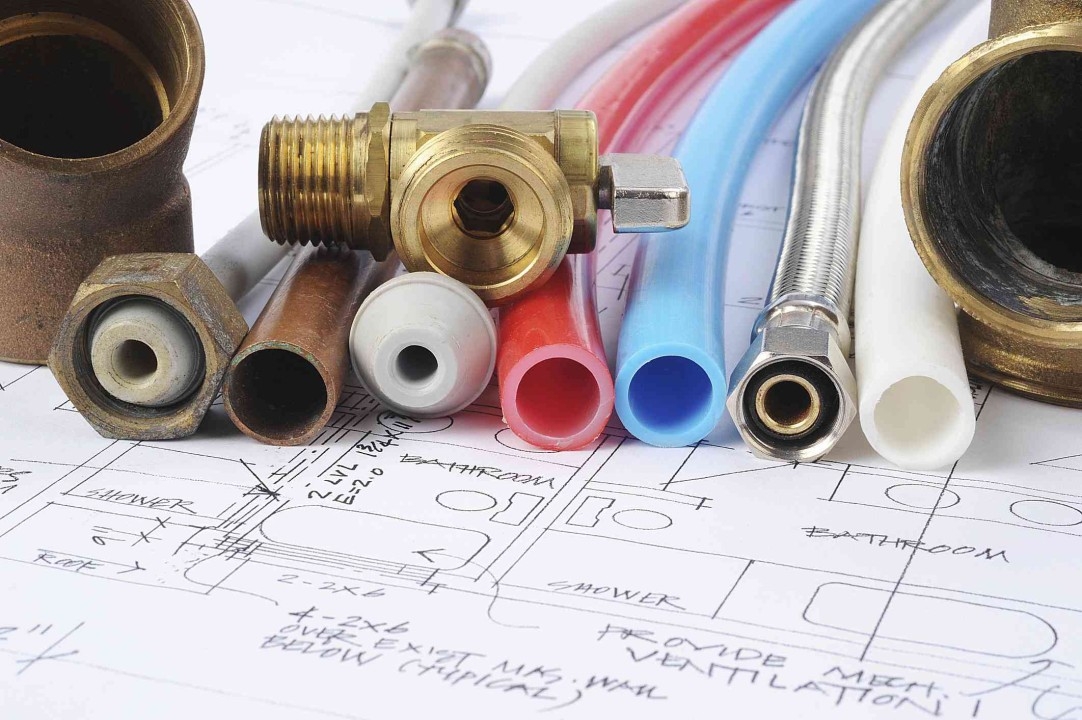

How Does Temperature and Pressure Affect Industrial Hose Selection For Certain Applications

It is essential to choose the right hoses for certain applications. Ratings for temperature and pressure are important factors in deciding whether industrial hoses are appropriate for a certain operation. It is crucial to comprehend these elements in order to guarantee industrial processes' lifespan, effectiveness, and safety.

Temperature Ratings:

Hoses need to tolerate severe temperatures to work well in industrial settings. The range in which hoses may function efficiently without sacrificing their structural integrity is shown by their temperature ratings.

High-temperature hoses are necessary in foundries and chemical processing facilities. EPDM and PTFE are utilized because they resist heat, guaranteeing the hose can withstand the harsh environment.

On the other hand, low-temperature rated hoses become essential in cryogenic applications where very low temperatures are experienced. Because the materials used to construct these hoses don't stiffen or fracture in cold weather, there won't be any leaks or problems with functioning.

Protecting Yourself from Harsh Challenges

Pressure ratings are equally important since they indicate the highest force that a hose is capable of withstanding before failing. High-pressure sectors including manufacturing, agriculture, and oil & gas need hoses with adequate pressure ratings.

Based on pressure ratings, which are often expressed in pounds per square inch (psi), hoses are classed. High-pressure hoses are made for heavy-duty jobs, whereas low-pressure hoses are appropriate for less demanding applications. Hoses with the right pressure rating can withstand the internal pressures of flowing materials without bursting or rupturing.

Synergy for Optimal Performance

Hose performance depends on temperature and pressure ratings working together. Hoses must be carefully chosen for high-temperature and high-pressure applications like steam cleaning and hydraulic systems.

Selecting hoses with dual ratings guarantees that they can handle the combined difficulties of high pressure and very high temperatures. This reduces the possibility of unplanned hose failures while in use and improves safety as well as hose durability.

Taking Material Compatibility into Account

In addition to temperature and pressure requirements, hose materials must be compatible with the chemicals they convey. For a complete solution, temperature, pressure, chemical resistance, abrasion resistance, and flexibility must be considered.

Particular Attention to Changing Conditions

Flexibility and bend radius are important in dynamic industrial situations where hoses must pass equipment or confined places. For a continuous and unhindered flow, hoses that can bend and flex without kinking or collapsing are crucial.

One important factor is the bend radius, which is the smallest radius a hose may bend without causing damage. Selecting hoses with an appropriate bend radius guarantees that they can conform to the workspace's design and avoids early wear and tear from frequent bending.

Conclusion

The correct Mangueras Industriales option ensures smooth operations and protects against industrial risks. Temperature and pressure ratings play a significant role in the careful process of choosing industrial hoses for certain applications. Following these principles ensures hoses may tolerate varied industrial settings.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News