Shipbuilding and retrofitting within the Oil and Gas industry have undergone a transformative shift with the integration of cutting-edge technologies like 3D laser scanning. This article delves into the multifaceted advantages offered by 3D laser scanning in these domains, exploring its impact on enhancing efficiency, precision, safety, and cost-effectiveness.

Evolution of Shipbuilding and Retrofitting:

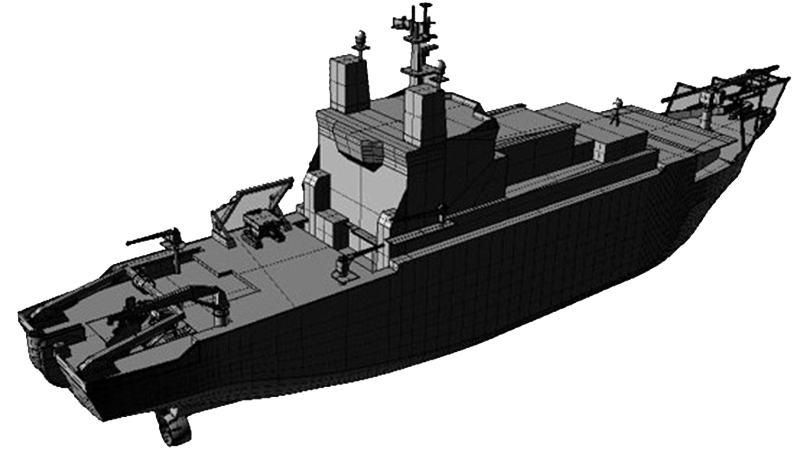

The traditional methods of ship construction and retrofitting often involved manual measurements, blueprints, and time-consuming processes. However, the advent of 3D laser scanning has revolutionized these practices. The technology's ability to capture precise measurements and detailed structural data of ships and offshore structures has significantly streamlined various phases of the construction and retrofitting processes.

Precision and Accuracy in Ship Design:

3D laser scanning enables shipbuilders to capture intricate details of existing structures or components with unparalleled accuracy. Discussing how this technology aids in creating comprehensive digital models that serve as a basis for designing new vessels or retrofitting existing ones. By digitizing the physical environment into high-resolution 3D models, errors are minimized, leading to more precise designs.

Efficiency in Shipyard Operations:

One of the remarkable advantages of 3D laser scanning is its role in optimizing shipyard operations. Detailing how this technology expedites various tasks such as dimensional verification, clash detection, and alignment checks during the construction phase. Moreover, it facilitates efficient planning and resource allocation, thereby reducing project timelines.

Safety Enhancement and Risk Mitigation:

Within the Oil and Gas industry, safety is paramount. Highlighting how 3D laser scanning contributes to enhanced safety protocols by allowing for comprehensive assessments of structural integrity, potential hazards, and risk-prone areas. This technology aids in proactive risk mitigation by identifying issues before they escalate, thereby ensuring a safer working environment.

Cost-effectiveness and Time Efficiency:

Discussing the cost and time-saving benefits associated with 3D laser scanning in shipbuilding and retrofitting. From minimizing rework due to design flaws to reducing downtime during maintenance and repairs, this technology optimizes processes, leading to significant cost savings over the project lifecycle.

Integration of 3D Laser Scanning in Oil and Gas Operations:

Exploring the specific applications of 3D laser scanning within the Oil and Gas sector, focusing on offshore platforms, rigs, and pipelines. Detailing how this technology aids in asset management, inspection, and maintenance activities, ensuring operational continuity and compliance with stringent safety standards.

Future Prospects and Conclusion:

Concluding with insights into the future of 3D laser scanning in shipbuilding and retrofitting, emphasizing ongoing advancements and potential innovations. Highlighting the role of AI, automation, and machine learning in further optimizing this technology for enhanced efficiency and sustainability in the maritime and Oil and Gas industries.

By integrating 3D laser scanning, the shipbuilding and retrofitting processes in the Oil and Gas industry are undergoing a transformative evolution. This technology's advantages in precision, efficiency, safety, and cost-effectiveness are poised to redefine the standards of excellence in these domains.