Virtual Precision: How Online CNC Services Are Reshaping the Industry

Are you trying to find ways to cut costs and make your industrial processes more efficient? You only need to look at CNC milling services on the web! In today's fast-paced world, businesses need options that are easy to use and provide speed and accuracy. That's exactly what CNC services on the internet offer: an easy-to-use alternative to traditional machine shops that offer high-quality cutting services. Online CNC service can give you the competitive edge you need, no matter how big or small your business is—whether you're a big player in the industry or a small company. As we learn more about this interesting topic, let's look at how digital manufacturing can change the way you make things without costing a fortune.

Why and how online CNC machining services are useful and important

Because they have so many benefits, online CNC machining services are necessary in the industrial world today. The factor of convenience cannot be ignored. Online services let you do a lot of different kinds of cutting from the comfort of your own home or office. Going to real machine shops to get bids or talk about project needs is a thing of the past.

Online CNC services are the fastest and most efficient way to get work done. The advanced software and automatic processes on these platforms let them quickly look over your design files and give you accurate quotes in just a few minutes. Not only will this save you time, but it will also promise faster project responses.

With online CNC cutting, you can also cut costs without lowering quality. Most of the time, online service providers have lower overhead costs than standard machine shops. This lets them offer more affordable options. You can also pick from more makers and suppliers, which will make the market more competitive and bring down prices even more.

The benefits of online CNC machining services are ease of use, speed, efficiency, and lower costs. These are all important things to think about in today's very competitive industrial world. No matter how big or small your business is, using online CNC services for digital manufacturing is the first thing you need to do to boost productivity and cut costs. This method should be used by both small businesses that want to make prototypes of new goods and large companies that want to find efficient ways to make a lot of them.

How to Know About CNC Machining: Materials and Methods

CNC machining, which stands for "computer numerical control machining," is a way of making parts that is very exact and uses automated tools and systems. The production industry has changed because of this technology, which has made it more flexible, productive, and accurate.

CNC cutting involves a number of very important steps. In the first step, called "design," engineers use specialized software to make a computer model of the part they want to make. Professionals then turn the plan into instructions that a machine can understand. This is called programming. These are the commands that the CNC machine uses to do different tasks, such as cutting, drilling, milling, and spinning.

Because each job is different, the materials that are used in CNC machining can also be different. Common materials are things like steel, aluminum, titanium, and brass. Plastics like nylon and ABS (Acrylonitrile Butadiene Styrene) are also widely used because they are strong and flexible.

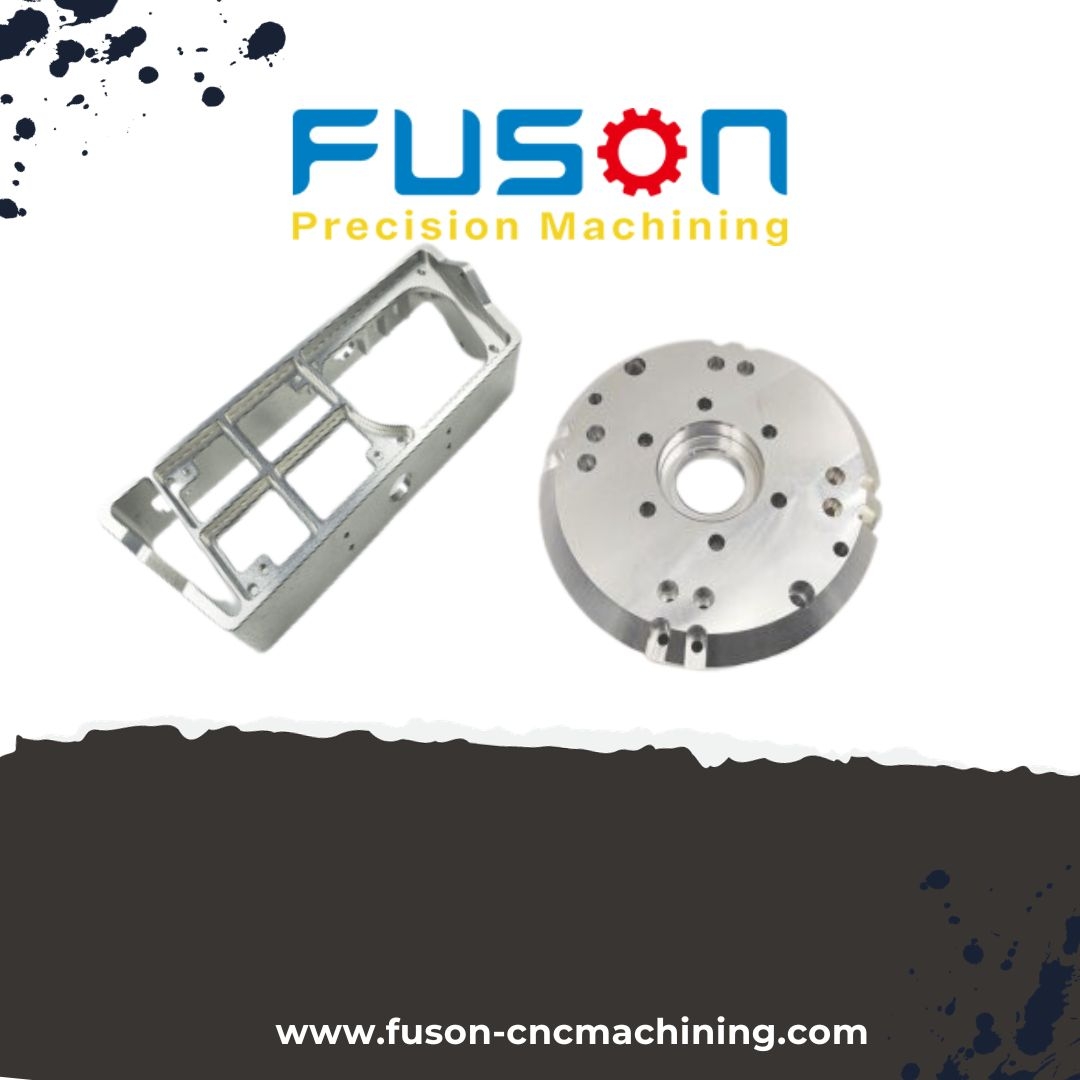

Companies can be more productive and save money by making smart choices about their production needs when they know about the materials and processes used in CNC machining services offered online by companies like Fuson Precision Machining!

Common Things Used for CNC Machining

It is very important to choose the right material for CNC cutting if you want to get the best results. When CNC machines are used, they often work with a few common elements. Let's look at a few of them more closely.

Aluminum is a strong material that is also very light. It is used a lot in a lot of different businesses because it is so useful. It is a great option for precisely building complicated parts because it is easy to work with.

Steel: Steel is normally used in CNC cutting because it is strong and lasts a long time. Because it is very resistant to corrosion and can handle high temperatures, it is a great choice for uses that need strong parts.

Plastics: CNC machines can work with a lot of different types of plastics, such as ABS, polycarbonate, nylon, and acrylics. They don't cost much, are light, and are easy to change to fit special design needs.

When choosing a material, the traits that are wanted, the budget, and the needs of the application are all taken into account. You can get a lot of different materials from an online CNC service provider, which makes it easy to pick the right one for your job.

Pros of Using Online CNC Machining Services

In today's fast-paced and very competitive business world, any manufacturing company needs to find ways to be as efficient and save money as possible. In this case, online CNC cutting services come in handy. These services have many benefits because they use technology and the internet, which can greatly boost output while lowering costs.

Time Savings: Using online CNC machining services can save you a lot of time because you won't have to look for nearby machine shops or wait for quotes. It only takes a few clicks to share your design files and get quick quotes from a number of service providers. With this efficient process, you can speed up the manufacturing process and get products to market faster.

Cost savings: Traditional machining methods often have high setup costs, wasteful material use, and high wage costs. Many of these costs aren't needed because online CNC machining services use automatic methods to cut down on mistakes and make the best use of materials. As the competition grows, their large network of producers also makes sure that prices are low.

You can get cutting-edge technology: If you use an online CNC service, you can get cutting-edge equipment without having to buy expensive equipment. These sites work with reputable manufacturers who have high-tech CNC machines that can make very precise pieces.

Wide Range of Materials: Online CNC machining services offer a wide range of materials that can be used for different tasks, whether you need samples made of aluminum or production parts made of plastic or stainless steel. Their wide range of products guarantees that all of your specific wants will be met.

Quality Assurance: Reliable Online machine shop services use strict quality control methods all the way through the production process to make sure that every part they make meets the strict standards of the industry.

You can count on them to be accurate and consistent with the quality of their goods, since they are known for getting great products to customers on time.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News