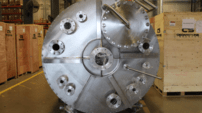

Navigating Choices: Selecting the Ideal Steel Storage Tank for Your Business

Choosing the right steel storage tank for your business is a pivotal decision that can significantly impact operations, efficiency, and overall success. Whether you're in the chemical industry, agriculture, or any field that requires robust storage solutions, the selection process demands careful consideration. This article explores key factors that guide businesses in making informed decisions when it comes to steel storage tanks.

Material Matters:

The first and foremost consideration in selecting a steel storage tank is the material. Stainless steel is a popular choice for its corrosion resistance, durability, and hygiene properties. In industries where maintaining product integrity is paramount, such as food processing or pharmaceuticals, stainless steel is often the material of choice. However, understanding the specific needs of your business and the materials to be stored is crucial. Consider factors such as acidity, temperature, and potential chemical interactions with the stored substances.

Tank Design and Configuration:

The design of the steel storage tank plays a critical role in its functionality. Evaluate the available space for installation and choose a tank design that maximizes storage capacity without compromising accessibility. Conical or cylindrical tanks are common designs, each offering unique advantages. For instance, conical tanks facilitate easier drainage and sediment removal, making them ideal for industries with frequent batch changes.

Size Matters, but So Does Scalability:

Determining the appropriate size of the steel storage tank is essential, and it involves projecting your business's current and future needs. However, scalability is equally important. A tank that can accommodate future growth prevents the need for frequent replacements, saving both time and resources. Consider factors such as production volume, storage duration, and any potential expansion plans.

Regulatory Compliance:

Different industries are subject to various regulations regarding the storage and handling of materials. Ensure that the selected steel storage tank complies with relevant industry standards and regulatory requirements. This not only avoids legal complications but also guarantees the safety of employees, the community, and the environment. For instance, tanks used in the chemical industry must meet specific safety and containment standards.

Cost Considerations:

While cost is a crucial factor, it's essential to view it in the context of the tank's lifecycle. Investing in a high-quality steel storage tank may have a higher upfront cost but can result in long-term savings due to reduced maintenance, fewer replacements, and enhanced durability. Consider the total cost of ownership over the tank's lifespan rather than focusing solely on the initial expense.

Integration with Commercial Steam Cookers:

For businesses in the food processing industry, integrating steel storage tanks with commercial steam cookers is a strategic consideration. Ensure that the tank is compatible with the steam cooking equipment, both in terms of material compatibility and logistical considerations. This integration can streamline operations, providing a seamless flow from storage to processing.

In Conclusion

Choosing the right steel storage tank involves a comprehensive assessment of your business's unique requirements. From material selection and tank design to regulatory compliance and integration with other equipment like commercial steam cookers, each factor contributes to the overall efficiency and success of your operations. By taking a thoughtful and strategic approach to this decision-making process, businesses can invest in a steel storage solution that not only meets their current needs but also paves the way for future growth and success.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News