How to improve the quality of the workpieces produced by CNC machining Analysis of which technology best describes preci

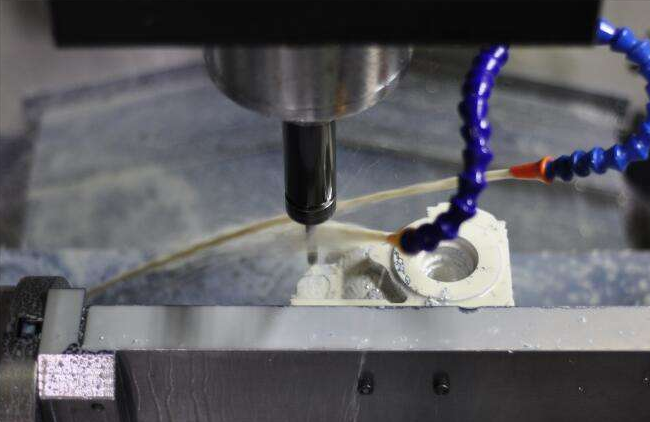

Utilize a calibrator in order to ensure that the tool oscillations fall within the acceptable tolerances before beginning CNC machining. Before beginning machining, the cutter head and locking nozzle should either be blown clean with an air gun or wiped clean with a cloth. This should be done before installing the cutter. Accuracy and quality both have some bearing on the outcome. The program list of the CNC machining files should be normalized. This includes the model, name, program name, machining content, tool size, and feed. In particular, the safe length of the tool holder, the reserved margin for each program, and the indicator lights to be clearly pointed out should all be standardized.

Check the upper 3D drawing after making sure that the CNC machining program list is consistent with the reference angle direction indicated by the mold. This is especially important for the workpiece that has been drilled to transport water because it needs to be verified that the 3D drawing and the level on the workpiece are both consistent with one another. Before beginning machining, you are required to have an understanding of the content of the CNC machining program. The program must have either 2D or 3D maps, and it must be marked with six-sided data consisting of X length, Y width, and Z height. Additionally, the data should be marked cnc machining parts as Z value for the operator's convenience. Check to see if the data is correct after it has been processed, and indicate the tolerance data if there is any room for error.

The processing of steel and copper male smooth knives should be strictly differentiated when using CNC machining tools in a rational manner. Additionally, the amount of smooth knives that are left over should be kept to a reasonable amount in order to improve both the finish of the workpiece and the service life of the knives. When clamping, please pay attention to whether or not the name and model of the CNC machined workpiece match the program list, as well as whether or not the size of the material matches, whether or not the clamping height is high enough, and whether or not the number of calipers being used is sufficient.

The operator needs to have complete command over the speed of the CNC machining, and both the F speed and the S spindle speed need to have reasonable adjustments made to them. It is recommended that the S spindle be sped up whenever the F speed is increased. The speed of the feed needs to be adjusted in various locations. After machining without any problems, it is time to check the quality; after that, it is time to remove it from the machine and finish it perfectly.

Which technology is being referred to in the analysis of the precision machining technology?

Which technology is being referred to in cnc machining service the analysis of the precision machining technology?.

The characteristics of precision grinding, ultra-precision grinding, and mirror grinding all have a significant impact on the quality of the machined surface. Furthermore, the machining accuracy and surface brightness of mirror grinding are superior to those of the various machining processes used in the corresponding machining methods. The process of precision machining involves both high-brightness and high-precision grinding in addition to various forms of precision cutting (such as diamond boring, precision turning, wide-blade precision planing, etc. ). Precision machining typically has a machining accuracy of 100. 1m, a tolerance level that is higher than IT5, and a surface roughness Ra that is lower than 0. 1m.

During the process of precision machining, a very thin layer of metal is removed from the surface of the workpiece using a cutting speed that is either very high or very low, a small depth of cut, and a feed rate that relies on high-precision, rigid machine tools and tools that have been ground to a precise level of accuracy. It should come as no surprise that this process has the potential to significantly impact the accuracy with which the parts are machined. Because the cutting process leaves behind such a small residual area, the negative effects of cutting force, cutting heat, and vibration can be eliminated to a large extent. As a result, the surface deterioration layer that was left behind by the prior process can be effectively removed, and the surface that is left behind after processing is essentially free of residues. Additionally, both the tensile stress and the roughness are drastically decreased, both of which have a significant impact on the quality of the machined surface.

incredibly luminousGrinding processes such as precision grinding, ultra-precision grinding, and mirror grinding are included in high-precision grinding. Grinding that is both high-bright and high-precision requires the machine tool to have a high level of precision as well as rigidity. In the grinding process, a precision-dressed grinding wheel is utilized to ensure that multiple micro-cutting edges of an equal height are generated on each abrasive grain. As a result, the grinding process is carried out on an extremely minute scale. Depth, under the appropriate grinding pressure, very fine chips are cut from the surface of the workpiece, plus the friction when the micro-cutting edge is in a slight state, kneading, smoothing effect, and repeated frictionless polishing in the no-feed polishing stage effect, and then you can obtain a high-gloss surface with high machining accuracy and excellent physical and mechanical properties.

Using CNC processing equipment for processing, which offers high power and good quality; however, if the process planning is not handled properly, it will directly affect the output and even affect the quality along with other issues. The procedure for CNC milling is far too disorganized. It is easy to adjust the tool setting by using one knife, and it is accustomed to general machining. The reason for this problem is that it is afraid of complexity, the programming is simple, the operation and processing are simplified, and it is easy to adjust the tool setting. All of these factors contribute to the problem. Because of this, it is difficult to guarantee the quality of the product, and the production power cannot be utilized to its full potential.

Therefore, CNC machining technicians and operators need to have a comprehensive understanding of CNC machining knowledge, make additional attempts to grasp the relevant knowledge, and select the method of process convergence as much as possible for processing. After the selection process has reached a point of convergence, the amount of time required for unit processing will increase. We arranged the two pieces of equipment so that they would be facing cnc machining services each other, and then we had one person operate both pieces of equipment simultaneously. The effectiveness has been significantly enhanced, and at the same time, the quality has been reliably ensured.

The CNC machining sequence is illogical, and some CNC machining operators frequently arrange the machining sequence in online milling service a manner that is extremely illogical when taking into account the difficulties that are involved in the preparation. In most cases, the CNC machining process is carried out in accordance with the requirements of the general machining process. These requirements include processing the work in the following order: first coarse, then fine; first inside, then outside; and making a reasonable selection of cutting parameters in order to improve both the quality and the efficiency of the work.

Incorrect configuration and utilization almost always result in undesirable outcomes, including overshoot when returning to zero, precision drop, and equipment rail surface strain due to excessive speed setting. It is simple to trigger safety accidents that involve a collision with workpieces or equipment if the route that goes back to zero is not operated with extreme caution. As a result, when considering the use of the G00 command, it ought to be considered in an all-encompassing manner rather than in an arbitrary one.

When it comes to CNC milling, it is essential to place a strong emphasis on improving both the program retrieval and trial operation processes. After the program has been entered into the control system, the operator should use the SCH key in conjunction with the,,, movement keys to search for disapproval and acknowledgement. If necessary, the operator should also correct the program in order to ensure that the program is accurate. At the same time, prior to the official execution of the program processing, it is necessary to successfully complete the program test run in order to validate whether or not the processing route is the same as the route that was planned.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News