In the course of fabricating various mechanical componentsWhat are the requirements that need to be met in order for a p

Handling gloves, waiting for them to dry, and then isolating them with cotton are all steps that need to be taken in order to successfully complete this task. When this condition is met, only then can we say that the task is finished. In order to provide even more illumination on the matter, it takes into account both the acceptance requirements as well as the acceptance procedures. Visual inspection to determine whether or not the surface of the machined parts has been damaged, rusted, or bruised; to determine whether or not the thread shape and angle are correct; and to determine whether or not the finish of the machined parts satisfies the specifications of the drawing. It is necessary to compile extensive records in order to use them in the future in the event that any of the problems that have been outlined above are found. This is because using these records will be necessary. The material, specifications, and quantities of the parts that are being processed at any given time are meticulously compared to the drawings throughout the entirety of the manufacturing process. In addition, during the course of the procedure, each individual component is subjected to a check and a double check. At each and every stage of the process, the assembly must be carried out in a manner that is in full and complete conformity with the regulations and procedures specified by the final assembly drawings. It is of the utmost importance that comprehensive records be kept throughout the entirety of the process of quality acceptance. In the event that there is a problem with the quality of the processed parts, the outsourced processing unit needs to be given written notification of the specifics of the issue. In the event that there are any particular requirements, you will have the ability to locate the processing unit.

For each type of processing, there is a specific order in which the processing steps need to be completed in that must be adhered to. The processing step is one of them; therefore, in order to have a better understanding of the processing sequences of precision mechanical parts, what are the other steps?the very best that precision machinery has to offer.

The arrangement of the processing sequence of the fine parts should be thought out according to the structure of the part and the condition of the blank, as well as the requirements for positioning and clamping, and the most important thing is to ensure that the rigidity of the workpiece is not compromised in any way at any point in time while the process is being carried out.

When there are multiple processes that are halted in the same device, the order of the processes should be determined by which one causes the workpiece to suffer the least amount of rigid damage. When there are multiple processes that are halted in the same device, the workpiece should be rigidly damaged. When there are multiple processes that are halted in the same device, the tool centralized sorting method involves dividing the process in accordance with the tools that are being used, and then using the same tool to process all of the parts on the part that can be finished. This method is used to handle situations in which there are multiple processes that are halted in the same device. This approach is predicated on the concept that the overall procedure can be completed more quickly if all of the parts of the component are worked on with the same tool. maximizing the use of the second and third knives to their full potential in order to complete the remaining tasks by making full use of the capabilities each knife possesses.

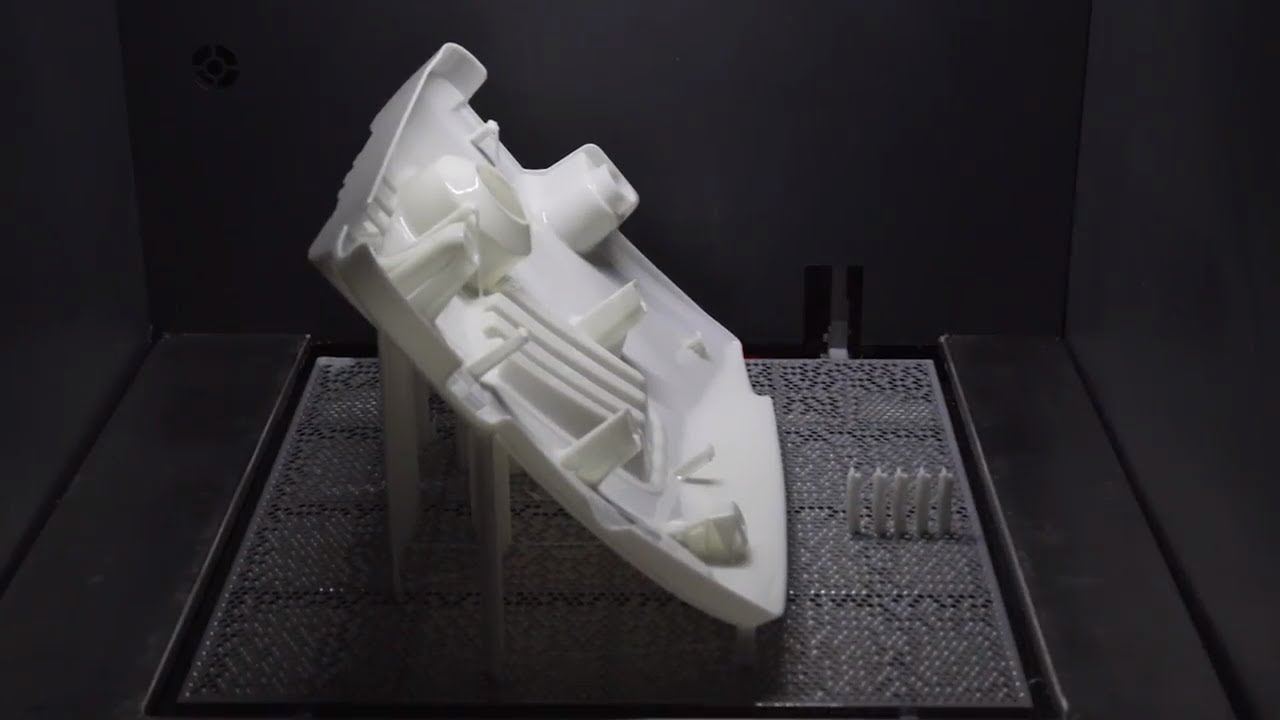

When dealing with components that require a significant amount of processing, the processing part itself might be subdivided into multiple parts depending on the structural characteristics of the component parts themselves. This is something that can happen when dealing with components that require a significant amount of processing. These structural characteristics might include an inner shape, an outer shape, a Plastic Machining Services curved surface or a flat surface, and so on and so forth. If you are looking for a professional CNC processing manufacturer, Xiaobian suggests that you make a comprehensive decision based on a number of criteria, such as the qualification and strength of the manufacturer, the customer case of the manufacturer, the manufacturer's technical level, the manufacturer's reputation and reputation, and the quality of the manufacturer's after-sales service. If you are looking for a professional CNC processing manufacturer, Xiaobian suggests that you make a decision based on these and other criteriaIf you are looking for a professional manufacturer who specializes in CNC processing, Xiaobian suggests that you go in this direction if you want to find what you're looking for.

The degree of precision achieved by the machining plays a significant role in determining the total number of products that can be manufactured. Despite this, the actual parameters that are obtained through any method of machining will not be accurate. There is no exception to this rule. It makes no difference which approach is taken because this is always the result. The answer to this question can be discovered by investigating the role that the component plays in the system. In a manner that is directly proportional to the size of the flaw, the accuracy of the machining will suffer; on the other hand, the accuracy of the machining will improve as the flaw size gets smaller.

Adjustments to the trial cutting method are made by first cutting using the trial cutting method, then measuring the standard, then adjusting the amount of knife bite the tool has, then cutting by cutting, then retrying cutting, and so on, until the required standard is met. This process is repeated as many times as necessary until the required standard is met. This procedure is carried out an infinite number of times until the predetermined standard has been attained. It is possible to achieve the required standard by employing the adjustment method, which entails making an initial adjustment to the relative orientation of the machine tool, fixture, workpiece, and tool. This allows for the standard to be met. To accomplish this, simply follow the instructions that have been provided. The selection of the deceleration transmission, an essential step in the process, is where the process of ensuring that the transmission is accurate gets underway. This is because the selection of the deceleration transmission is an essential step in the process. The transmission ratio of the transmission pair that is located closer to the end should be lower, and the level of precision of the end piece should be higher than that of the other transmission parts. This is because the end piece transmits more force than the other transmission parts do. This is due to the fact that the end piece Plastic Machined Parts transmits a greater force than the other components of the transmission.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News