When it comes to making a decision what aspects of the situation do you need to take into consideration in order to ensu

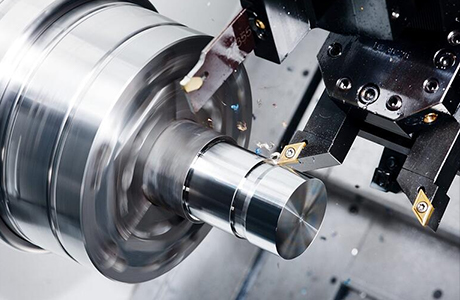

When it comes to the production of machined parts, the accuracy of the machining process is frequently one of the most important factors in determining the overall quality of the machined components. This is because the overall quality of the machined parts is directly correlated to the accuracy of the machining process. Machining precision components on a computer numerically controlled (CNC) machine is in and of itself an exceptionally challenging machining method. This is due to the fact that the first choice is a more expensive alternative. How do we go about selecting an appropriate provider, and what characteristics of potential service providers should we center our attention on when making this choice?When there are two options available, our standard recommendation is to select a good tube rather than a good one when there is a choice that needs to be made between the two.

Your first order of business should be to devise a model that can be applied to the task of determining which vendors provide the most desirable features and benefits, and then use that model to rank the vendors in order of desirability.We have compiled a list of points by making use of the information that was provided by each of the purchasing managers, and these points are based on the information that was provided by the purchasing managers.Make sure that the total amount of interest is factored into your calculations.

When looking at the requirements for the processing of CNC parts, you will notice that the parts that have low precision requirements and a large number of parts are primarily looking for suppliers who have good coordination, low prices, and a large production capacity. This is because these parts require a lot of individual pieces to be processed.This is due to the fact that the processing of these parts requires a substantial number of individual components to be completed..

2. In addition to this, in order to ensure that they are the ideal match for one another, it is dependent on the positioning of the suppliers, or the customers that they aim to serve, respectively. This is done in order to guarantee that they are the best possible match for one another. This is done in order to ensure that they are the ideal complements for one another, which is why it is done. On the basis of this, we hope to be in a position to provide the entire industry chain service in the field of robotics for a variety of businesses, universities, and scientific research institutions located all over the world. This will allow us to meet the demands of the global market. The skill of being able to comprehend what one observes with one's own eyes. Your requirements for suppliers ought to serve as the compass that guides your choice of supplier, and you ought to go with one that possesses capabilities that are in line with those requirements. In other words, your choice of supplier ought to be guided by your requirements for suppliers. To put it another way, the standards that you have established for the vendors online machining services that you collaborate with should serve as the basis for your choice of vendor.

5. Don't forget to factor in how this will affect the company's bottom line when making your decision.

It depends on the supplier's equipment value, average output, efficiency, procurement cost, per capita output, management cost, etc.It is necessary to have knowledge of the processing technology on the one hand, and it is necessary to be able to collect market rates and material costs, in addition to having the ability to perform cost analysis, on the other hand.Therefore, maintain an alert awareness of the activities occurring in your immediate surroundings.This is due to the fact that there are a wide variety of distinct categories comprising the pool of potential suppliers.Take into consideration the astoundingly high level of performance that has been displayed, which has been exceptional.Examine the level of quality awareness that the company that is providing the service possesses, as well as the presence or absence of on-site process inspection, sampling inspection, and final inspection, and make sure that this matter is attended to.Because people are the foundation of everything else, you need to investigate the level of experience, promotion, and mobility that these individuals possess within the industry. This is something you should do because people are the foundation of everything else.You ought to engage in this activity due to the fact that people are the basis upon which everything else is built.(Within the company, there are many different levels of management that you can choose from. Take a look at all of your options.)

In the machining and sheet metal production industries, it is essential to determine whether or not there are established protocols for the disposal of hazardous chemicals and the administration of environmental impact assessments. In addition, it is essential to determine whether or not such protocols are followed.

The vast majority of the time, a linkage with three axes is used; however, it is possible to convert it into a machining center with four-axis, five-axis, seven-axis, or even more linkage axes by making a few adjustments to it. Increasing the number of linkage axes is the method used to achieve this goal. The three-axis linkage is by far the most online cnc machining service common type of linkage used in contemporary machinery. When this is done, there is a possibility that the machining center's processing scale as well as its capacity will both increase. Take for instance the following:Take into consideration the following as an example:Because of this, it is now possible to replace the tool in a timely manner, which guarantees that the processing quality of the parts will be maintained even in the event that the tool will need to be replaced at some point in the future.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News