Finding The Best Price About The Waste Plastic Pyrolysis Plant

The waste plastic pyrolysis plant is a vital item of equipment for just about any recycling operation. This plant is perfect for the environment mainly because it takes waste plastic and turns it into oil. These plants prevent tons of plastic from entering the landfills and their simplicity of operation and affordable cost means they are an incredible selection for any business(máquina de reciclaje de Beston).

Plastic waste is actually a major cause of pollution. This waste gets into the landfills and also the water and results in a lot of problems on the planet. The plant takes this waste and prevents it from causing further pollution by turning it into oil. In fact, 30 percent of trash is plastic so that you can find out how valuable this machine is.

This plant will take almost all kinds of plastic including bottles, containers, plastic wraps, car parts, and much more. The plant(planta pirolisis) lets you take trash and change it into money by transforming it into oil. These appliances might be exported to any country and their affordable price makes them a fantastic option when you want to transform tons of plastic into oil.

The expense of the plant depends on the dimensions you need. You can even get the plant customized for the individual needs that may add additional costs to the price tag on the plant. The company will work with you so that you can obtain the plant which is the best fit to your business.

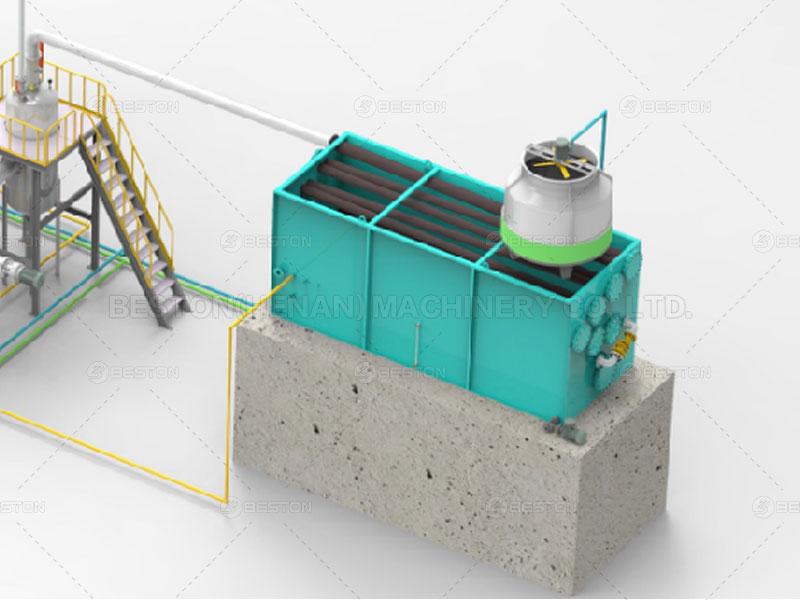

You can find three different os to choose from, batch, semi-continuous, and full continuous. Every machine comes with safety devices that ensure that the machine(planta pirolisis neumaticos) remains safe and secure to use and will quickly be turn off if needed. The machines also have advanced deducting systems which prevent any pollution from entering the planet. The machines are self-contained, which means they won't be a menace to environmental surroundings.

The machines are designed to use small amounts of power and gas as well as the energy which is used is recycled so that you can keep your energy bills down when using this machine. The machines can produce large amounts of oil which can be used for heating and can also be sold. The oil can also be processed again and changed into gasoline.

Just how the machine operates is straightforward. The plastic is first dried and crushed inside a dryer device so that all the pieces are small, and uniform. Then this waste plastic is fed to the machine with a conveyor belt. When the plastic is in the reactor it really is heated up to the oil gas is produced. Finally, the oil gas is cooled off then discharged and collected.

The equipment is efficient and it is fast. It could produce plenty of oil every hour and you will easily market it and create a large profit. The oil works extremely well in a range of ways, and you can make a refund using this type of machine fast and start making a profit right away. The waste plastic plant(planta de reciclaje de neumaticos) is great for the planet and it will make you money.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News