The present invention relates to improved Probe Card Assembly manufacturing and design. It is not limited to the exemplary embodiments described below. In general, the present invention is directed at the fabrication of probe cards that utilize a decoupling plane.

In some cases, these planes can be formed by selectively connecting platelets. FIG. 12 illustrates this process, in which platelets are connected to form a larger decoupling plane.

Vertical Probe Cards

A new business model is emerging in the wafer test with the consolidation of Semi Probes Inc., its vertical probe card manufacturing operations. They did not disclose how many jobs will be affected.

One technique for vertical needle-type probe card manufacturing involves a two-piece structure. One is the upper guide plate 5 which is positioned above a lower guide plate 6. The upper guide plate is made from the same silicon compound material as an IC chip wafer.

The upper guide plate has a conductive rubber sheet and contact portion 4d to enable easy contact with a conductive rubber sheet. Both pieces are placed on a conductive shim.

Solder Bump Vertical Probe Cards

If you're planning to purchase a new solder bump vertical probe card, you should know that there are a few things to look for. The first thing to look for is the type of tip on the probe.

While the most common type of tip has a flat edge, you should also look for a probe with a pointed edge if you're planning to use it on an aluminum surface. The type of tip also depends on the material of the probe.

Several types of Vertical Probe Cards are available. One of the most popular ones is made up of a set of pins that you can replace separately if they become damaged.

Another type of vertical probe is made up of contact bumps lithographically defined on a flexible membrane core. Both types of probes are used for similar testing. This type of probe is more expensive than a standard cantilever model.

Epoxy Probe Assembly

The Epoxy Probe Assembly is a critical component of any specialized instrument. The plastic or metal ring supports the probes, and a special adhesive holds them in place. The adhesive has many desirable properties, including being electrically non-conductive, resistant to high temperatures, and adhering to the probes.

There are several types of epoxies used in this industry, including some that are designed for high-temperature applications and those that do not leak.

FEA calculations show that the stress distribution between two ceramic rings is proportional to their square roots. This value is called the Von Mises value, and it is the square root of the total stress components.

Moreover, the thermistors in the Epoxy Probe Assembly should be tested for functionality and performance before the assembly is installed. The thermistors should be properly placed, and the probe-card ring should be thoroughly seated.

DC Probe Cards

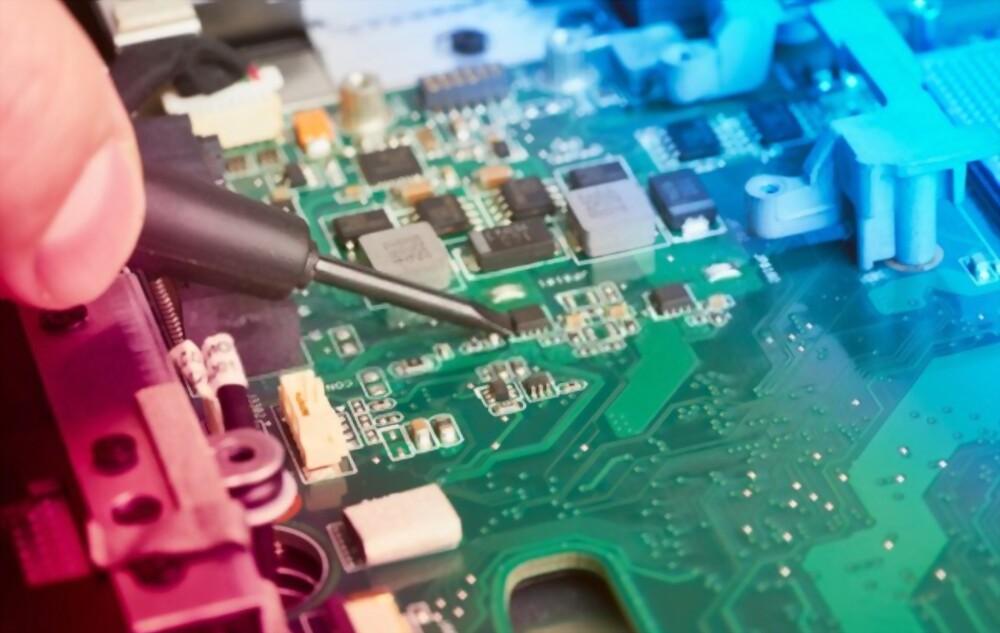

The manufacturing process of a DC Probe Cards involves the construction of a circuit board, a supporter, and a series of conductive probes. Each probe is connected to its corresponding connection via a conductive through hole 20 or a wire 26.

The probes are then placed on a testing machine and tested to determine their functionality. DC Probe Card Manufacturing is an ideal way to develop and manufacture these test tools. Here are some tips to make the process go as smoothly as possible.

The manufacturing process of a DC Probe Card comprises common activities, such as selecting the right decoupling planes. Moreover, probe card assembly involves several steps, such as selecting a test algorithm and selecting a tester. After completing these steps, a semistandard probe card assembly is manufactured.

This prefabricated DC Probe Card Assembly is the most effective method for manufacturing and designing a DC Probe Card. As a result, it reduces the overall manufacturing time by about 50%.