Pyrolysis oil, that also goes through the names of bio-oil or bio-crude, is a kind of synthetic fuel that is certainly still under investigation and research like a "substitute" for petroleum. Pyrolysis oil is extracted by way of a technology(Beston) that concerns turning biomass into liquid and gas. The dried biomass undergoes destructive distillation inside a reactor once the temperature reaches around 500°C, followed by subsequent cooling.

Bio-oil or pyrolytic oil is a form of tar that typically contains degrees of oxygen that are excessive to become considered a hydrocarbon. For that reason, this product is clearly different when compared with similar kinds of petroleum products.

Pyrolysis oil is normally extracted from waste plastic or waste tires or perhaps municipal waste in a pyrolysis plant. These plants convert waste tires or plastic to oil. The method involved converts waste plastic or tires to pyrolysis oil (fuel oil) and fails to cause pollution or solid waste. The very last product at the most pyrolysis plants(maquina para pirolisis de plasticos) is oil gas, carbon black, and fuel oil.

The raw materials that include waste tires or waste plastic are heated within a reactor. The raw materials then vaporize, along with the vaporized oil gases travel into a condenser in which the materials are then converted into fuel oil. Any oil gas that cannot condense is recycled and after that used like a heat source to the reactor.

Pyrolysis oil can be a product which is used mainly as fuel oil in industrial settings for example steel factories, cement factories, construction heating, and boiler factories. This oil is just like NO.2 diesel. Through the entire process of direct combustion that takes place in either a furnace or boiler, pyrolysis oil is usually used for producing heat.

Pyrolysed(trituradoras de llantas) oil or bio-oil has several applications. The oil that is produced should first be tested to ensure it is actually matching approximately the oil that may be currently used. The 3 main applications include:

- Being a fuel source in fuel-fired boilers

- As a fuel source in generators

- In engines that utilize either diesel or petrol

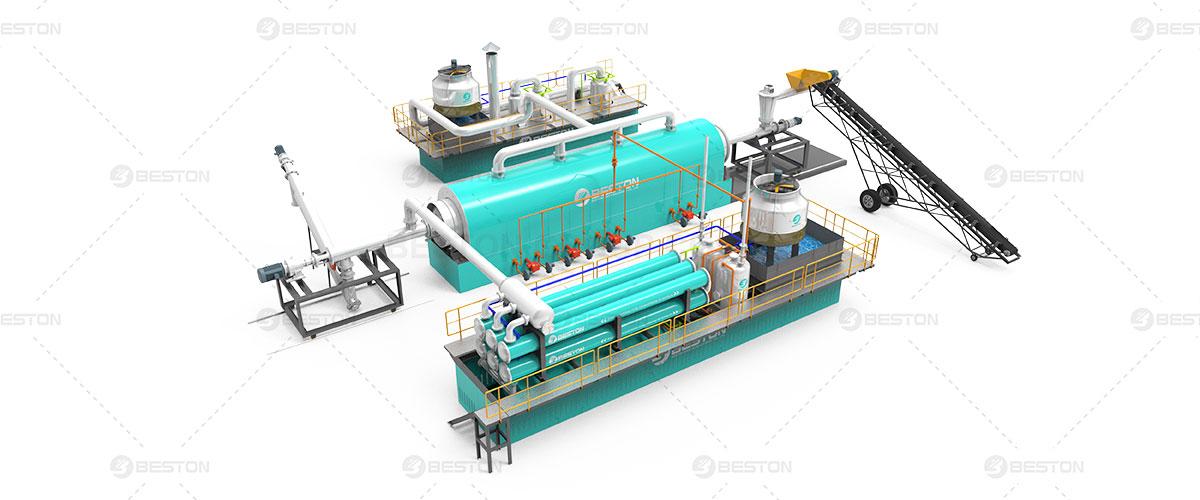

Waste Plastic Or Tire Pyrolysis Equipment

Because the prices of a product for example oil continue to rise, many businesses are starting to change to pyrolyzed oil. This bio-oil type is classified as a gross oil which is already utilized as a type of industrial fuel oil. Bio-oil can replace fuel oil directly for boiler or industrial heating. Some of the common industries that make use of this device include steel plants, glass factories, and cement factories. For people who are interested in "refined" diesel oil, pyrolysis oil distillation equipment becomes necessary.

Since pyrolysis oil can substitute fuel oil useful for boiler or industrial heating, nowadays there are several manufacturers that offer quality waste plastic or waste tire pyrolysis equipment(planta de pirolisis) that could easily convert these common waste materials into useable pyrolysis oil. This kind of waste plastic or waste tire pyrolysis equipment offers businesses with ways to achieve maximum recovery and also reusing resources offering an increased amount of environmental and economic benefits.