Investing In A Fully Automatic Egg Tray Machine In Russia

For those who have made the decision to get started on an egg tray making business(maquinas embaladoras de carton) in Russia this current year, the necessity of researching the appliance options available for you to you personally thoroughly can not be overstated. All things considered, you desire to make sure that you invest in a paper pulp molding machine that is certainly set to provide your organization the best ROI rate within both the short and long-term. One of many worse actions you can take when entering the eco-friendly food packaging manufacturing marketplace is to overspend on inefficient, unreliable machinery.

There are lots of egg tray making machine(Máquina moldeadora precio) models in the market, so weighing within the advantages and disadvantages of each may take a moment. In addition, there are several different third-party suppliers in operation offering generous discounts on machines from established manufacturers. Consequently vendor scientific studies are also important. You don't desire to risk placing an order using a rogue middleman.

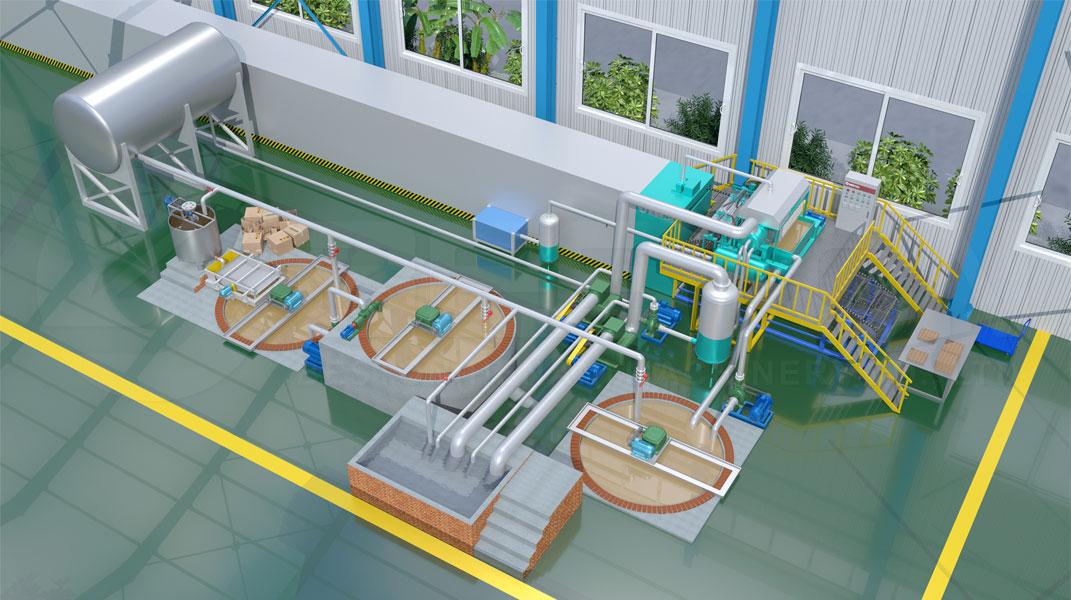

Before you start looking for an egg tray making equipment, it will be a smart idea to learn a little bit more regarding the equipment. An egg tray making machine is actually a unit of heavy-duty machinery that converts waste paper into molded pieces like coffee cup trays, fruit trays, egg trays, and seed cartons. Modern machines integrate all stages from the manufacturing process. Those four stages are pulping, wet mold transfer, drying, and packaging. The output of high-quality final products is dependent upon all four stages of production going well.

The price tag on an egg tray making machine is susceptible to a variety of parameters including automation level, mold quantity, drying system type, production output rate, operation mode, power requirements, operational lifespan, etc. If you need a machine created from high-grade components, you routinely have to pay a lttle bit extract. Over the future, however, purchasing a top quality machine will probably possess a bigger payoff. It is because a likely to need to cut back of maintenance costs, repair work, and replacement parts. Furthermore, a better quality egg tray machine is probably going to go longer.

The energy efficiency rating of egg tray making equipment(https://www.bestoneco.com/maquina-moldeadora-de-pasta-de-papel/) is a crucial specification to consider. The running costs of your respective business will largest depend on the fuel burn rate of your own machine, as the raw materials necessary for paper egg tray manufacturing are incredibly cheap. Most modern egg tray makers run on a range of fuel sources, including LPG, wood, diesel, coal, charcoal, biomass, gas, etc. You can find out the ability usage of different machine models by downloading data specification sheets. Machines with integrated heated drying systems will probably utilize the most energy.

The way forward for fully automatic egg tray machines(bestoneco.com) in Russia is looking bright. It's predicted that a great many more manufacturers of these machines will begin operation in america within the future years. Furthermore, it's likely more and more people are going to create paper pulp egg tray making businesses in Russia because the eco-friendly food packaging industry increases in profitability.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News