There are several benefits associated with tyre pyrolysis(equipo de pirolisis) equipment from Beston Machinery. The key benefit is the equipment allows waste management businesses to recoup valuable resources from scrap road tires in the commercially viable way, reducing the quantity of non-biodegradable waste delivered to seafills and landfills annually. In past times, the only way to handle the used tire waste would be to burn it, which contributed to a great deal of atmosphere pollution, or send it to landfill sites where it will dominate 80 years to degrade. Now, due to rubber pyrolysis machines, the waste might be transformed into various commodities inside a non-pollution generating way.

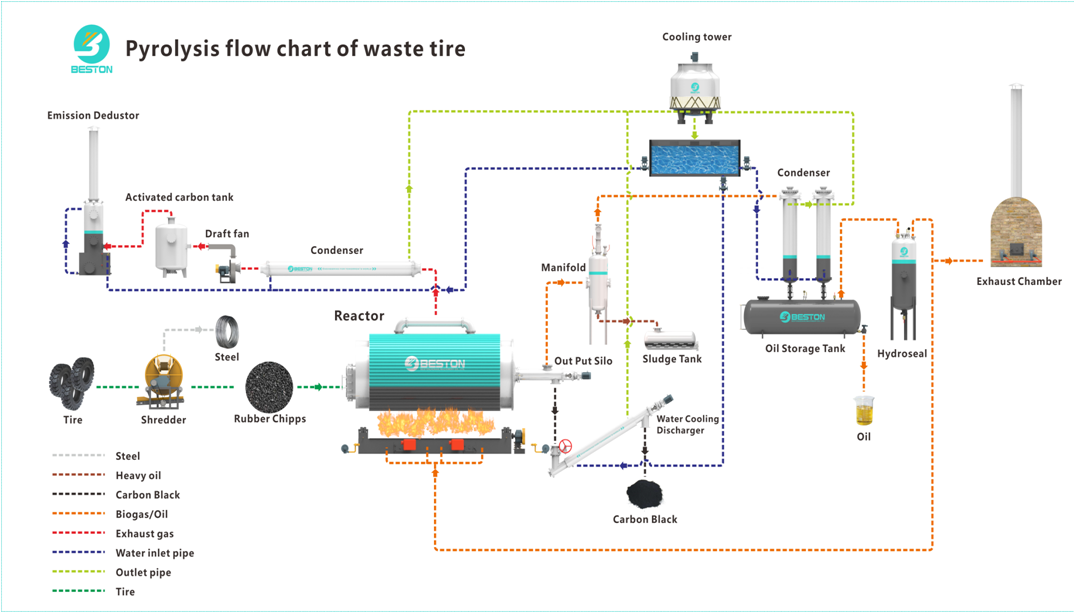

The four key resources taken from used tires by pyrolysis machines (https://www.bestoneco.com/planta-de-pirolisis/)are carbon black, pyrolysis oil, combustible gas, and steel wire. The pyrolysis oil recovered from tires could be available in its raw state as fuel to heavy industries or it can be turned into diesel oil and gasoline using distillation machines. The carbon black recovered from used tires is specially valuable for the chemical industry and wastewater treatment industry as it can be easily transformed into activated carbon.

Beston can be a top-rated manufacturer of tire pyrolysis plants and they currently have four different types for sale. A pair of the pyrolysis plants they manufacture employ batch working method designs, whilst the other two models employ semi-continuous and fully continuous working method designs. Those trying to process over 20 tons of tire waste(maquinas trituradoras de llantas) each day, should opt for the BLL-20 rubber pyrolysis plant, which is actually a fully continuous pyrolysis reactor using a daily capacity of 20-24 tons.

One of the primary advantages of zero-pollution top quality used tire pyrolysis plants from Beston Machinery is they are offered to customers all across the globe. Several of the manufacturer's recent buyers come from South Africa, Germany, the England, South Korea, Egypt, Jordan, holland, and Norway. In October, 218, the maker even sent a plant towards the Phillippines. Beston is actually a go-to choice for many individuals from the tyre recycling business since their equipment makes a high oil yield.

Beston Tyre Pyrolysis Equipment Unique Features

• "Three in One" System: This systems combines the condenser unit, hydroseal and oil tank into one integrated system. Some great benefits of a 3-in-1 integrated system include easier maintenance, fast assembly, optimal condensation effects, smaller area requirements, non-clogging properties, increased operating safety, and reduce transportation costs. Beston has tested the unique system extensively under extreme conditions, so make no mistake the technology is proven. In reality, the 3-in-1 system is what makes Beston tyre pyrolysis plants some of the biggest sellers in the business.

• Dedusting System: Beston pyrolysis (Beston (Henan) Machinery co.Ltd)plants' dedusting systems are designed to make sure the plants emit zero toxic emissions into the atmosphere. Several of the cleaning technologies incorporated into the dedusting systems include water spraying, water washing, activated carbon adsorption, and ceramic ring adsorption. Those planning to match the strictest emission standards should choose an activated carbon adoption tower. Such a tower with a rubber pyrolysis plants means the plant can match the best EU emissions standards.