Precision in Layers: The Art of Manufacturing Stainless Steel Shims

Small though they may be stainless steel shims demonstrate critical importance to the performance and precision of numerous machines together with structures. Stainless steel shims serve three vital purposes in various machine applications including aerospace along with automotive as well as industrial machinery and construction sectors by enabling attaining perfect alignment and spacing adjustment for minimizing wear. Which strategy producers implement to create these vital elements?

The Manufacturing Process

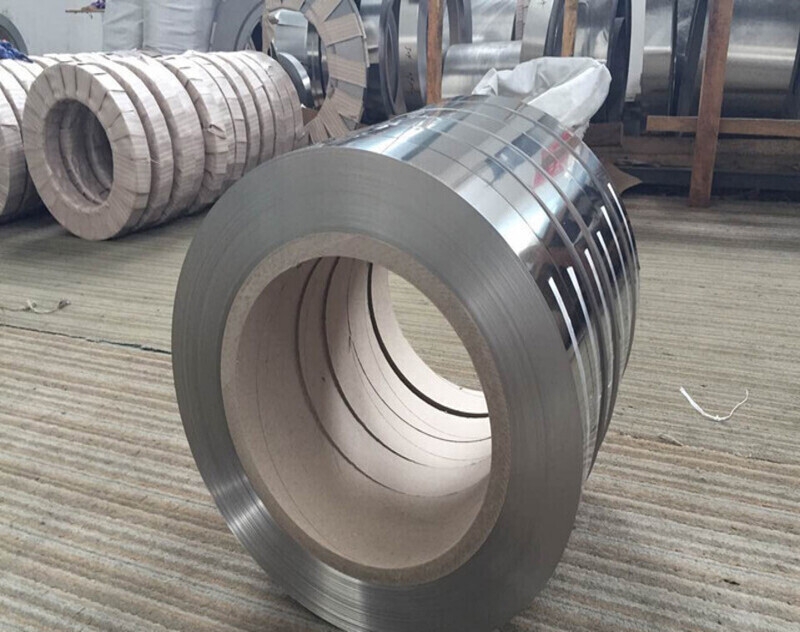

The production of stainless steel shims requires choosing appropriate stainless steel grades including 304, 316 or 321 according to corrosion needs as well as strength and temperature requirements. After selecting the material it receives precision cold rolling treatment until it reaches the desired thickness which can be at the level of microns. The needed equipment consists of sophisticated devices and requires precise operational parameters during this production step.

Finishing & Quality Control

The material receives heat treatment that serves to reduce stresses inside and develop improved mechanical performance. After leveling and flattening operations manufacturers proceed to slitting or shearing operations for achieving the required shapes and sizes. Multiple manufacturers can perform die-cutting or laser-cutting for making complex shapes and sophisticated specifications.

The quality control process maintains its vital position during every stage of shim production. The verification process for dimension measurements at manufacturing facilities utilizes tools which include micrometers alongside digital calipers and thickness gauges. Surface finish combined with flatness receives inspection for attainment of performance requirements during high-performance applications.

India's Technological Edge

The rise of technological innovation leads Indian manufacturers to adopt automation systems combined with quality control standards needed for international markets. The combination of increased productivity and cost-efficient quality performance represents the manufacturing benefits of these processes.

The manufacturing process of shims combines expertise in metallurgy with precision engineering and precise quality monitoring requirements. Such a component operates without attracting notice because it delivers quiet operation to intricate systems.

- Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- News